Patents

Literature

44results about How to "No manual work required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

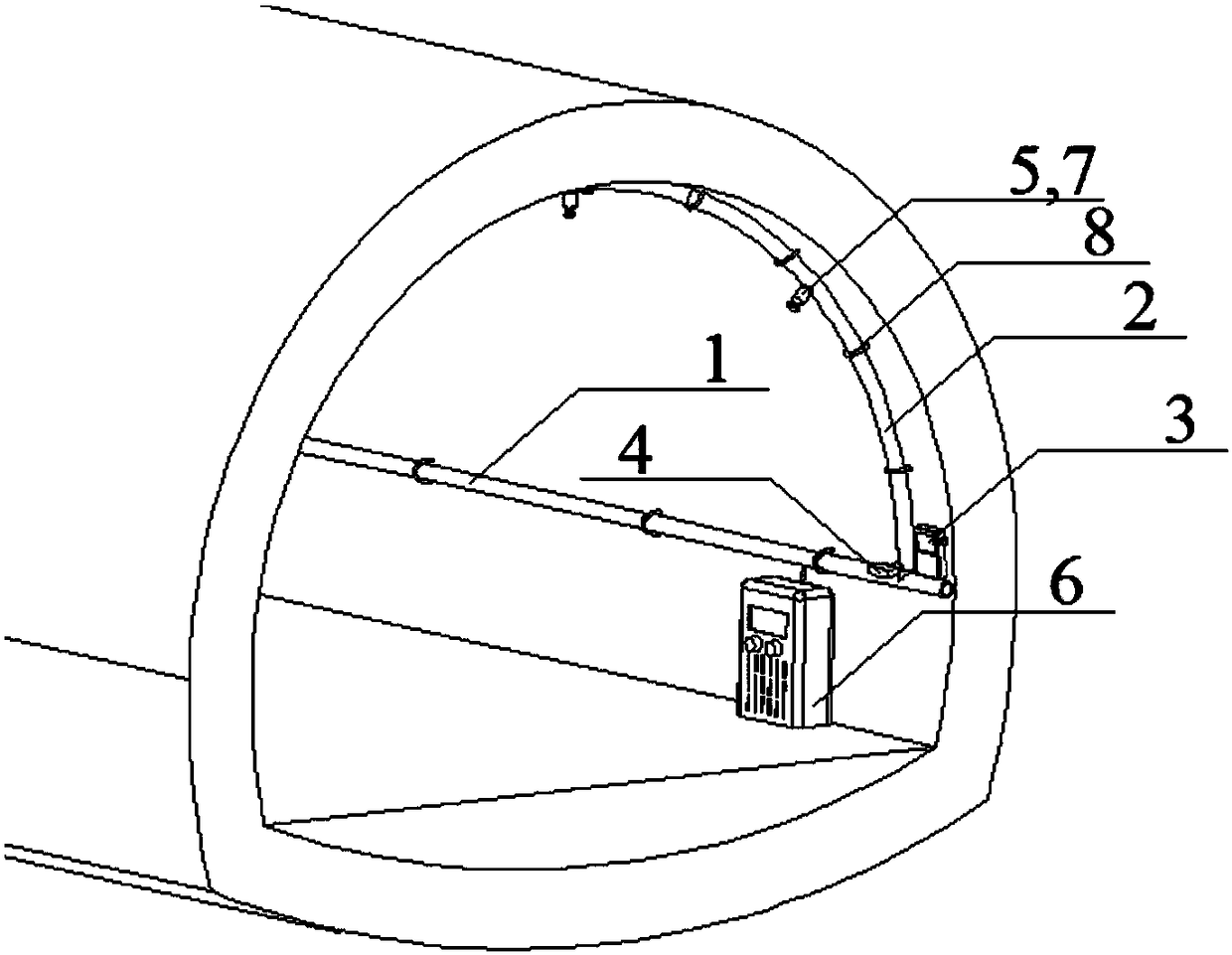

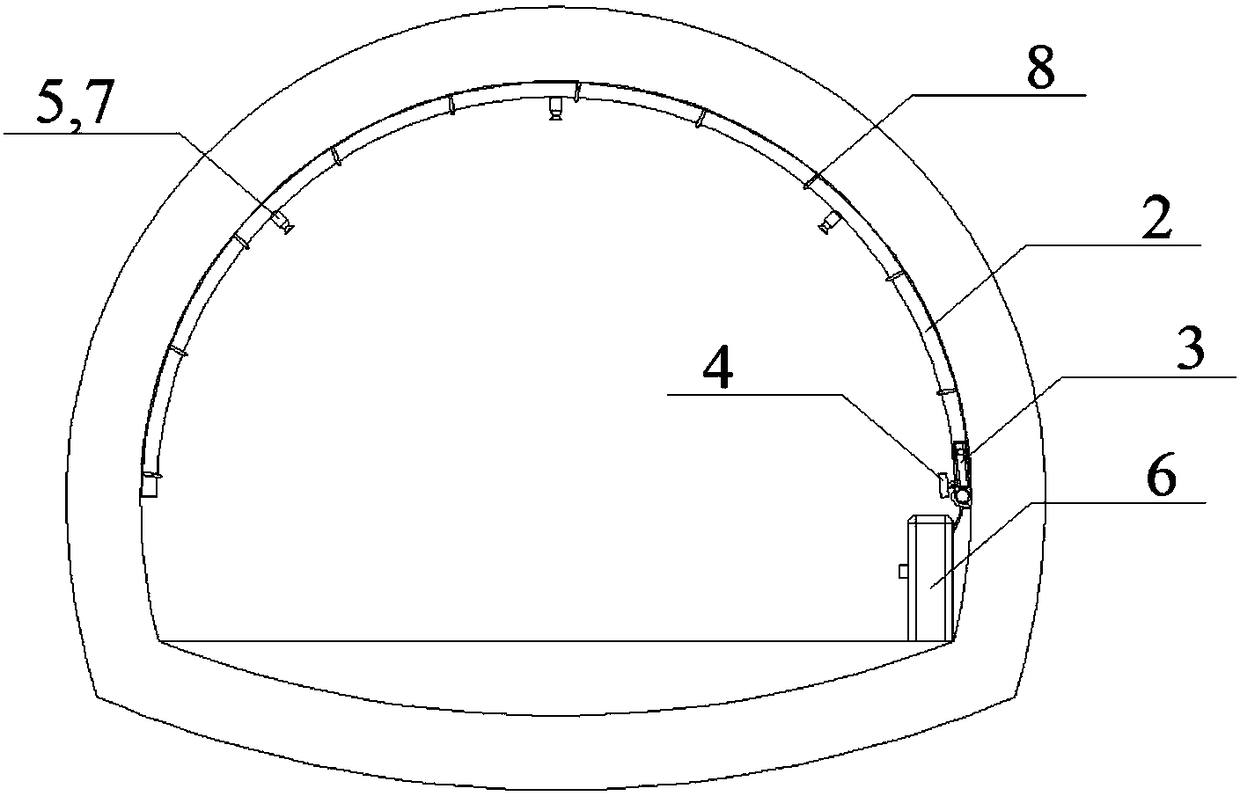

Automatic fog lowering, dedusting and cooling system and method in tunnel construction process

ActiveCN108150214AEasy to get materialsEasy to makeDust removalFire preventionPipeflowCooling effect

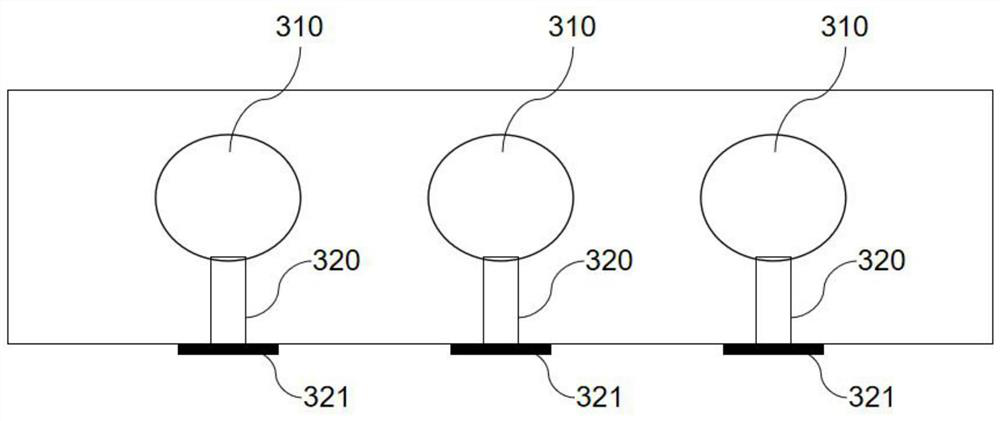

The invention discloses an automatic fog lowering, dedusting and cooling system and method in tunnel construction process. The system comprises a water guiding main pipe, water guiding pipes, a sensor, a valve, atomization devices, a cooling device, water outlets, and pipe clamps; the water guiding pipe is arranged in full profile along a tunnel vault; the pipes are fixed on the inner wall of a tunnel by the pipe clamps, and a circle of water guiding pipes are arranged every 3-5m; the water outlets of the water guiding pipes are all provided with atomization devices; the atomization devices can convert water in the water guiding pipes into an atomizing state to carry out fog lowering and dedusting, and the dedusting effect is improved; and the cooling device is arranged at an appropriate location of the water guiding main pipe, the water in the water guiding pipes is cooled and injected by the cooling device, and the cooling effect is improved. The automatic fog lowering, dedusting andcooling system and method in the tunnel construction process solve the problem of high temperature and high dust concentration in the process of tunnel construction work.

Owner:SHANDONG UNIV +1

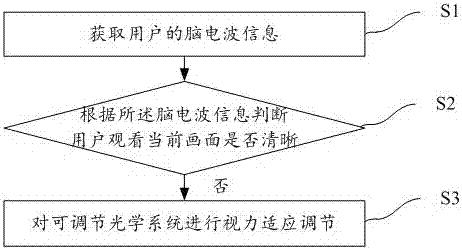

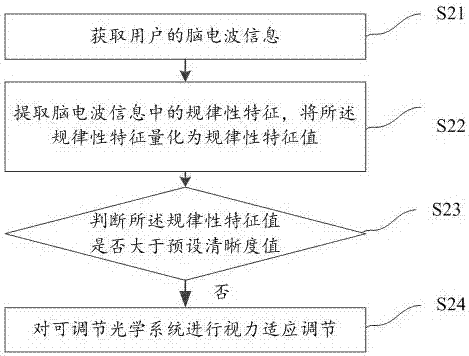

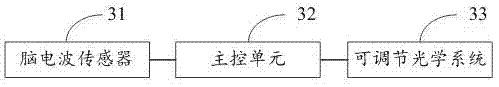

Adaptive eyesight adjusting method and system based on brain waves

ActiveCN107247513AImprove experienceNo manual work requiredInput/output for user-computer interactionGraph readingCLARITYComputer vision

The invention relates to the technical field of headset devices, in particular to an adaptive eyesight adjusting method and system based on brain waves. The adaptive eyesight adjusting method and system based on brain waves are applied to a headset device. The headset device comprises an adjustable optical system. The method comprises the following steps: acquiring brain wave information of a user; and judging whether a current picture viewed by a user is clear or not according to the brain wave information, and if the current picture viewed by the user is not clear, carrying out eyesight adaption adjustment on the adjustable optical system. Compared with the prior art, the method has the characteristics that the brain wave information of the user is acquired, the clarity of the current viewed pictures is judged through the brain wave information, therefore, the eyesight is adjusted adaptively, artificial operation is not required, the operation is simplified, and user experiences are improved.

Owner:深圳维智全息科技有限公司

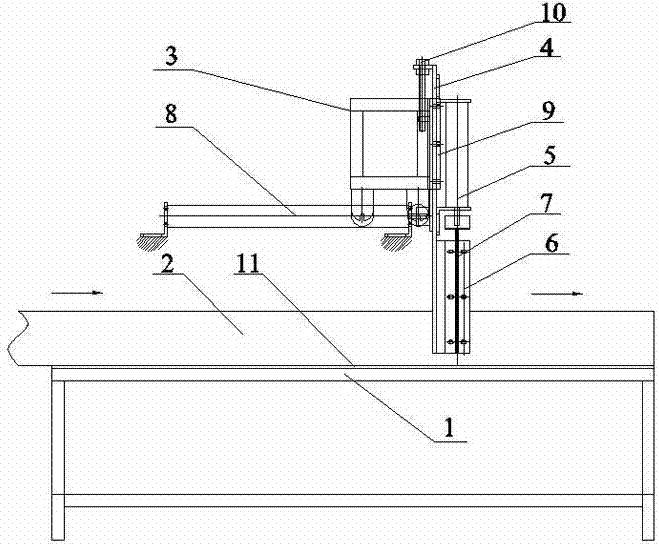

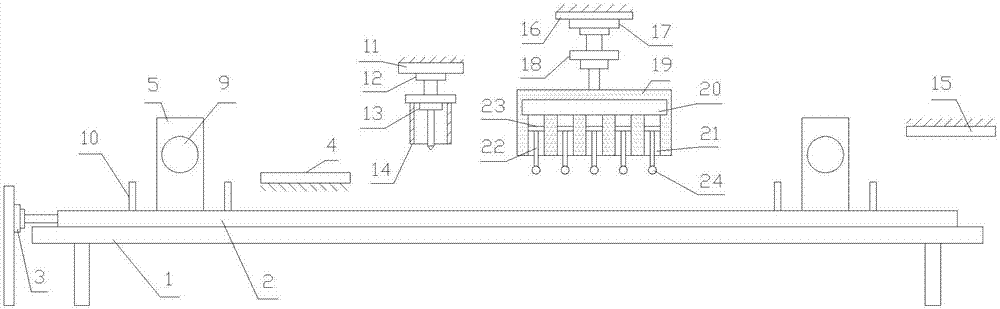

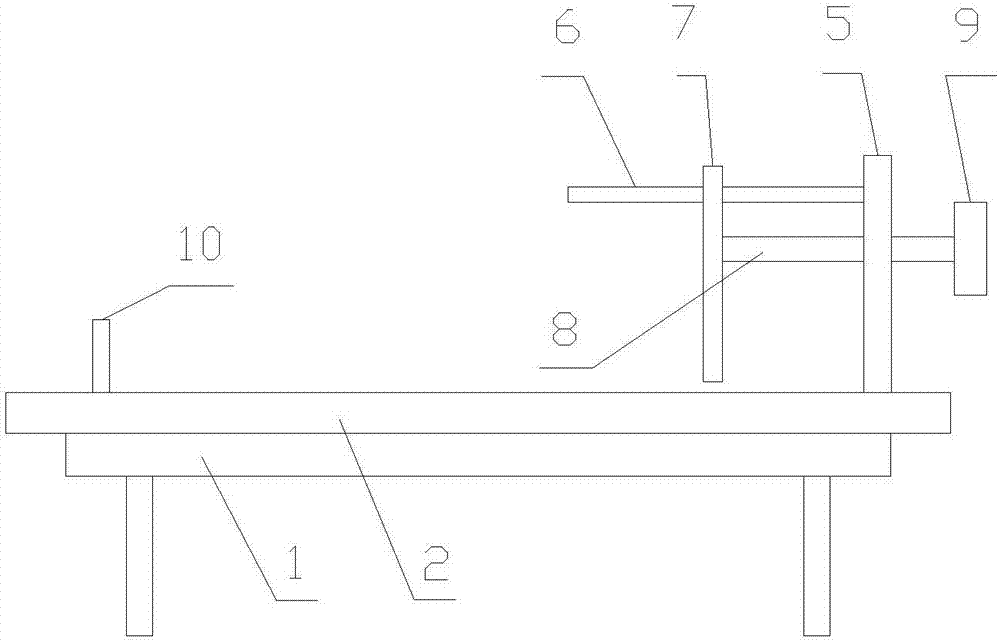

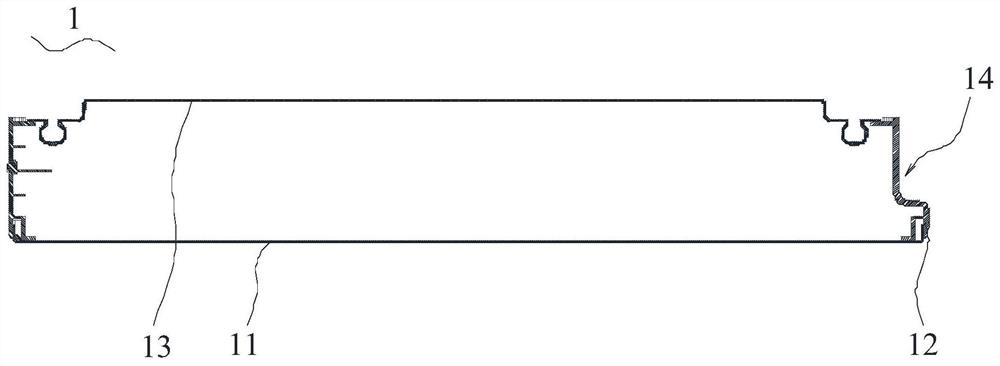

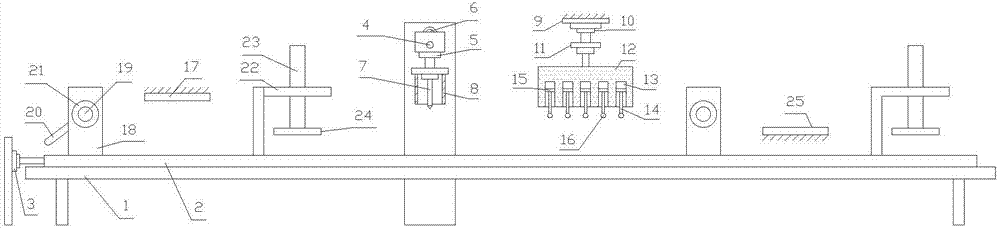

Automatic green brick cutting-off machine for producing light refractory bricks

InactiveCN104493964AImprove machining accuracyImprove processing qualityAuxillary shaping apparatusControl systemFire brick

The invention provides an automatic green brick cutting-off machine for producing light refractory bricks. The automatic green brick cutting-off machine comprises a frame, a green brick cutting-off table, a pug extruder, a pushing device, a cutting-off device and a PLC control system; the green brick cutting-off machine is capable of stably and reliable cutting off strip-shaped pug bars extruded by the pug extruder into green bricks of the specified size due to the arrangement of such mechanisms as a sensor, the green brick pushing device, the cutting-off device and the PLC control system. The automatic green brick cutting-off machine is high in overall automation degree, convenient for production without manual work, and especially suitable for producing the semi-finished products of the light refractory bricks; as a result, the working efficiency is improved, the labor intensity is reduced, and the production precision of the green bricks and the product quality also are improved; the automatic green brick cutting-off machine is suitable for popularization and application.

