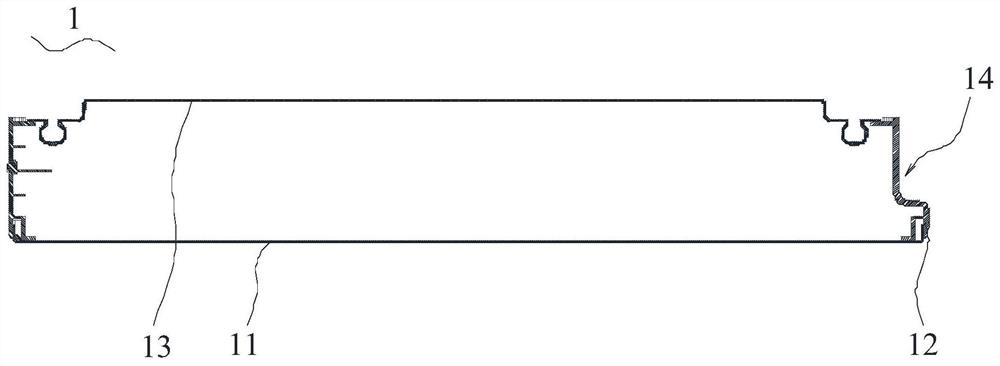

Foaming mold of refrigerator door body

A technology for foaming molds and refrigerator doors, which can be applied to household appliances, other household appliances, and household components, etc. It can solve problems such as waste of materials, increase in production processes, and errors in placement positions, so as to reduce costs and increase yields , The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

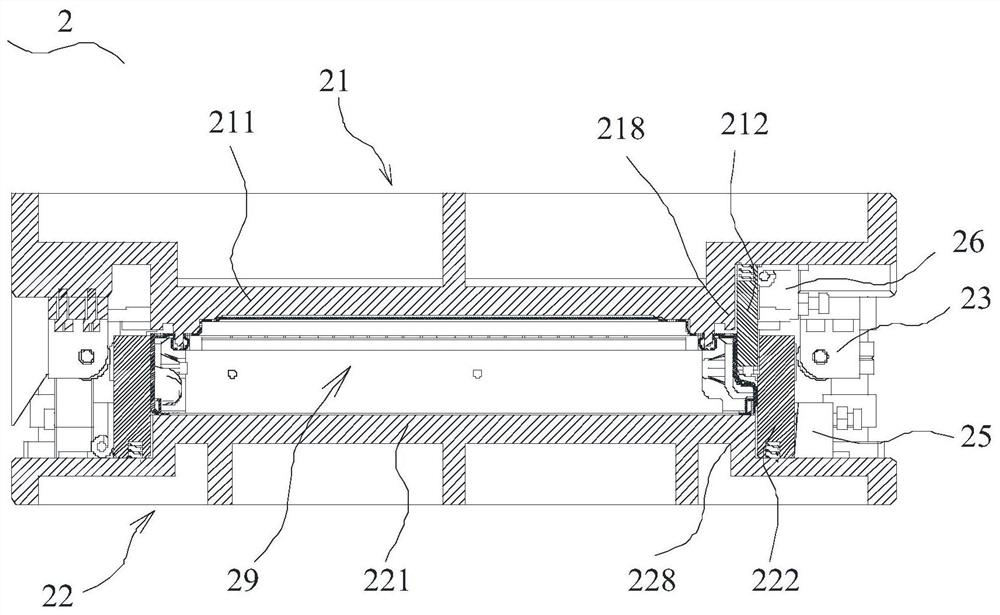

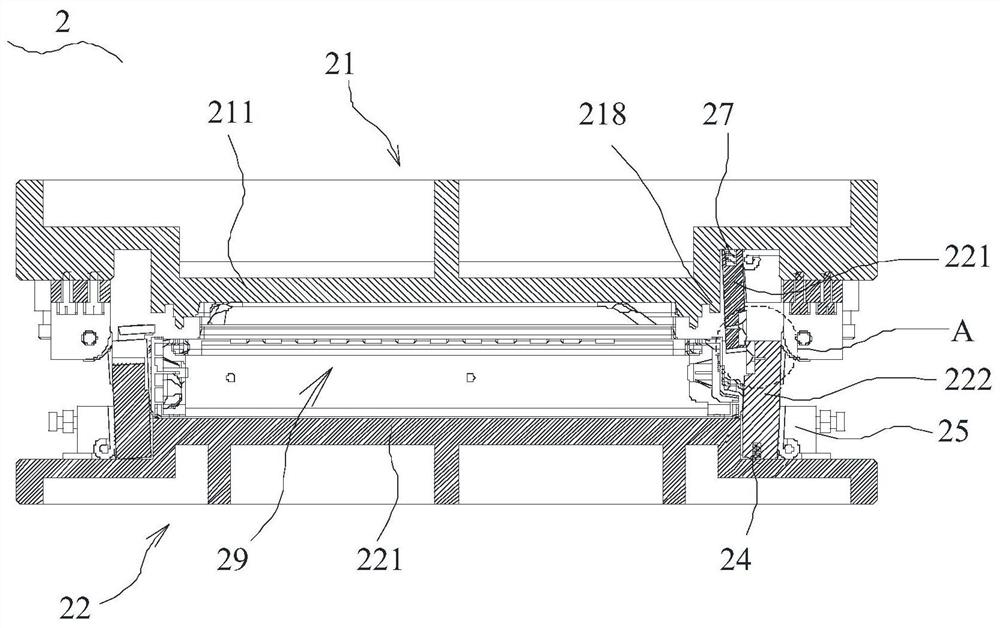

Embodiment Construction

[0030] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

[0031] In the related art, there are steps on the upper end cover or lower end cover of the refrigerator. When foaming, after the door body is placed in the lower mold of the foaming mold, it is necessary to manually place a piece of tooling on the step of the corresponding end cover to A lateral force is applied to the corresponding end cap, so that the end cap can engage with the door shell and the door liner. This method is likely to cause errors in the placement position, and it is easy to cause deformation of the end cover, resulting in the scrapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com