Owner:平顶山新型耐材股份有限公司

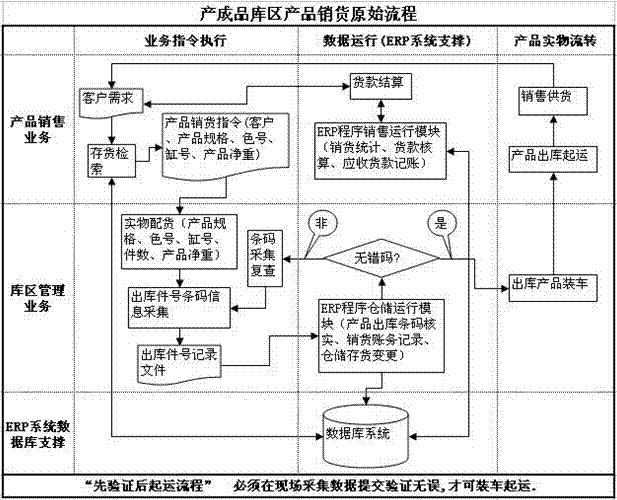

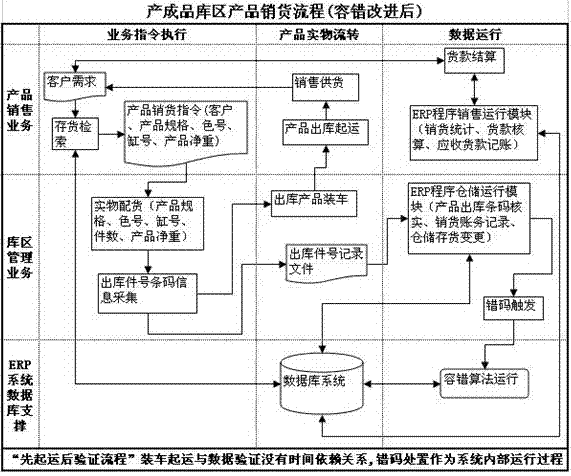

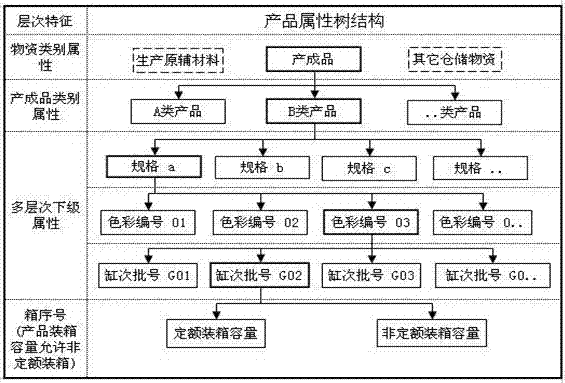

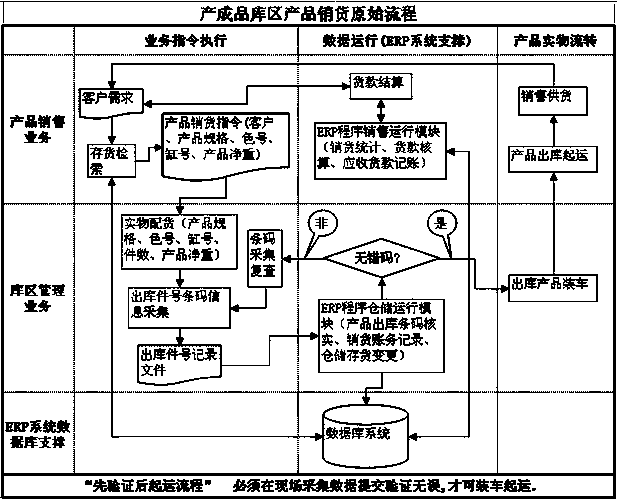

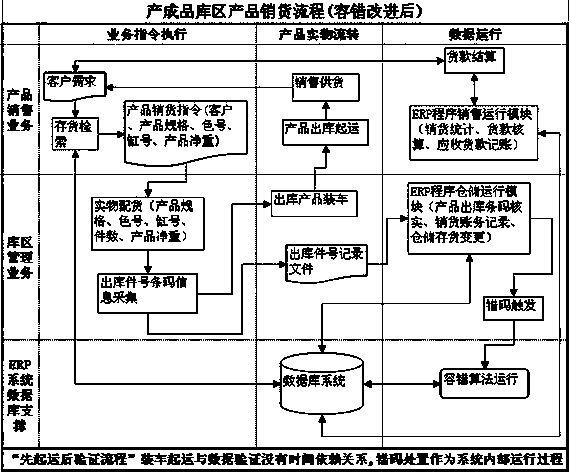

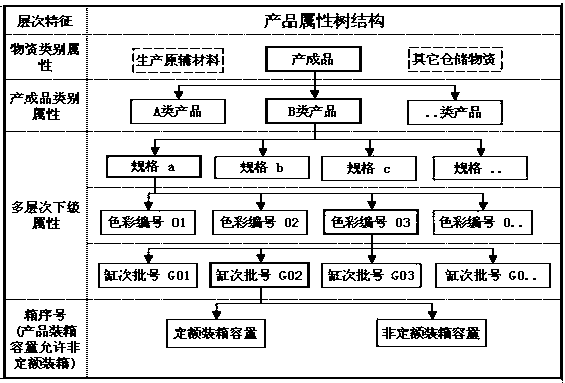

Error tolerance and correction method for analysis of bar code identifiers of storage materials

ActiveCN102509200AImprove objectivityNo manual work requiredLogisticsSensing by electromagnetic radiationError toleranceStorage material

The invention relates to the field of the management of storage materials, in particular to an error tolerance and correction method for analysis of bar code identifiers of the storage materials. The method comprises the following steps of: (1) acquiring bar code data of the storage materials on site; (2) loading and transporting the storage materials which are subjected to data acquisition; (3) carrying out data interpretation authentication on the bar code data acquired in the step (1) by the existent ERP (Enterprise Resource Planning) program; and (4) calling an embedded module to carry out error tolerance and correction treatment on information which is interpreted to be wrong in the step (3). The error tolerance and correction method for the analysis of the bar code identifiers of the storage materials has the advantages that: warehouse-out data of the storage materials can be finished acquiring and behindhand verifying in an off-line manner without geographical restrictions; the method is a method in which error code iterative computation is automatically called, a true code number corresponding to an original error code is restored after carrying out finite number of iterations, and the automatic error correction is finished without manual intervention; and for the iterative computation, the operation of module calling and data result returning is automatically finished inside the program without the manual operation of operators.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

Integrated automatic monitoring device for deep displacement and surface displacement and method

InactiveCN110006382AAccurate and Effective MonitoringAccurate and effective all-round monitoringIncline measurementEngineeringTest object

The invention relates to the technical field of geological disaster monitoring, and discloses an integrated automatic monitoring device for deep displacement and surface displacement and a method. Thedevice comprises a multi-constellation satellite positioning system and an array type flexible inclinometer, wherein the array type flexible inclinometer is pressed through a press device and then isinstalled in an inclinometer casing, the multi-constellation satellite positioning system is fixedly installed above the press device, and the array type flexible inclinometer is connected with the multi-constellation satellite positioning system. According to the integrated automatic monitoring device for deep displacement and surface displacement, angle of inclination of a tested object can bededuced through angle of inclination of a steep pipe, the integrated automatic monitoring device takes on a 3D installation structure overall, thereby being not limited by the space and monitoring deep displacement accurately and effectively. The device can monitor automatically, requires no manual work, has high accuracy, and is highly reliable, thereby being widely used in occasions like side slopes, mountains and dams.

Owner:华思(广州)测控科技有限公司

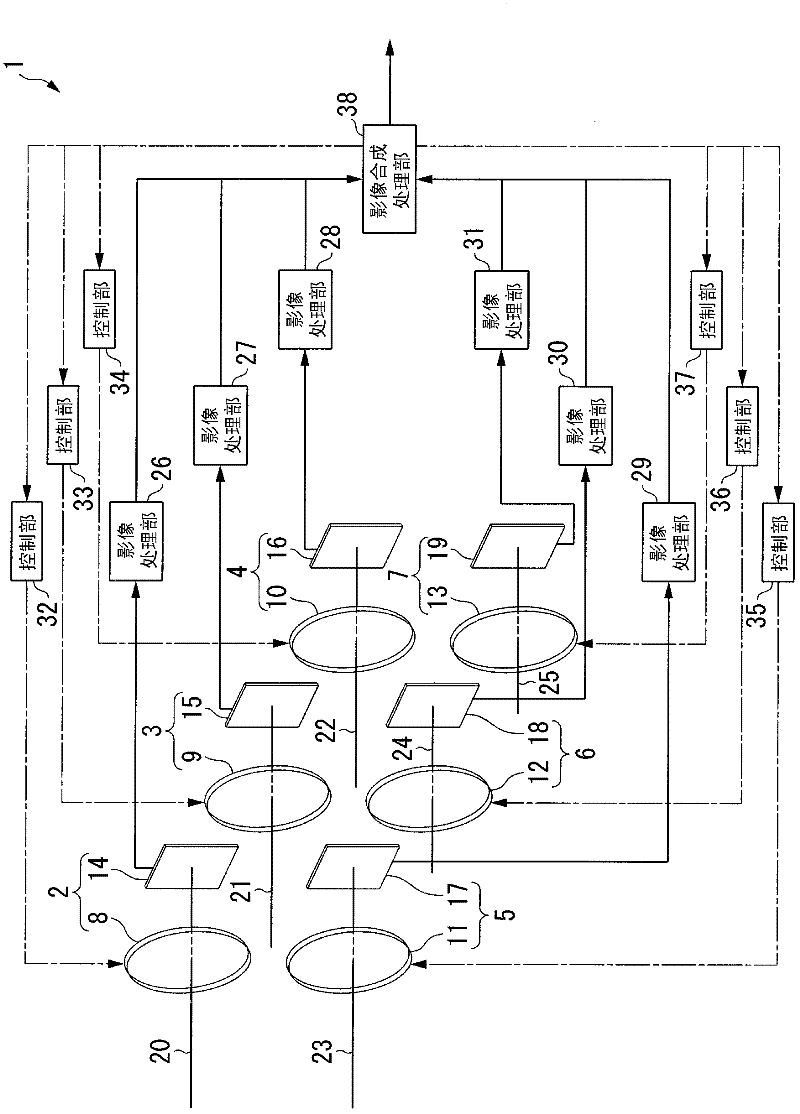

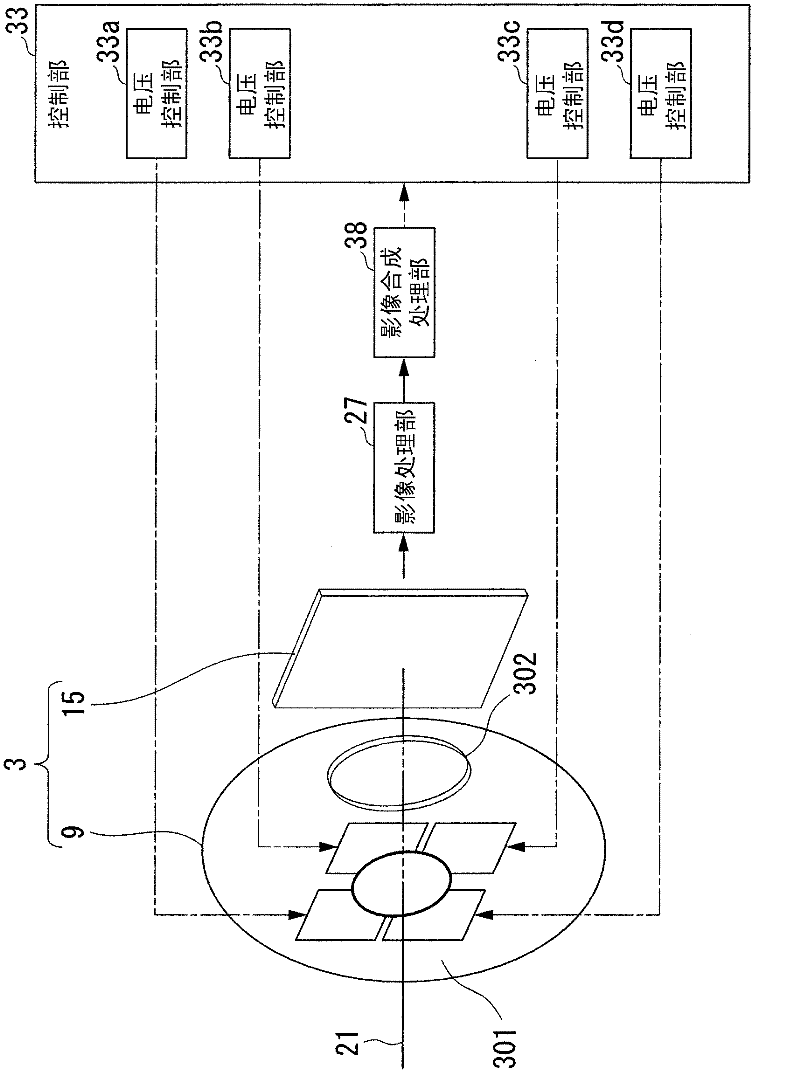

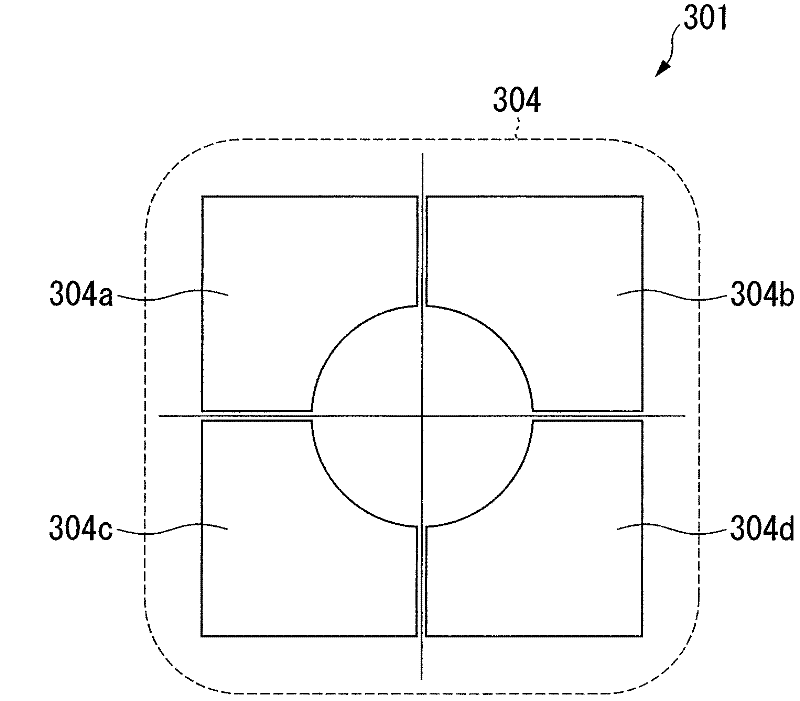

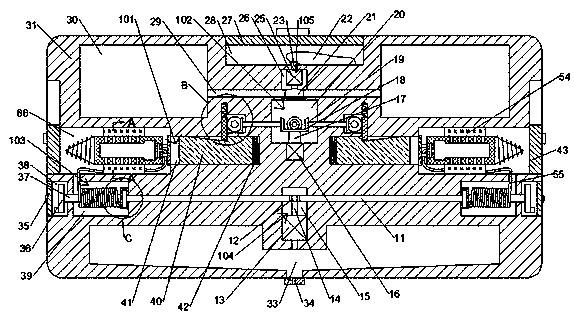

Imaging apparatus and imaging method

InactiveCN102365859AEasy to adjustImprove picture qualityTelevision system detailsGeometric image transformationStereo matchingImaging processing

An imaging apparatus provided with: a plurality of imaging elements; a plurality of solid lenses which form images on the plurality of imaging elements; a plurality of optical axis control units which control the directions of the optical axes of the light beams incident on the plurality of imaging elements; a plurality of video processing units which convert the photoelectric converted signals output by the plurality of imaging elements into video signals; a stereo image processing unit which, based on the plurality of video signals converted by the plurality of video processing units, carries out stereo matching processing to find the shift amount for each pixel, and generates compositing parameters in which the shift amounts exceeding the pixel pitch of the plurality of imaging elements are normalized by the pixel pitch; and a video compositing processing unit which combines the video signals converted by each of the plurality of video processing units based on the compositing parameters generated by the stereo image processing unit, and thereby generates high definition video.

Owner:SHARP KK

Water quality monitoring and collecting device with discrete collecting function

ActiveCN110426243AInhibit sheddingNo manual work requiredWithdrawing sample devicesWater qualityEngineering

The invention discloses a water quality monitoring and collecting device with a discrete collecting function. The water quality monitoring and collecting device comprises a main unit body. Four shooting cavities in central symmetry are arranged in the main unit body. Soft clamping blocks are fixedly installed on the upper wall and the lower wall of each shooting cavity respectively, and a collecting body capable for shooting and collecting a water sample at the water bottom is clamped between the two corresponding soft clamping blocks. The central symmetry sides of the four shooting cavities are all communicated with a hitting cavity. A hitting block is slidingly arranged on the inner wall of the hitting cavity. A control mechanism which can control the hitting block to be ejected out towards the transmission cavities and hit the collecting bodies to be shot into water is arranged in the hitting cavity. By shooting the four hitting blocks in different directions to collect the water samples at different positions in water, the water quality monitoring data result is higher in reliability and representativeness; when the samples are obtained, the water quality monitoring and collecting device can be directly out in water; the water quality monitoring and collecting device can automatically float up to the water surface when recovered, operation can be conducted without consuminggreat labor, and troubles and labor are saved.

Owner:山东纵横德智环境咨询有限公司

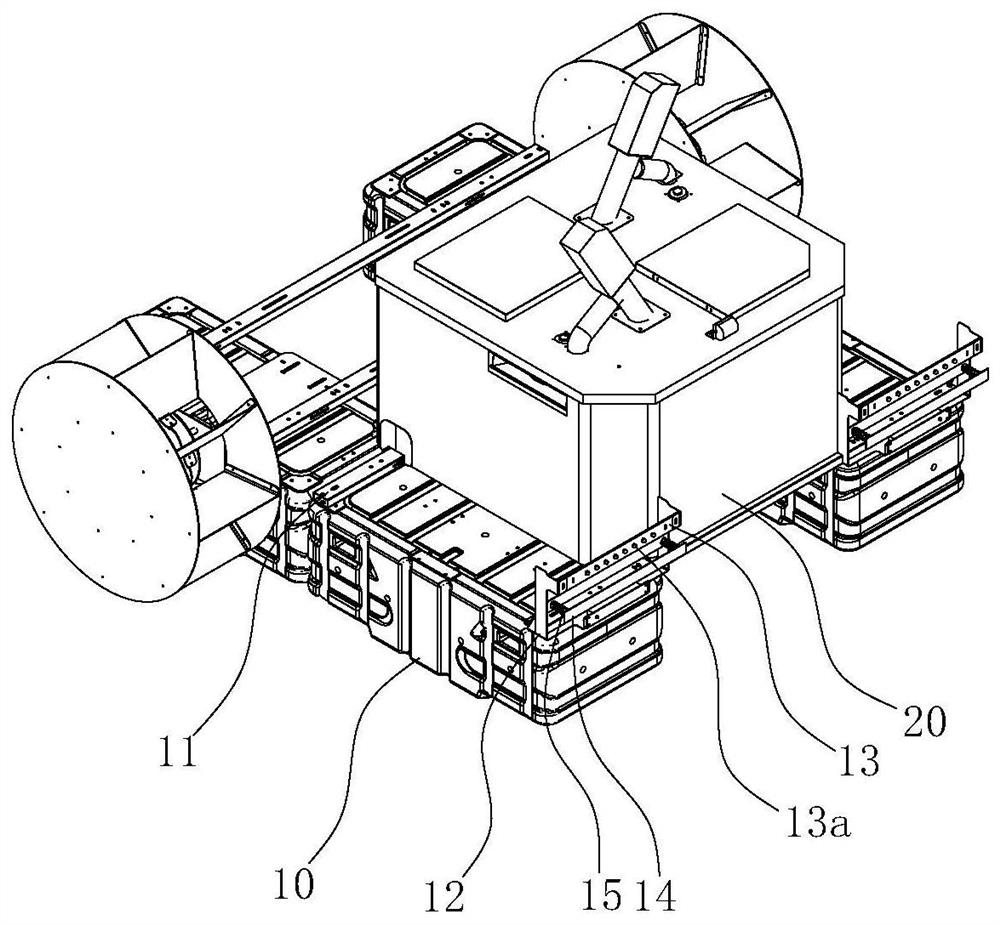

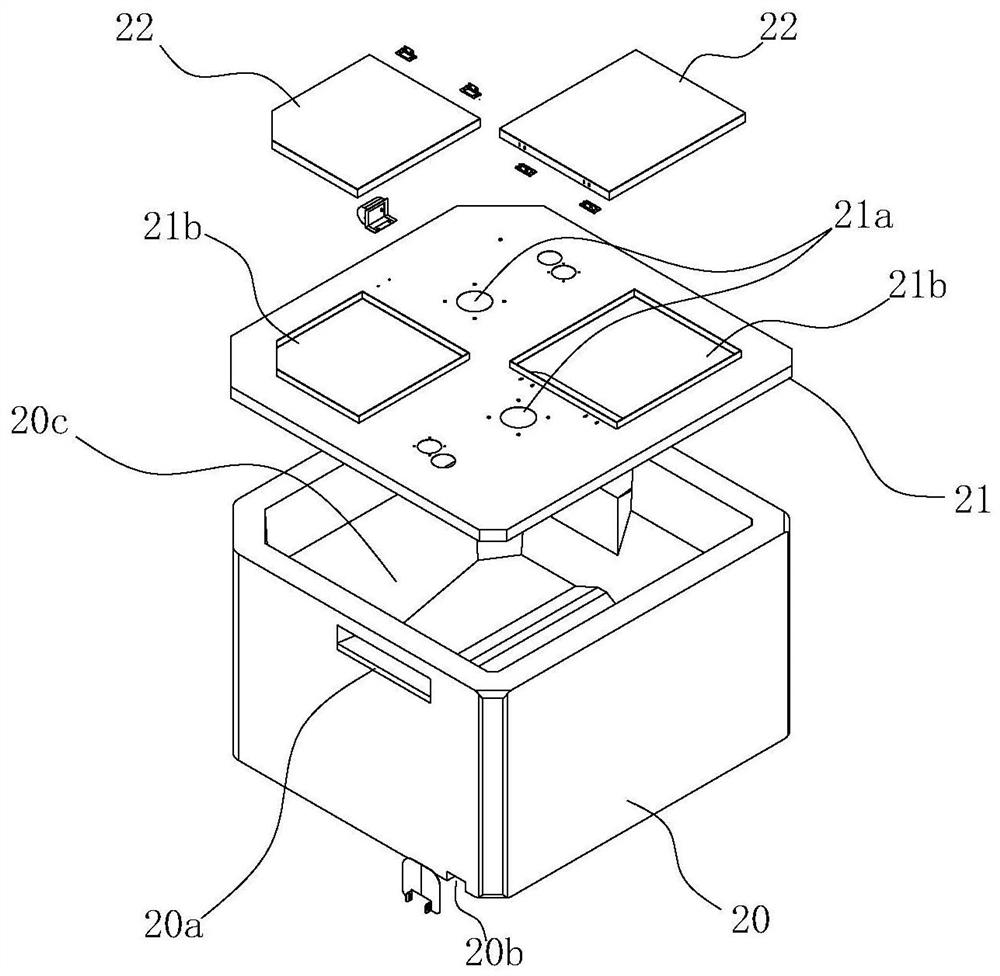

Floating type unmanned bait casting boat

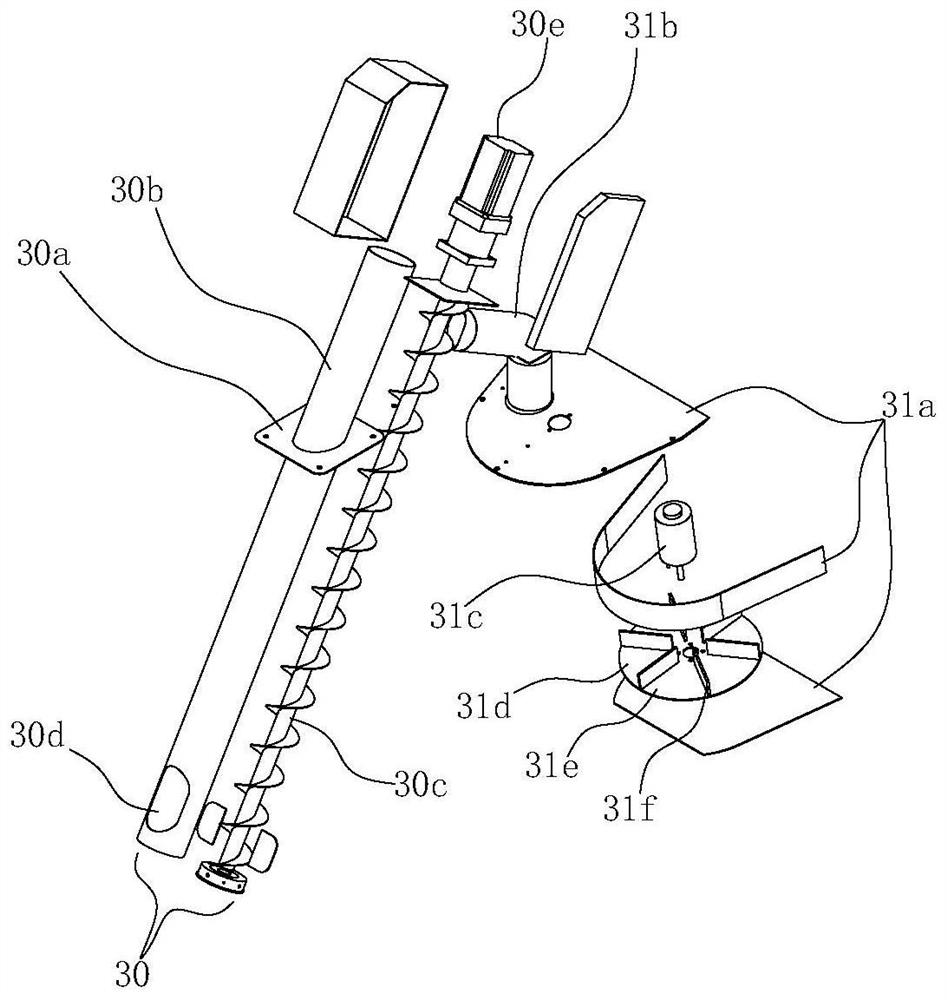

PendingCN113060248ADrive stabilityEasy to cooperate with the dock to realize automatic chargingCharging stationsClimate change adaptationStructural engineeringFishing

The invention belongs to the technical field of fishery automatic production equipment, and particularly relates to a floating type unmanned bait casting boat. The boat comprises a hull assembly, a cabin assembly and a material throwing assembly; the hull assembly comprises two floating body structures, a supporting structure connected with the two floating body structures and a charging structure arranged on the rear sides of the floating body structures, and the cabin assembly comprises a material bin detachably connected with a supporting frame; the material throwing assembly comprises a feeding device arranged in a mounting opening and a material throwing device arranged on the inner side of a material throwing opening. The floating type unmanned bait casting boat is light and compact in mechanism, paddle wheel driving is stable, automatic charging can be conveniently achieved in cooperation with a dock through the self-contained charging device so that continuous operation can be conducted, a bait throwing device can evenly form an operation area on the water surface, the efficiency of operation such as feeding in a fishing ground can be effectively improved, manual operation is not needed, and the production cost is reduced.

Owner:国网江苏省电力有限公司兴化市供电分公司 +2

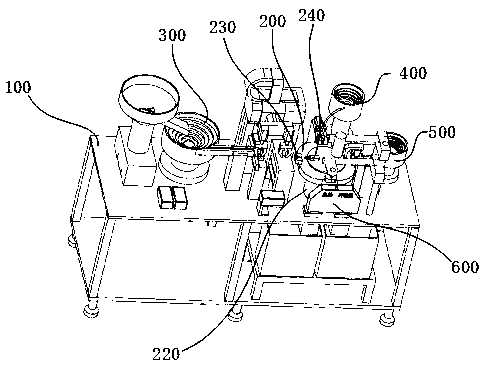

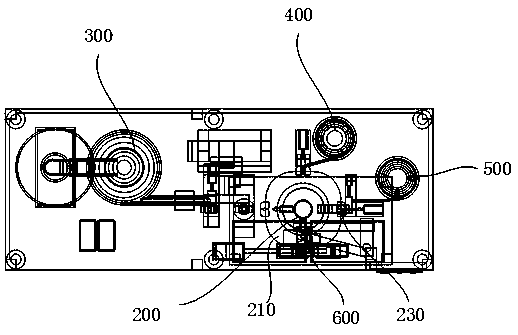

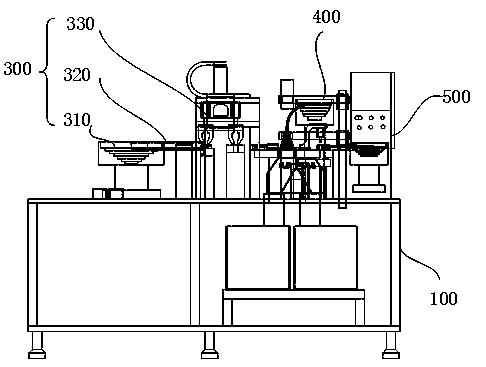

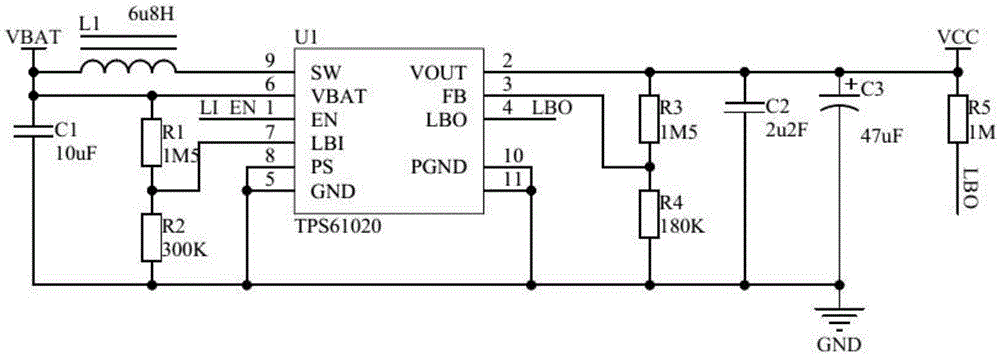

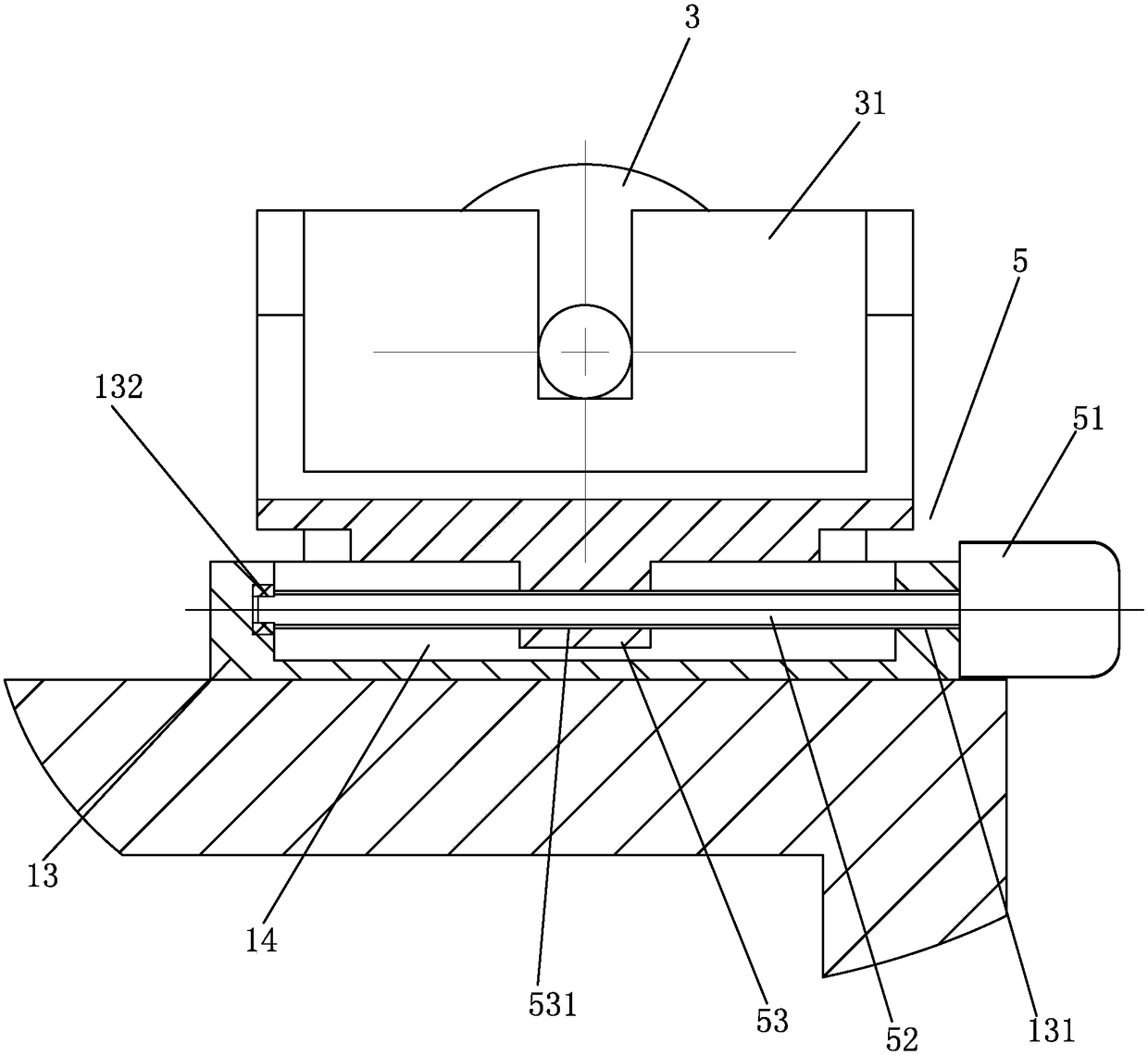

One-way valve automatic assembly apparatus

PendingCN110961914AImprove the quality ratio of finished productsNo manual work requiredAssembly machinesEngineeringMechanical engineering

The present application discloses a one-way valve automatic assembly apparatus, including: a frame and a group consisting of an index plate transfer unit, a valve body assembly unit, a ball assembly unit, a pin assembly unit and a sorting unit which are disposed on the frame; the index plate transfer unit is configured to assemble a one-way valve; the valve body assembly unit is configured to transfer the valve body to the index plate transfer unit; the ball assembly unit is configured to transfer a ball to the index plate transfer unit; the pin assembly unit is configured to transfer a pin part to the index plate transfer unit; the sorting unit is configured to receive and determine whether a finished one-way valve product is a qualified product; the index plate transfer unit is rotatable; and the valve body assembly unit, the ball assembly unit, the pin assembly unit, and the sorting unit sequentially transfer the valve body, the ball, and the pin part to the index plate transfer unit along the rotation direction of the index plate transfer unit in order to assemble the valve body, the ball, and the pin part into a one-way valve; and finally the sorting unit sorts the one-way valve.

Owner:上海易扣精密件制造有限公司

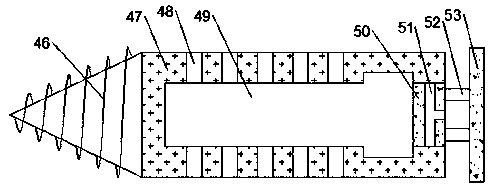

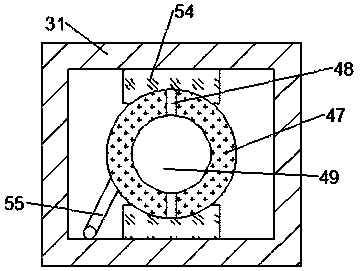

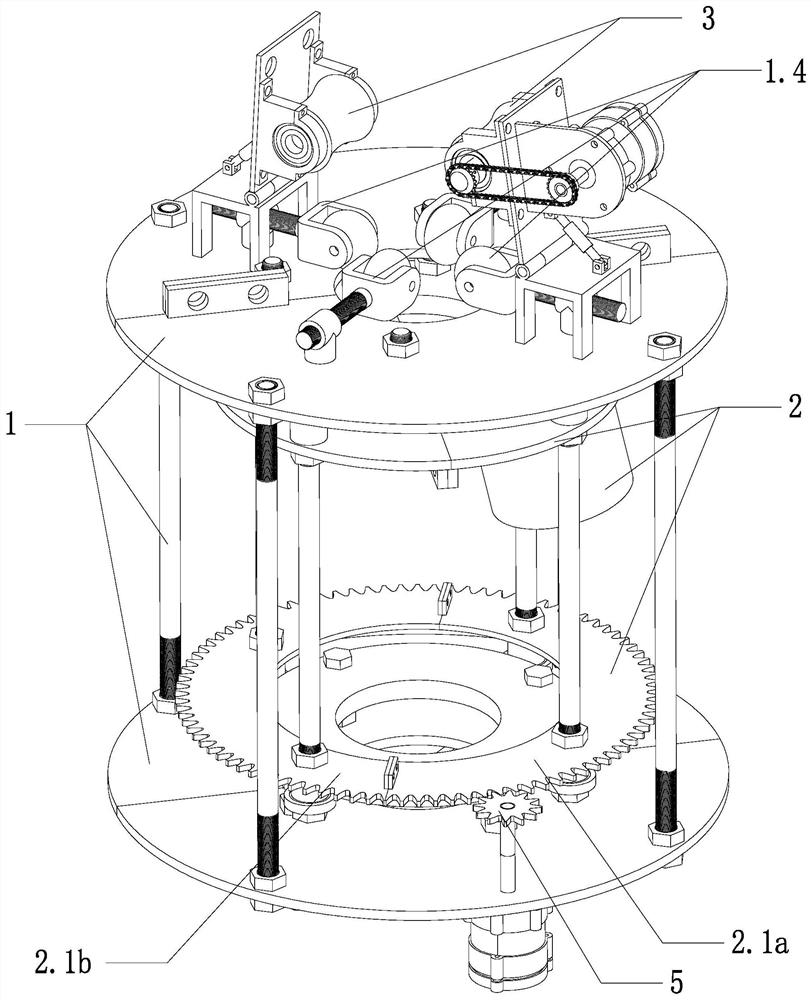

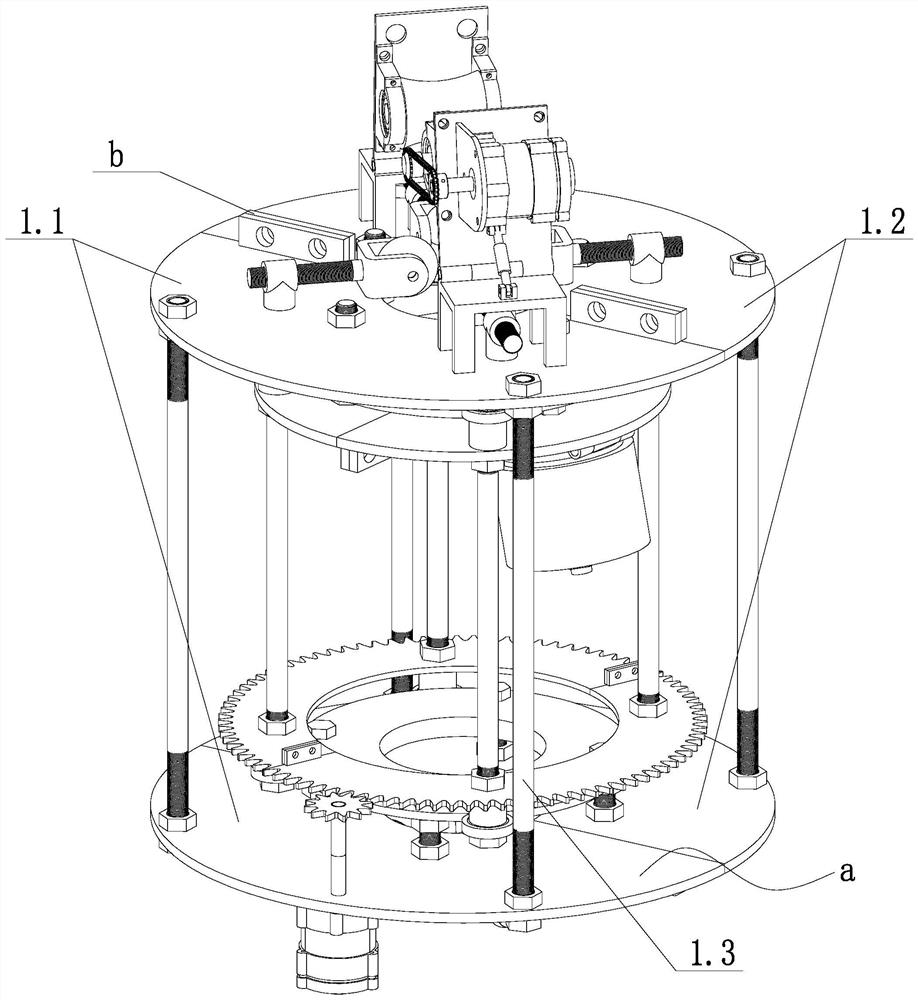

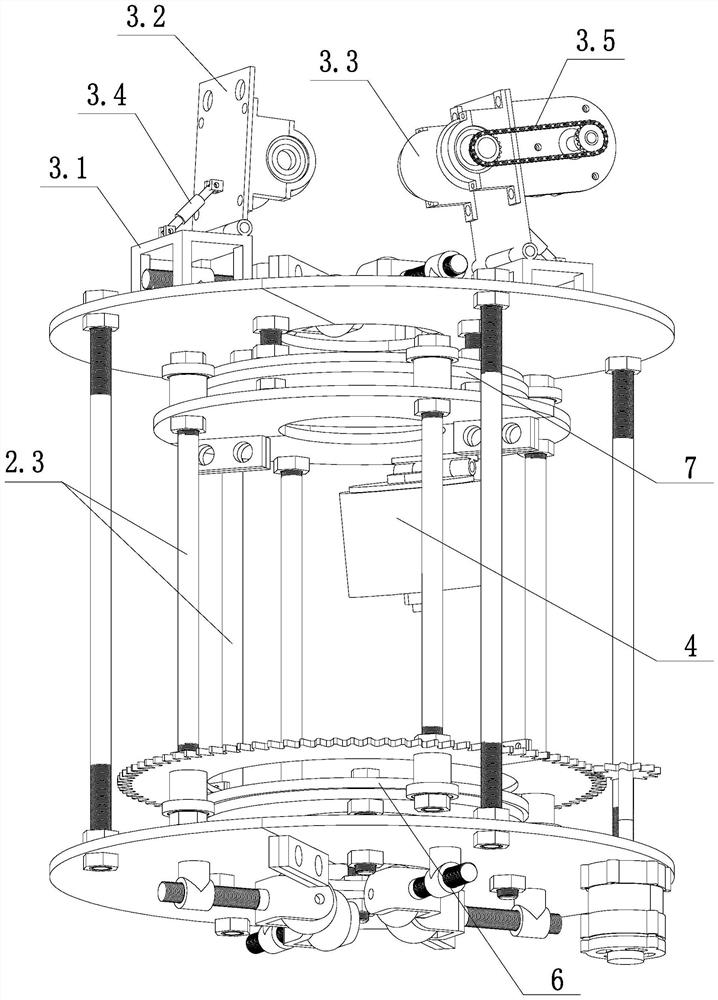

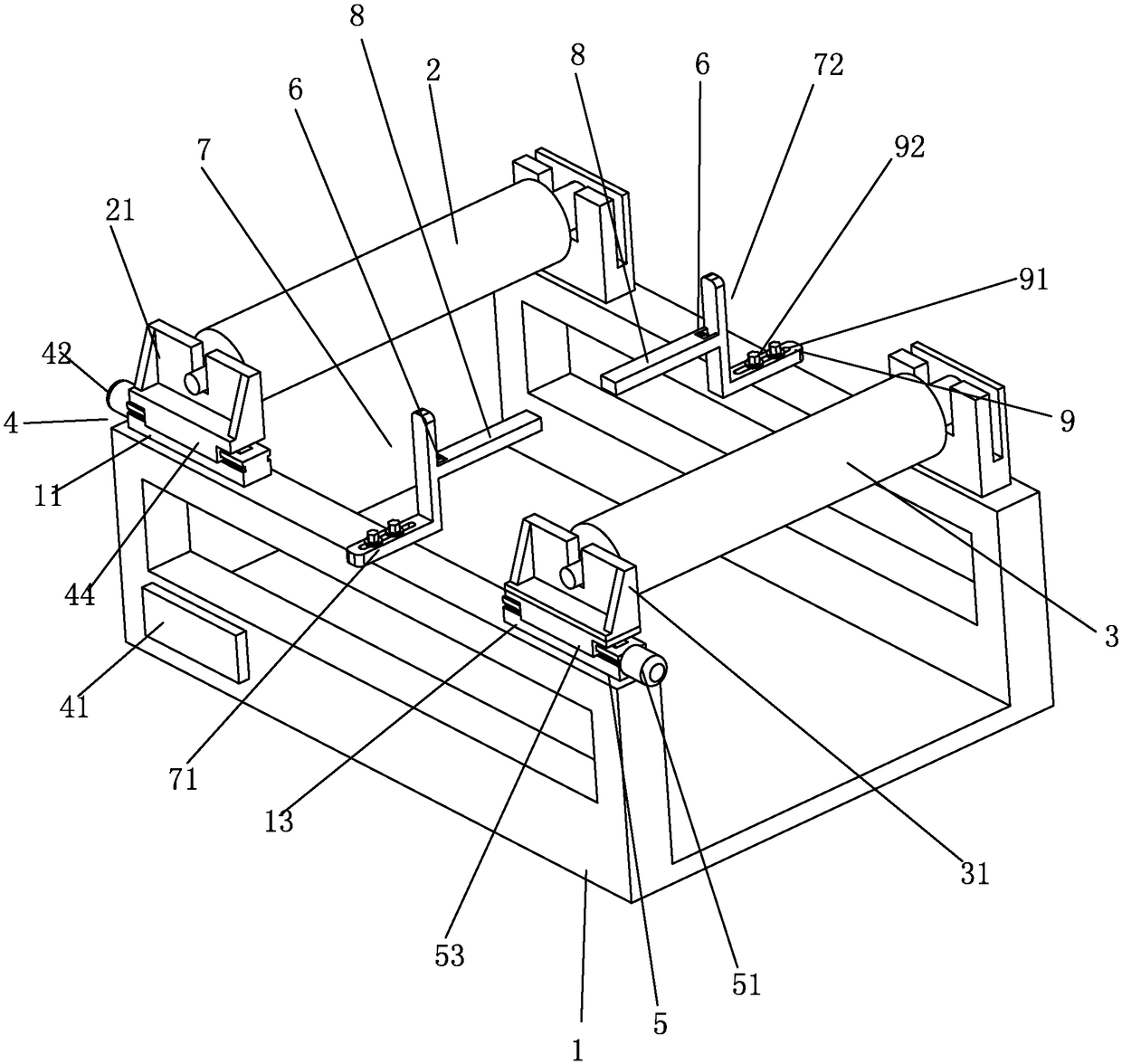

Pipe film coating machine and method of use thereof

PendingCN111775439AHeight adjustableRealize the secondary coating actionFilm-coated tabletFilm coating

The invention discloses a pipe film coating machine and a method of use thereof. The pipe film coating machine comprises a pipe clamping mechanism, a film coil winding mechanism and a pushing mechanism, wherein the pipe clamping mechanism is of a half-divided structure; the film coil winding mechanism is arranged at the inner side of the pipe clamping mechanism, and a moving mechanism is arrangedat the outer side of one end of the pipe clamping mechanism; the pipe clamping mechanism comprises first support plates and second support plates, the two first support plates are respectively distributed on one side in the axial direction, and the two second support plates are respectively distributed on the other side in the axial direction; the support plates on the same side are connected by afirst positioning bolt extending axially, and the first support plates and the second support plates that are assembled with each other are fixed and assembled by mounting plates; and the pipe clamping mechanism also comprises a pipe pressing mechanism on the outer sides of the complete support plates, the pipe pressing mechanism comprises at least two pressing wheels distributed along the circumference of the complete support plates, and the pressing wheels can extend and contract in the radial direction of the support plates to realize the compaction on a pipe. The pipe film coating machinehas the advantages of not requiring manual direct operation, and having high efficiency and low cost.

Owner:新疆新鲁博科技有限公司 +1

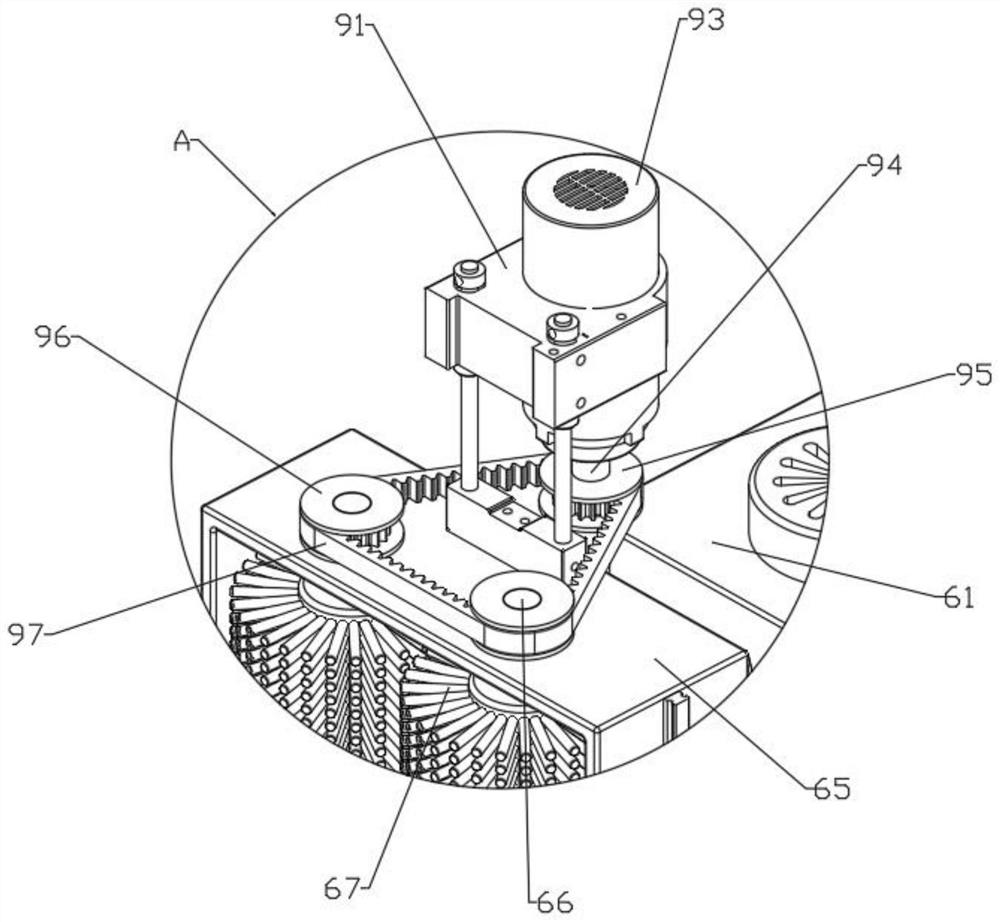

Automatic USB plug assembly BOOT automatic machine

The invention discloses an automatic USB plug assembly BOOT automatic machine which comprises a USB carrier positioning and pressing assembly, a BOOT assembling assembly, a wire USB carrier assembly and a USB guiding assembly. The USB carrier positioning and pressing assembly, the wire USB carrier assembly and the USB guiding assembly are fixedly arranged on a workbench separately. The BOOT assembling assembly is fixedly arranged on the USB carrier positioning and pressing assembly. The automatic USB plug assembly BOOT automatic machine has the advantages that no manual operation is needed, operation is quite convenient, the machine operation speed is high, motions are smooth, the production efficiency is quite high, precise product positioning is achieved, it can be ensured that every peeling position is at the same position, the production precision can meet the requirement, USB clamping assembly is driven by a gear rack to be operated, the assembly is long in service life and littlein abrasion, and the machine using period is long.

Owner:CHANGDE FUBO INTELLIGENCE TECH CO LTD

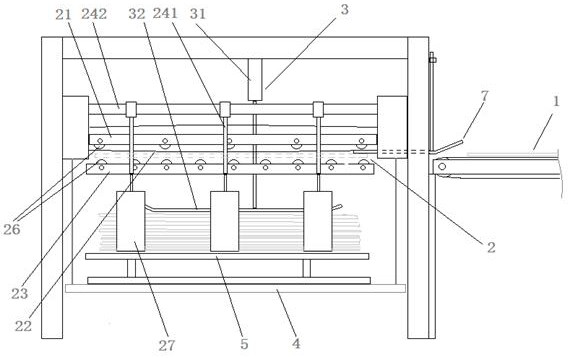

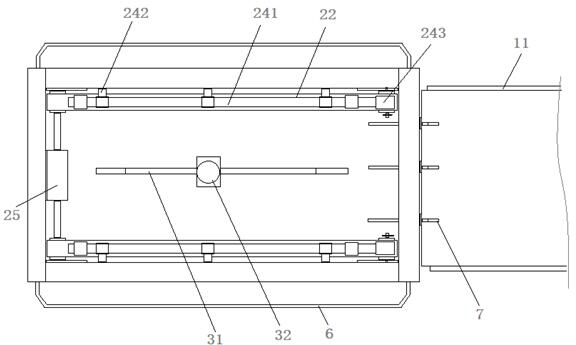

Wood chip automatic stacking machine

PendingCN111731855ANo manual work requiredThin and easy to bendConveyorsStacking articlesProduction lineStructural engineering

The invention discloses a wood chip automatic stacking machine. The device comprises a material conveying channel located at a high position and a stacking device arranged behind the material conveying channel, the stacking device comprises edge pressing clamping channels and a plate pressing mechanism mounted which are mounted on a rack, the edge pressing clamping channels are same to a materialdischarging direction of the material conveying channel, and are installed in a left-right symmetric mode, spacing is smaller than a width of a to-be-stacked wood chip, the edge pressing clamping channels and the material conveying channel are equal in height, the edge pressing clamping channels comprise upper clamping pieces, conveying belts, lower supporting pieces and lower supporting piece driving mechanisms, the conveying belts are wrapped around the upper clamping pieces and are driven to rotate in a material conveying direction of the edge pressing clamping channels, the lower supporting piece driving mechanisms are connected with the lower supporting pieces, the lower supporting pieces are driven to shift and move below the conveying belts and the outer side edges of the conveyingbelts, the plate pressing mechanism comprises a pressing rod and a telescopic cylinder, the pressing rod is located above the horizontal position between the two edge pressing clamping channels, the pressing rod is connected with a telescopic rod of the telescopic cylinder, and the telescopic rod pushes the pressing rod to run up and down. The effect of automatically stacking thin wood chips is achieved, labor is saved, efficiency is high, and front and rear connection of production line capacity is improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

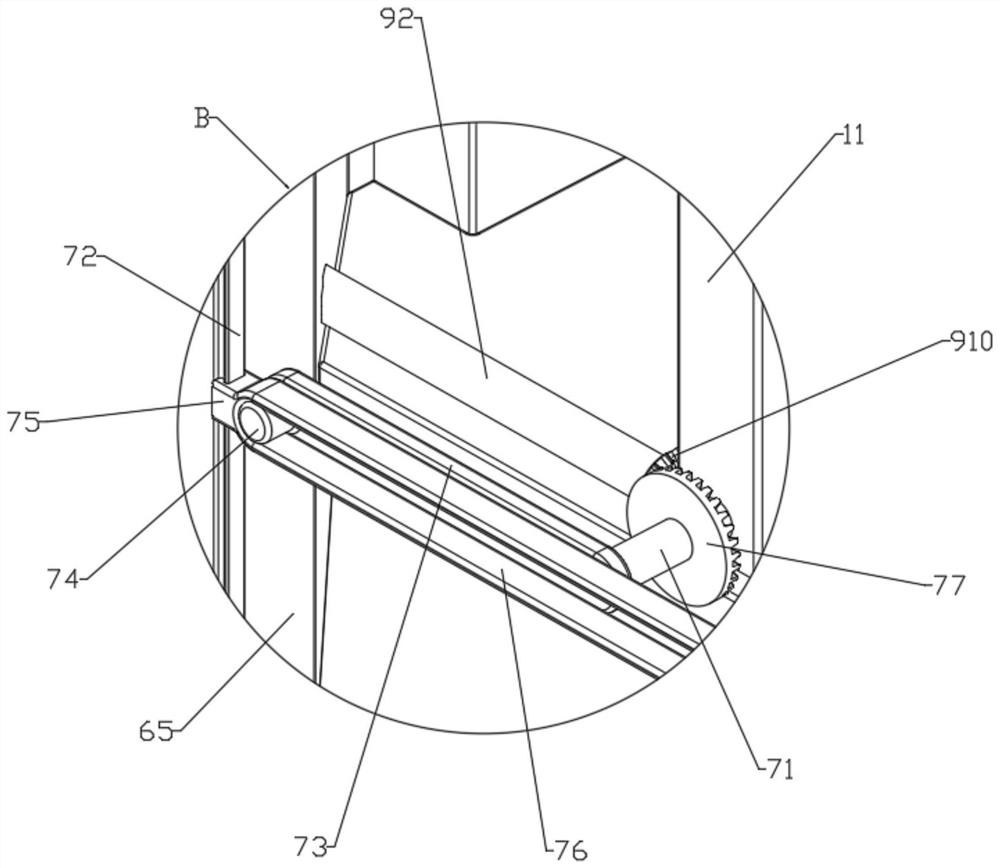

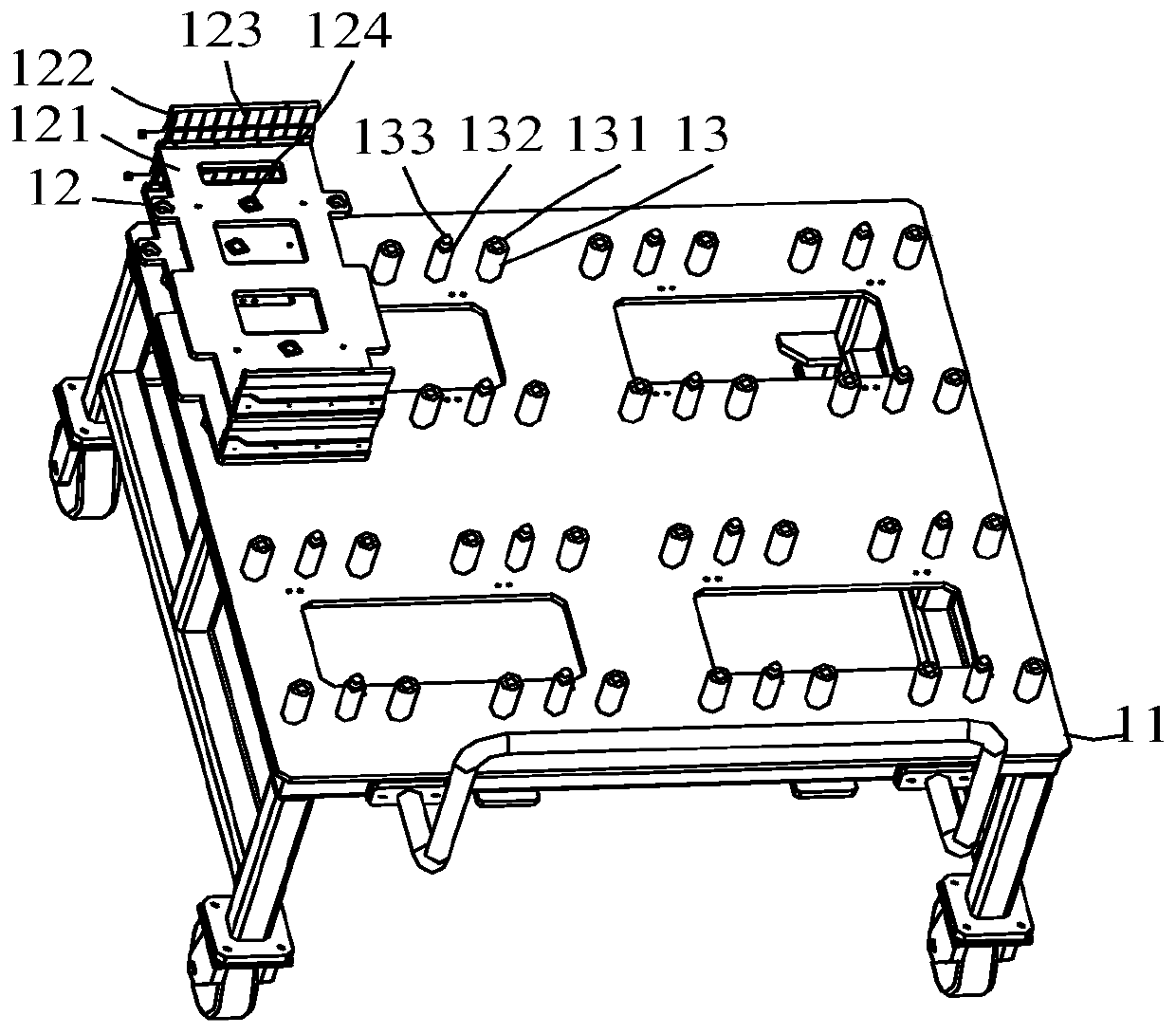

Continuous production line for power supply box

ActiveCN107470797ANo manual work requiredPressing and fixing with high precisionWelding/cutting auxillary devicesAuxillary welding devicesSheet steelManufacturing line

The invention discloses a continuous production line for a power supply box. The continuous production line for the power supply box is used for welding of a steel plate and at least comprises a supporting table, a supporting plate, a power mechanism, a press-holding part and a welding part. The supporting plate is slidably connected with the supporting table; the power mechanism is used for driving the supporting plate to move in the length direction of the supporting table; the press-holding part comprises a plurality of press-holding mechanisms and a first rack; the multiple press-holding mechanisms are distributed sequentially in the length direction of the supporting table; each press-holding mechanism comprises a first press-holding unit and a second press-holding unit, wherein the first press-holding unit and the second press-holding unit are distributed oppositely in the length direction perpendicular to the supporting table; the first press-holding units comprise mounting plates, sliding rods, press-holding plates, screws and gears; the mounting plates are mounted on the supporting plates, and thread holes are formed in the mounting plates; and the sliding rods are connected with the mounting plates and arranged horizontally, and the length direction of the sliding rods is perpendicular to the length direction of the supporting table.

Owner:芜湖锐华暖通科技股份有限公司

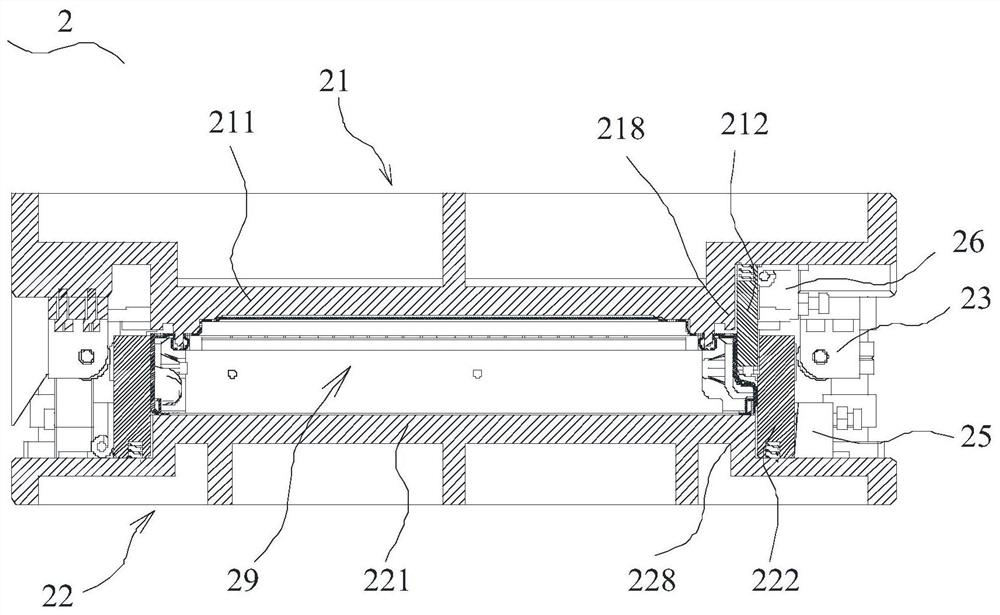

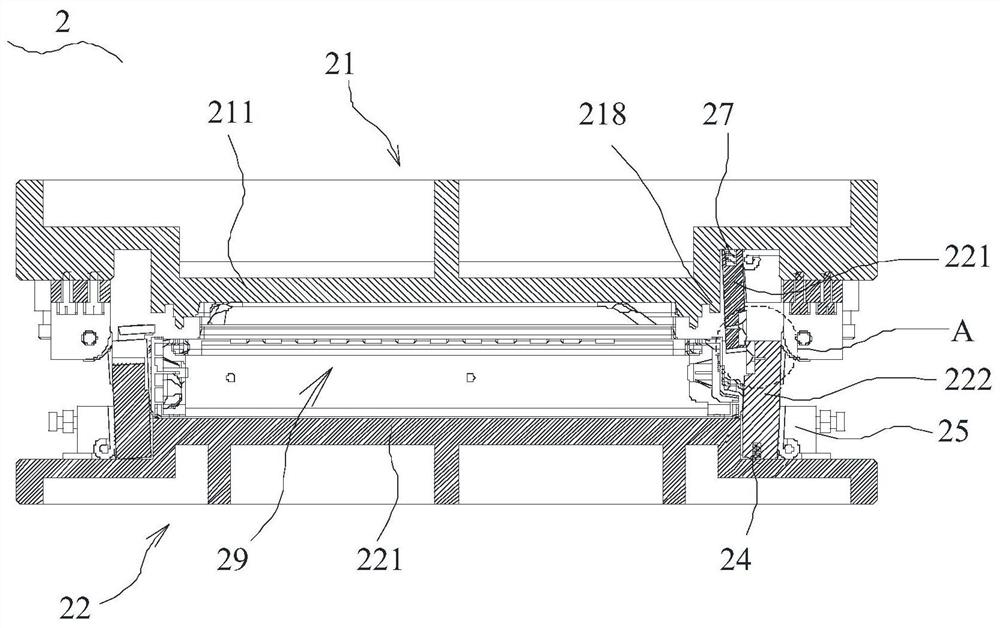

Foaming mold of refrigerator door body

InactiveCN111673975AGuaranteed accuracyImprove yieldDomestic articlesEngineeringMechanical engineering

The invention relates to a foaming mold of a refrigerator door body. The foaming mold comprises an upper mold assembly and a lower mold assembly; the upper mold assembly comprises an upper mold base,an upper movable barrier strip and a guide piece, wherein an upper mold cavity with a bottom opening is defined by the upper mold base and the upper movable barrier strip; the lower mold assembly comprises a lower mold base and a lower movable barrier strip, wherein a lower mold cavity with an upper opening is defined by the lower mold base and the lower movable barrier strip; and when the upper mold cavity and the lower mold cavity perform mold closing, the upper movable barrier strip extends into the inner side of the lower movable barrier strip, the lower movable barrier strip extends intoa gap between the guide piece and the upper movable barrier strip and is extruded by the guide piece, so that the lower movable barrier strip drives the upper movable barrier strip to rotate inwards together. According to the foaming mold, the upper movable barrier strip abuts against the side wall of a step of an end cover, the lower movable barrier strip abuts against the lower portion of the end cover, the end cover, a door shell and a door inner container are accurately positioned through the upper movable barrier strip and the lower movable barrier strip, so that the mounting and clampingprecision of all parts of the door body is guaranteed; and the manual operation is not needed, so that the production cost is reduced.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

Shaping mechanism for automobile part processing

PendingCN108714636AGood product consistencyNo manual work requiredMetal-working feeding devicesStripping-off devicesValve seat

The invention provides a shaping mechanism for automobile part processing. The shaping mechanism for automobile part processing is beneficial for consistency of products such as pistons and valve seats, and high efficiency of shaping processing. The shaping mechanism for automobile part processing comprises a feeding device, a shaping mechanism body and a discharging device. The discharging devicecomprises a discharging gripper, a transition rail and a discharging conveyer belt. A discharging baffle is arranged on one side of the discharging conveyer belt. A discharging supporting rack is fixed to the discharging baffle. A sliding block which slides in the horizontal direction is arranged on the discharging supporting rack. The sliding block is provided with a clamping jaw base which slides in the vertical direction along the sliding block. The clamping jaw base is connected with a clamping jaw. The discharging gripper comprises the clamping jaw. The middle of the clamping jaw is hinged to a moving block. The moving block can move in the vertical direction. The tail portion of the clamping jaw is hinged to a connecting rod. The connecting rod is connected with a telescopic mechanism. The moving block is connected with a grabbing support. The shaping mechanism for automobile part processing can achieve automatic operation without workers for manual operation, and is good in product consistency.

Owner:淅川县粉末冶金有限公司

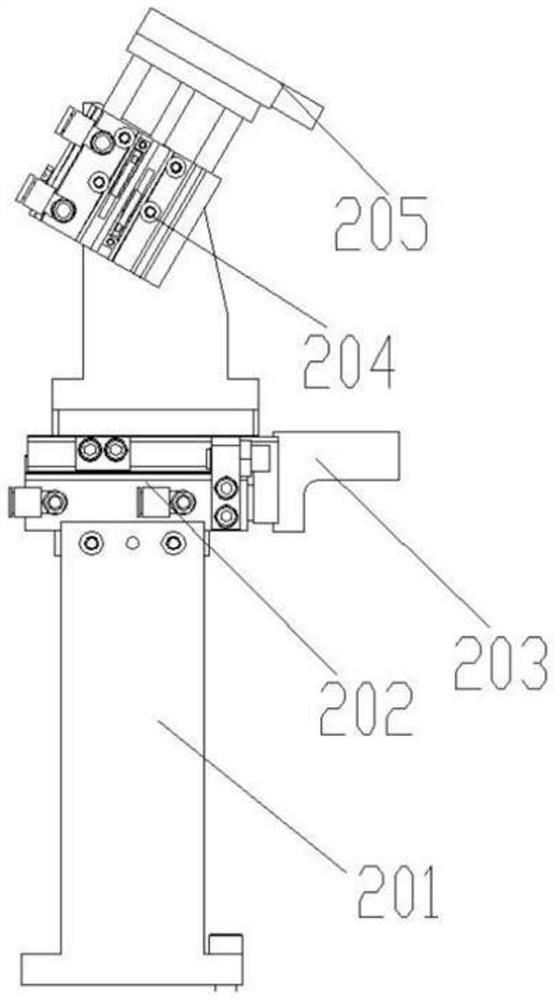

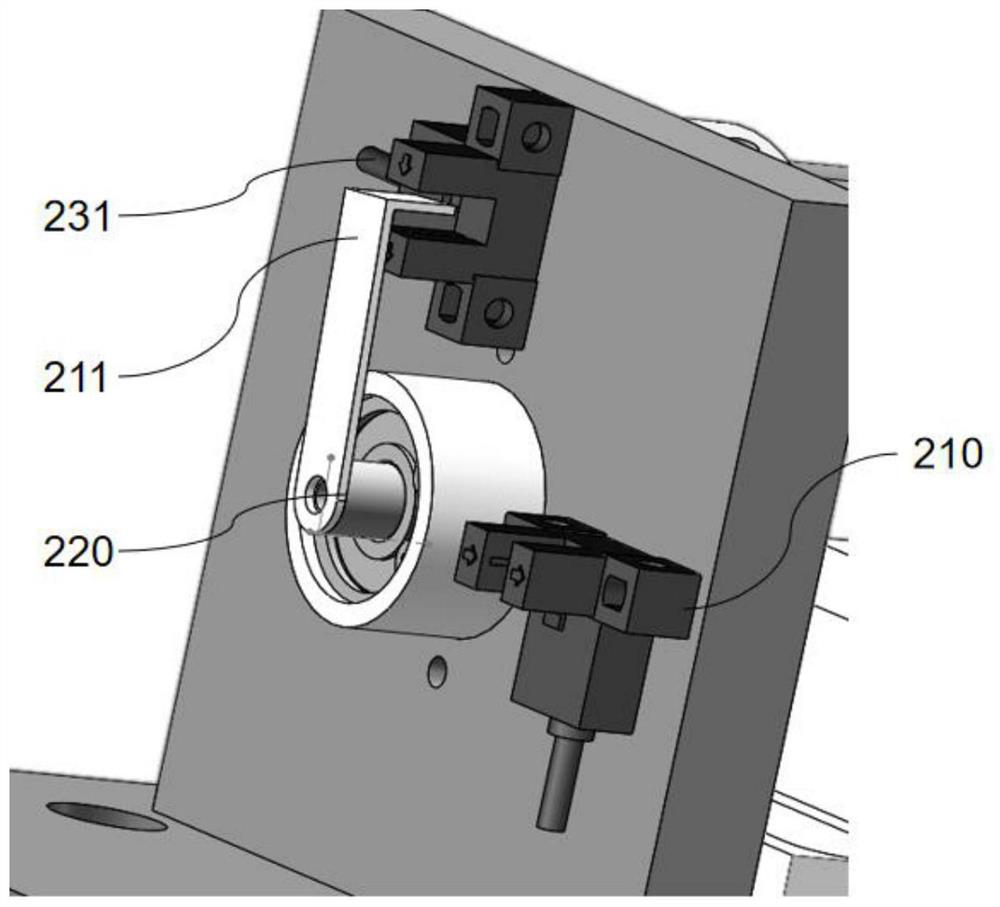

Antenna bending device

PendingCN112453258AAchieve bendingImprove consistencyMetal working apparatusElectric machineControl cell

The invention provides an antenna bending device. The antenna bending device comprises a base, a bending unit, a fixed clamping unit and a control unit, wherein the bending unit and the fixed clampingunit are fixed on the base; the bending unit comprises a rotating motor, a bending shaft and a rotating limiter; the bending shaft is fixed on the rotating motor and is used for bending an antenna ata preset position under the driving of the rotating motor; the rotating limiter is used for limiting the rotating angle of the rotating motor; the fixed clamping unit is used for fixing the bottom ofthe antenna; and the control unit is used for controlling the bending unit and the fixed clamping unit to bend the antenna. When the antenna bending device is used, the antenna is fixed through the fixed clamping unit, the bending unit bends the antenna at a preset angle at a preset position, meanwhile, the control unit controls operation of the device, and due to the fact that the device automatically conducts bending operation, the manual operation is not needed, the manpower is saved, the consistency of antenna bending is good, and the problem of how to improve the consistency of antenna bending is solved.

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO

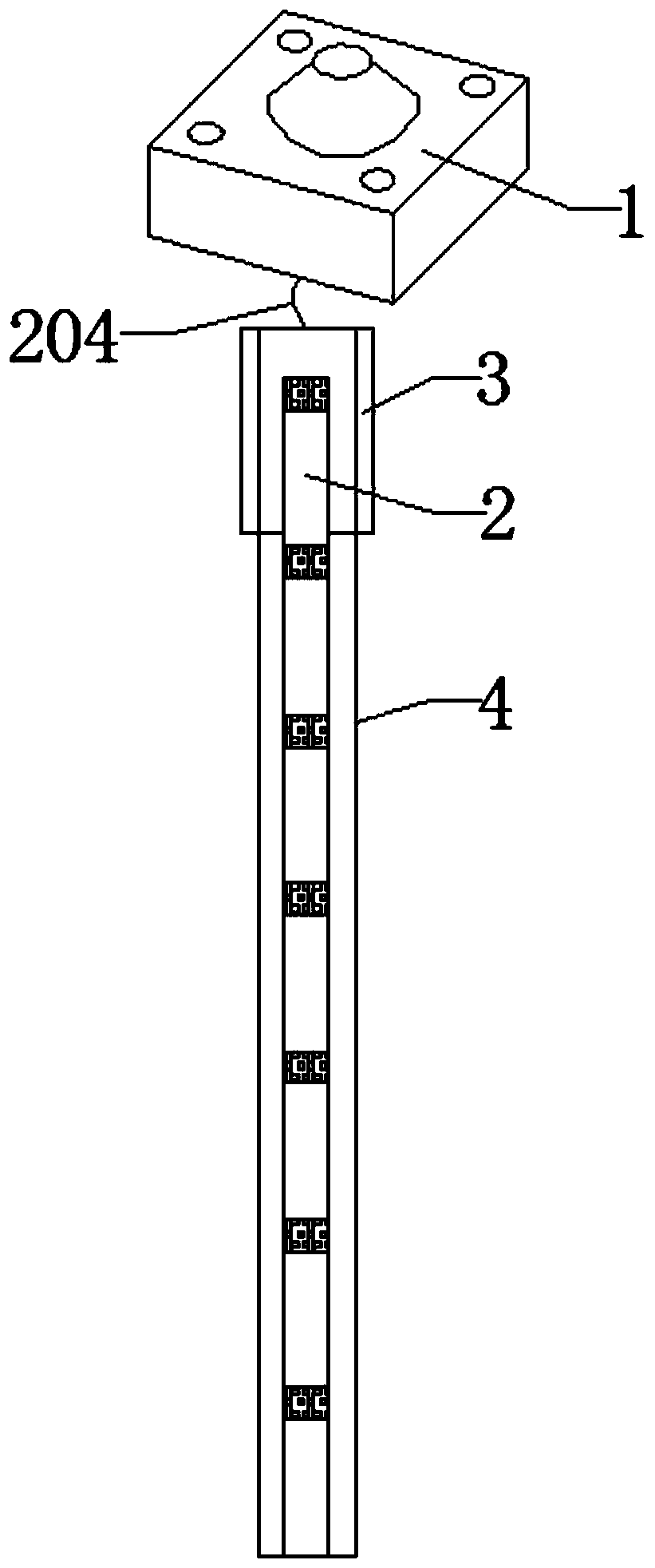

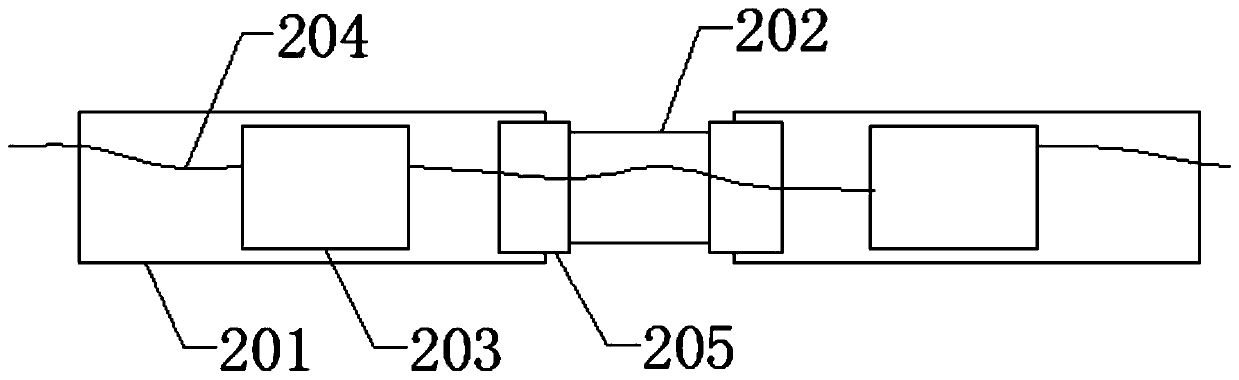

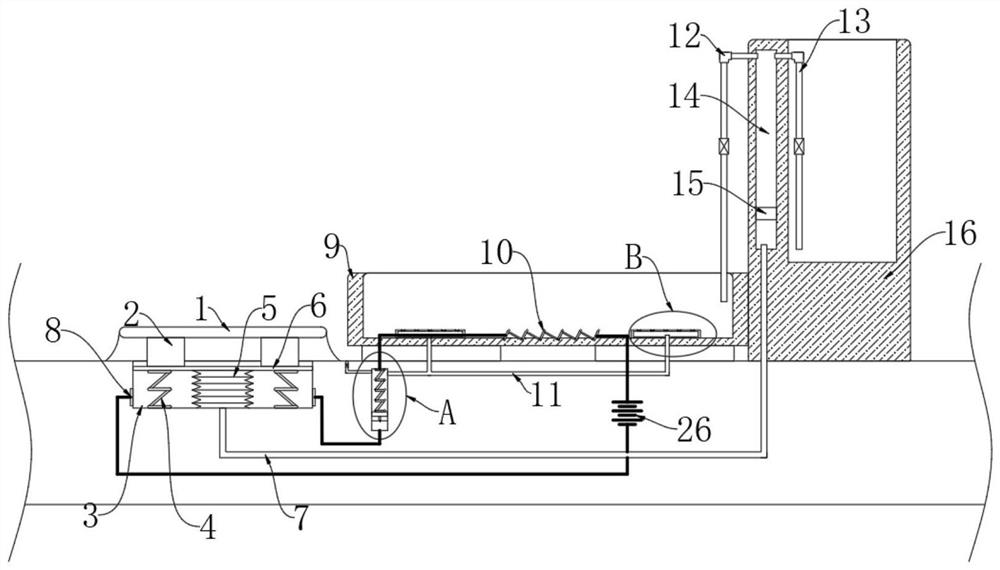

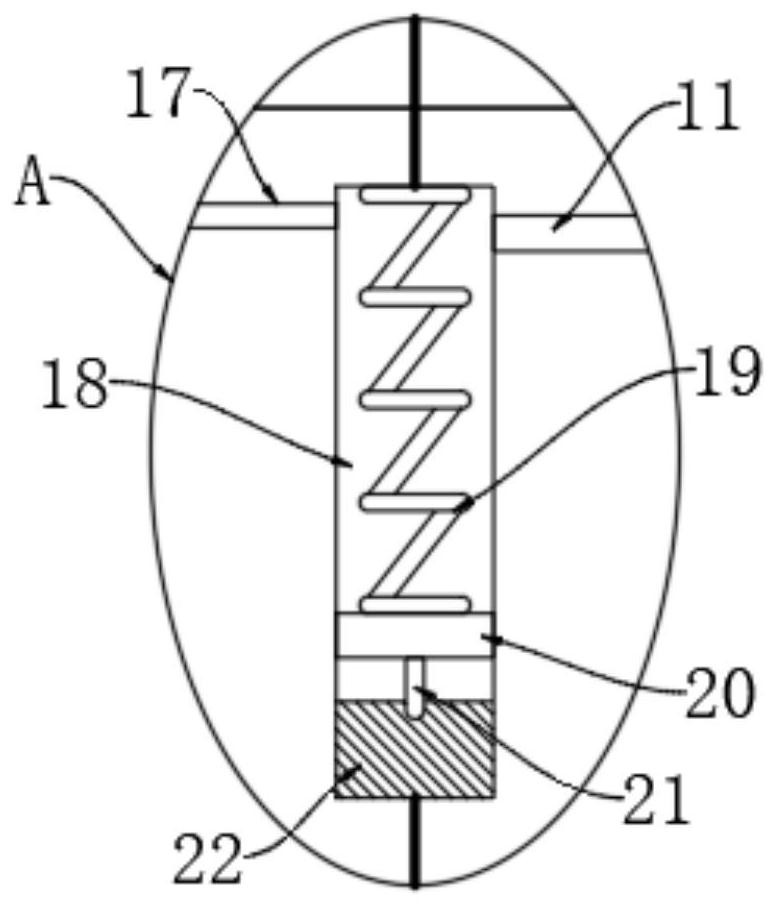

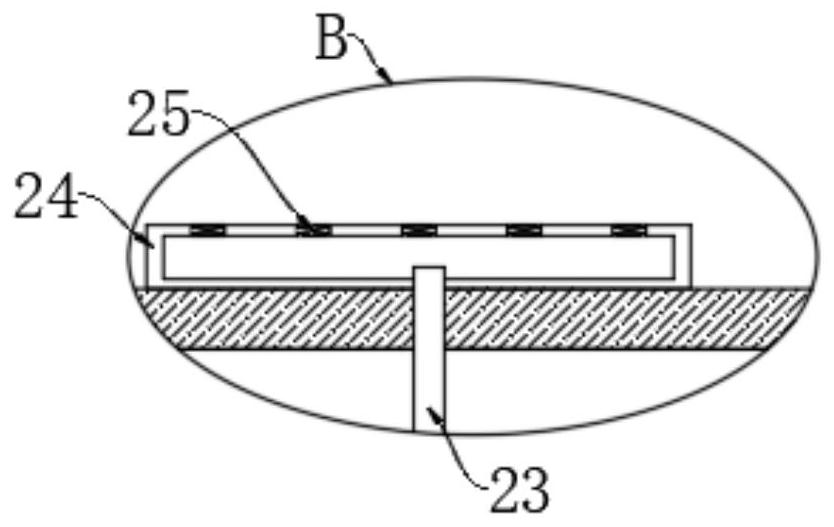

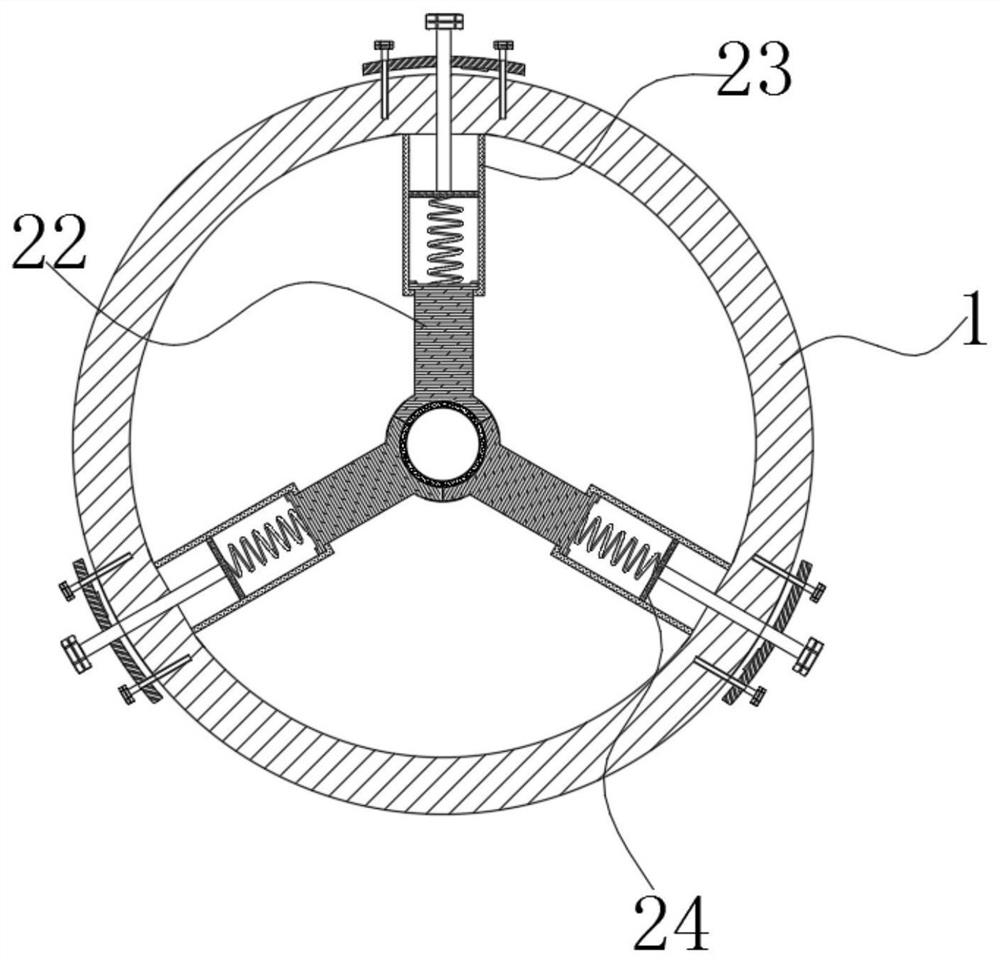

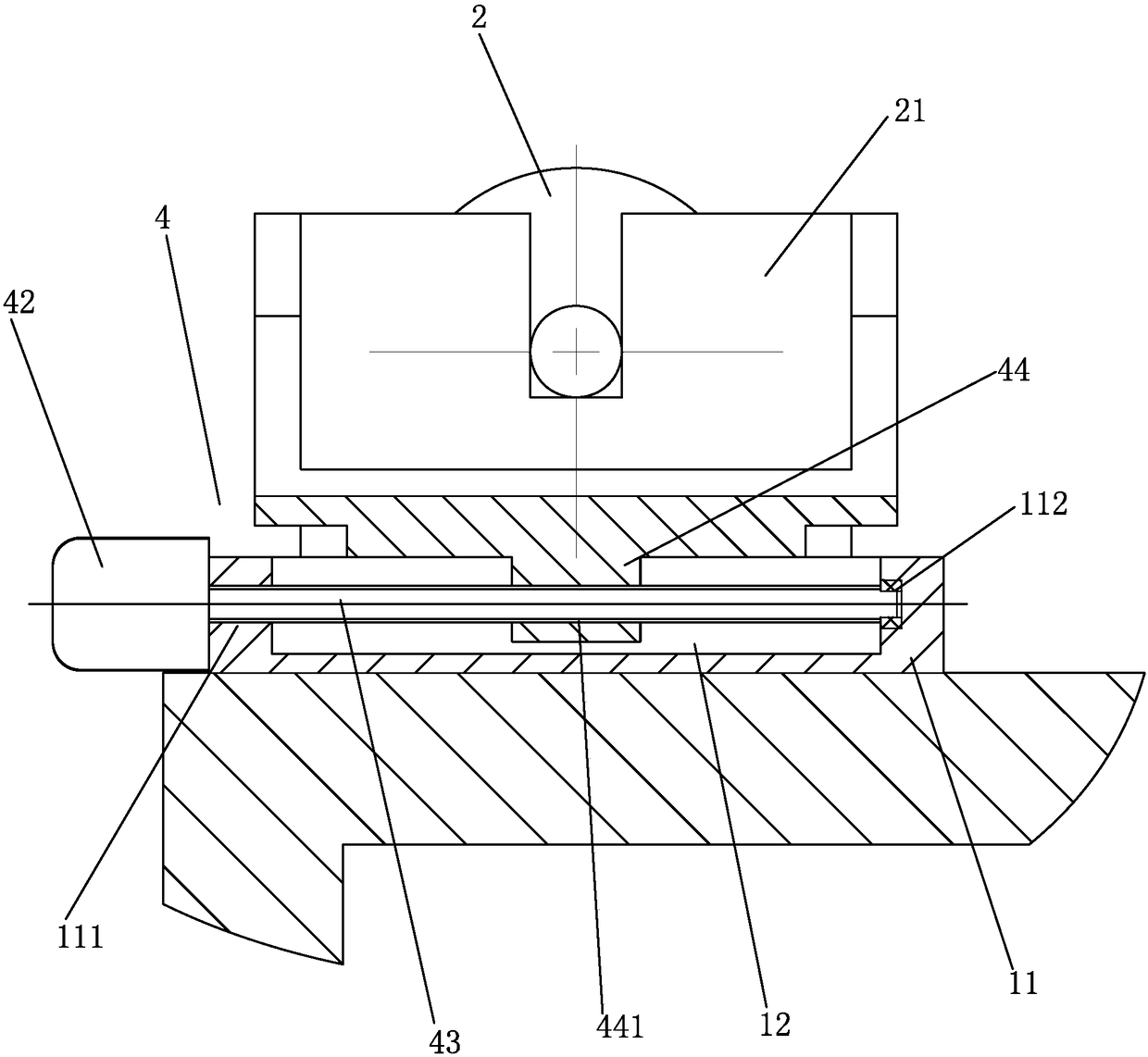

Electromagnet lifting sling of paint spraying device of railway train coupler part

InactiveCN104512797AAutomate operationsNo manual work requiredLoad-engaging elementsMechanical engineeringElectromagnet

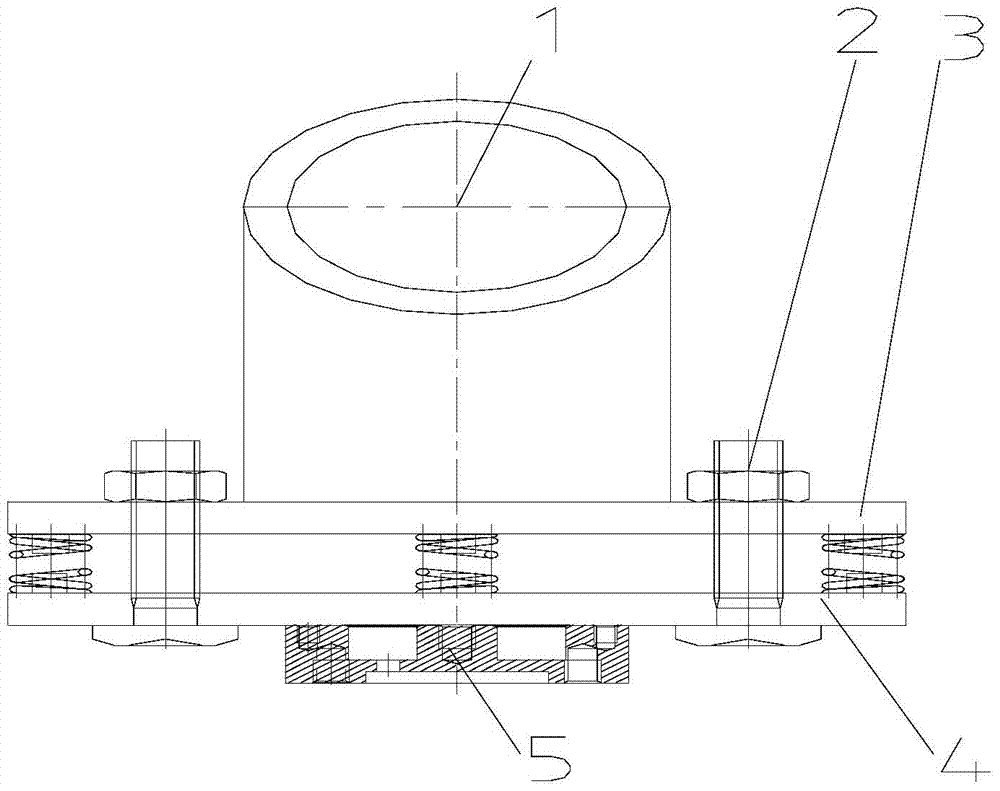

The invention relates to an electromagnet lifting sling of a paint spraying device of railway train coupler parts. The electromagnet lifting sling comprises: a hook body (1), a sliding groove connecting bolt (2), an adjustment spring (3), an electromagnet connecting plate (4), and an annular electromagnet (5). The electromagnet lifting sling of the paint spraying device of the railway train coupler parts is characterized in that the electromagnet lifting sling adsorbs and hangs the railway train coupler parts through the annular electromagnet (5) and unloads the railway train coupler parts by powering-off the annular electromagnet (5). The electromagnet lifting sling is mainly advantaged in that by means of the electromagnet as the lifting sling, automated operation of on-line and off-line of the railway train coupler parts is achieved and no manual operation is required when the train coupler parts is hooked or picked off, thereby greatly reducing labor cost.

Owner:NINGXIA ZHONGYUAN TIANSHENG TECH

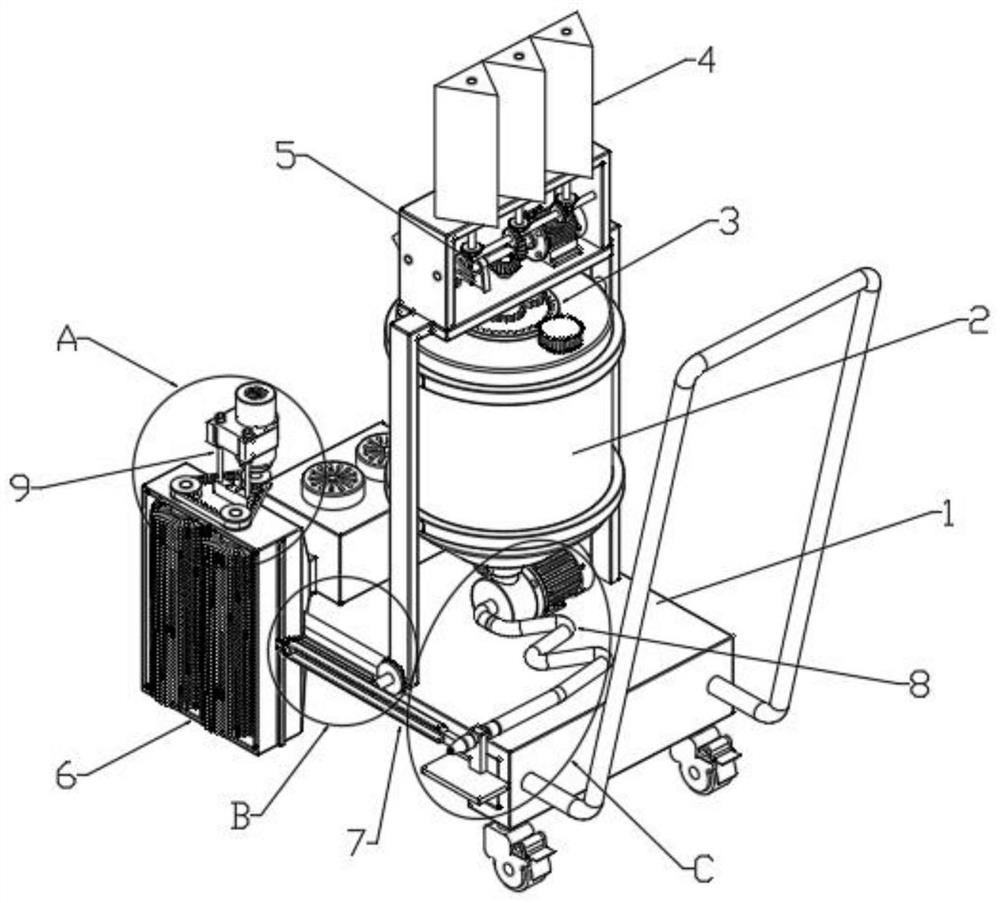

Pasture grass silage fermentation device

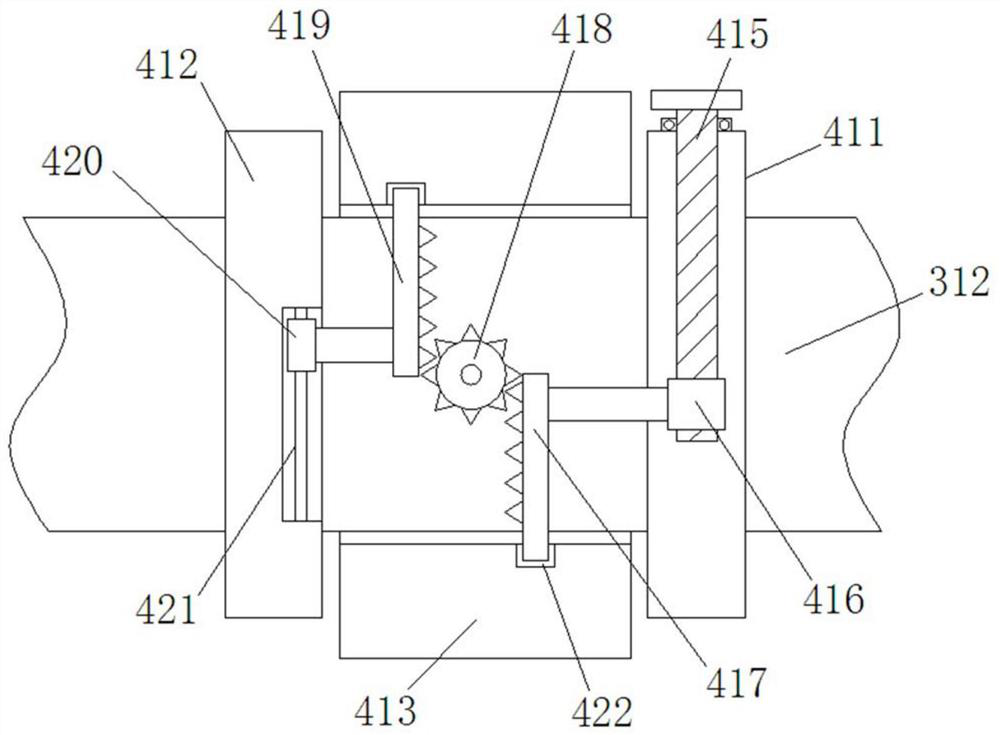

PendingCN112300894APrevent rotEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural scienceGear wheel

The invention relates to a pasture grass silage fermentation device, which comprises a box and a cover mounted on the top of the box, and further comprises a driving rack and a pressing plate, and thedriving rack penetrates through the cover and extends to one end in the box, which is fixedly connected to the pressing plate; and further comprises a driving device drives the driving rack and the pressing plate to do vertical reciprocating motion, which is used for pressing pasture grass, the driving device comprises a driving motor, a first rotating rod and a driving gear, and the driving motor is installed on the top of the cover. The first rotating rod and the driving gear are driven to rotate under the work of the driving motor, at the moment, the pressing plate can press pasture grass,and meanwhile, a second rotating rod is driven to rotate under the action of a transmission device, so that two sets of screw rods rotate, and two sets of movable blocks and two sets of clamping blocks are driven to do separation movement under the action of threads, so that the two sets of clamping blocks are embedded into two sets of clamping grooves respectively, the box and the cover can be fixed in this way, the operation is convenient, no manual operation is needed, and rotting of forage grass is avoided.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Work fixture for grabbing injection parts of doll toy

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

A water feeding system for animal husbandry with mixed functions

The invention discloses a water feeding system for animal husbandry with a mixing function, which comprises a box body, the box body is arranged on the ground, a water storage chamber is arranged at the upper end of the box body, and a A bar-shaped cavity, the ground is provided with a water tank, the water tank is located on the left side of the box, and a chute is opened on the ground; a stepping trigger mechanism, the stepping trigger mechanism includes a conductive plate sliding up and down connected in the chute, the conductive plate Two connection blocks are symmetrically and fixedly connected above the plate, and the upper ends of the two connection blocks are fixedly connected with a load-bearing plate, and the lower end of the conductive plate is elastically connected to the inner bottom of the chute through two connection springs. The water feeding system is triggered by the animal stepping on the load-bearing plate, so that the water is injected into the tank without manual water injection, which reduces the use of labor. At the same time, the temperature of the water can be controlled, and a mixing mechanism is provided, which greatly improves the system. Adaptability to use.

Owner:LUAN LONGXIANG MEISHIWANG POULTRY IND CO LTD

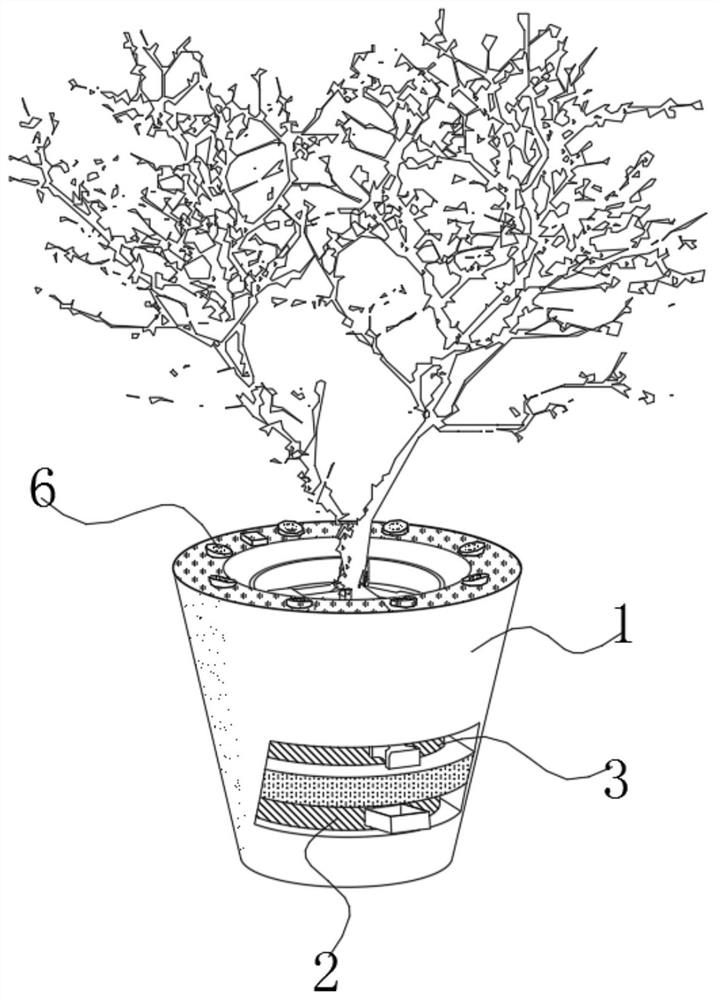

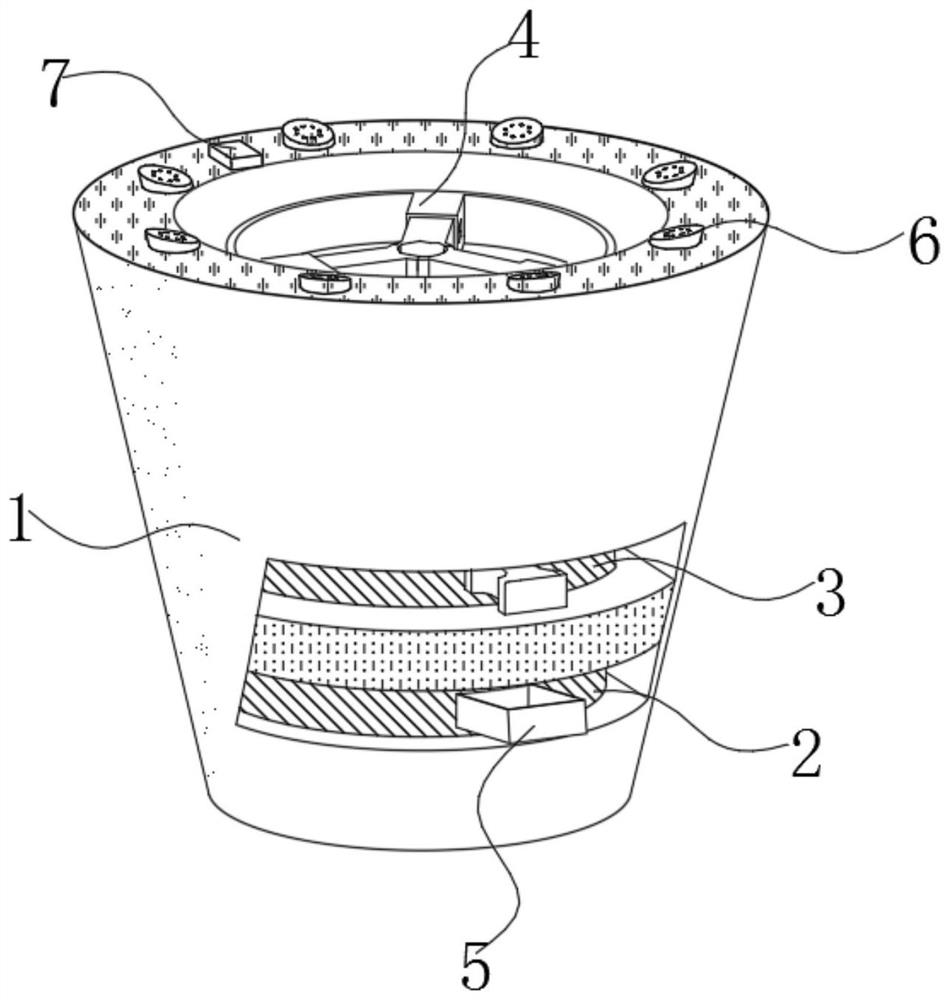

Potted chimonanthus praecox soilless culture device

ActiveCN111616041AGuaranteed vertical growthImprove fitAgriculture gas emission reductionCultivating equipmentsCulture fluidPeat

The invention discloses a potted chimonanthus praecox soilless culture device. The potted chimonanthus praecox soilless culture device comprises a pot body, a supporting base, a guide cylinder and a righting early warning assembly, wherein the supporting base which is provided with a through hole and is a rotary body is fixedly attached to the inner wall of the middle of the pot body; an elastic dense net is fixed in the supporting base, and a loading space is formed between the elastic dense net and the supporting base, wherein the loading space is used for loading one or more of quartz sand,vermiculite, peat and plastic; a clamping limiting channel is formed between the elastic dense net and the through hole of the supporting base; the guide cylinder is coaxially fixed to the upper portion of the supporting base; and the righting early warning assembly is arranged above the guide cylinder. During installation, a main rod of the chimonanthus praecox sequentially penetrates through the righting early warning assembly, the guide cylinder and the clamping limiting channel, so that the root of the chimonanthus praecox enters a culture solution box in the pot body.

Owner:SICHUAN AAS HORTICULTURE RES INST

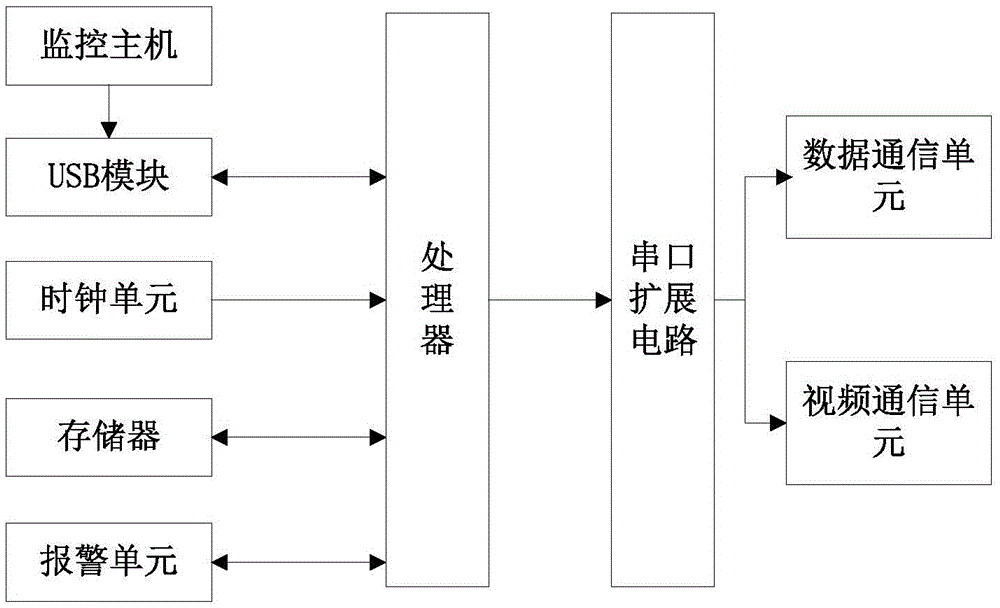

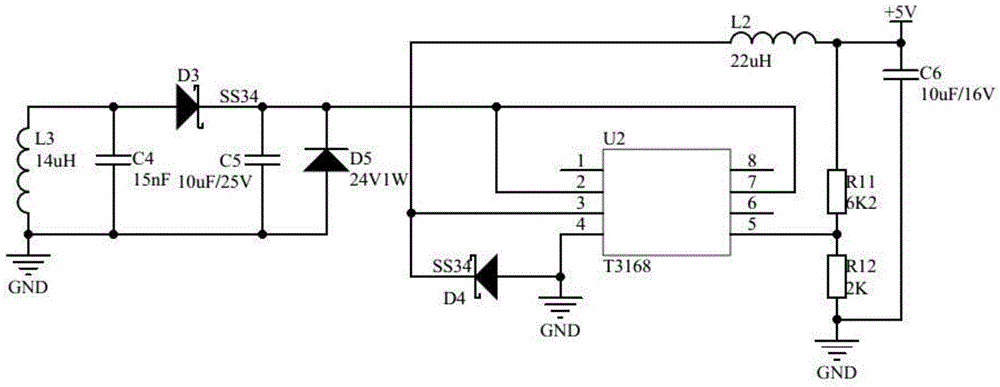

Electronic shoe for railway

ActiveCN105584503ARealize monitoringNo manual work requiredRailway signalling and safetyCommunication unitRemote control

The invention provides an electronic shoe for a railway. The electronic shoe comprises a shoe body. A processor is arranged in the shoe body and connected with a cache memorizer, an alarming unit, a charging module and a clock unit. The processor is connected with a data communication unit and a video communication unit through a serial port expander circuit. The shoe body is connected with a monitoring host and a handheld remote control end through the data communication unit. The processor determines rail position information of the shoe body through the video communication unit and controls the alarming unit to give out corresponding prompts according to a rail position. The monitoring host is used for receiving the rail position information of the processor and monitoring the rail position of the shoe body in real time. The condition of the rail position of the electronic shoe can be monitored in real time, alarms are automatically given out during illegal motion, and the safety of the railway is guaranteed.

Owner:TIANJIN MINTONG YOUWEI TECH DEV

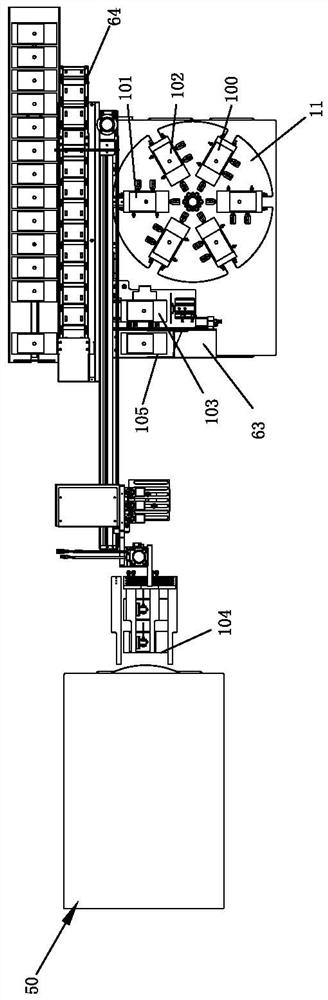

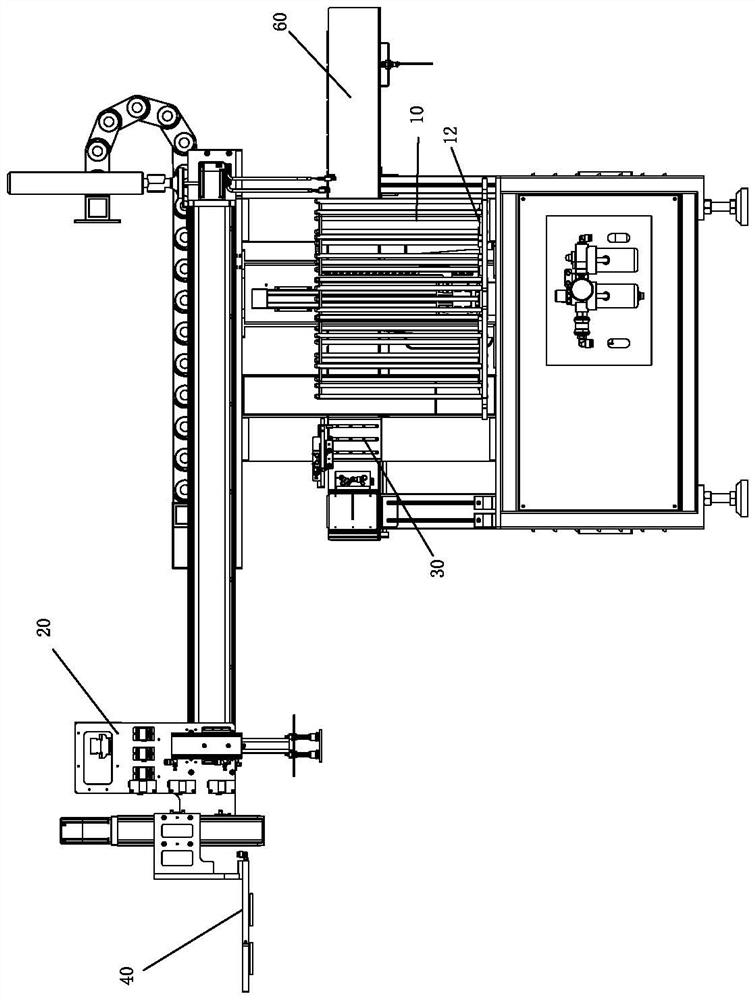

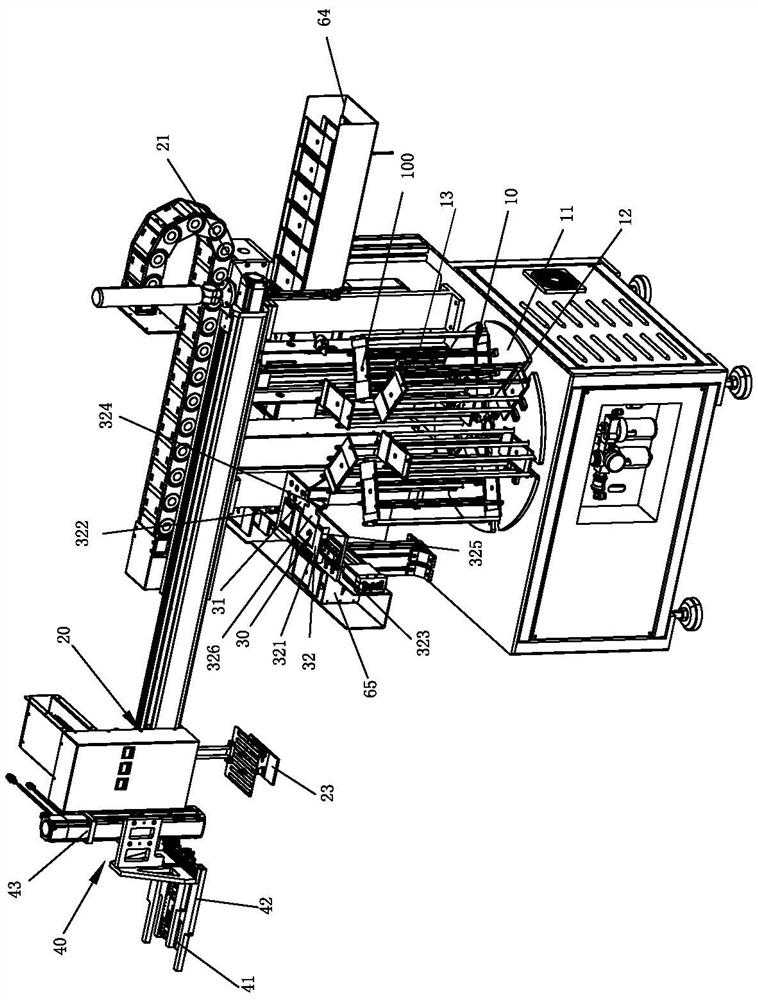

Automatic feeding and discharging machining method for mobile phone middle frame with Z axis

ActiveCN113942809AReduce labor costsLabor savingStacking articlesDe-stacking articlesRobot handControl engineering

The invention discloses an automatic feeding and discharging machining method for a mobile phone middle frame with a Z axis. The method comprises five steps of plate placing, plate taking, positioning, machining and discharging, all the steps are fully automatic, manual participation is not needed, and the labor cost is effectively reduced. The plate placing mechanism can supply a large amount of materials, a feeding mechanical arm moves the mobile phone middle frame from a feeding station to a positioning station, the positioning mechanism positions the mobile phone middle frame, a discharging mechanical arm loads the positioned mobile phone middle frame to a machining station and puts the machined mobile phone middle frame into a recycling mechanism, and an automatic machine is used for machining the mobile phone middle plate at the machining station. Due to the fact that automatic feeding is achieved, and feeding is positioned, the working efficiency and accuracy of a feeding and discharging machine are very high; and in addition, the discharging mechanical arm is of a Z-axis structure, the unmachined mobile phone middle frame can be moved to the machining station, the machined mobile phone middle plate can be moved to a discharging station, the two actions are carried out synchronously, and the working efficiency is improved advantageously.

Owner:深圳市乐桥科技有限公司

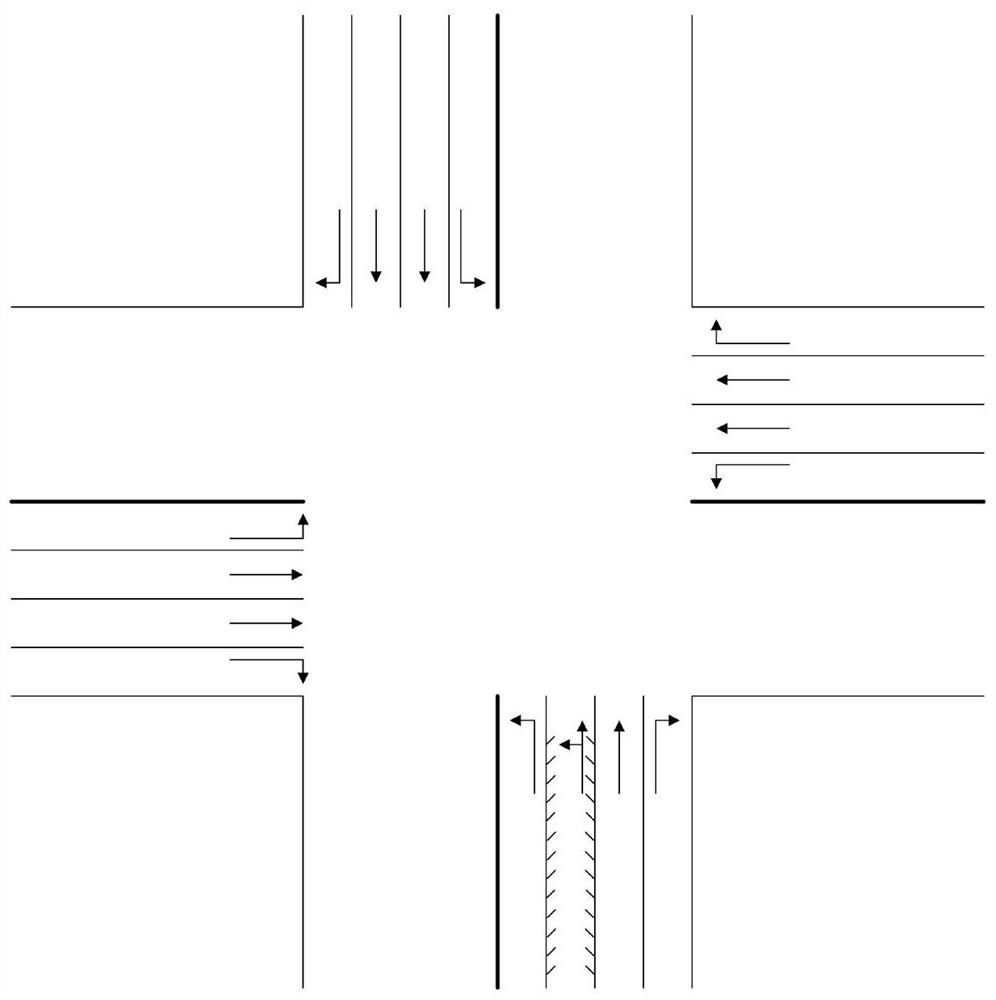

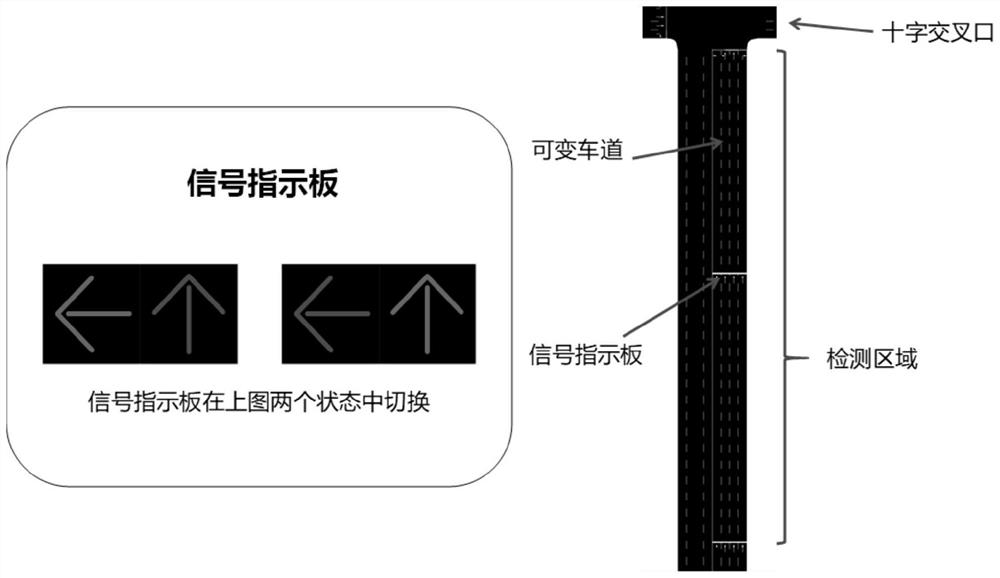

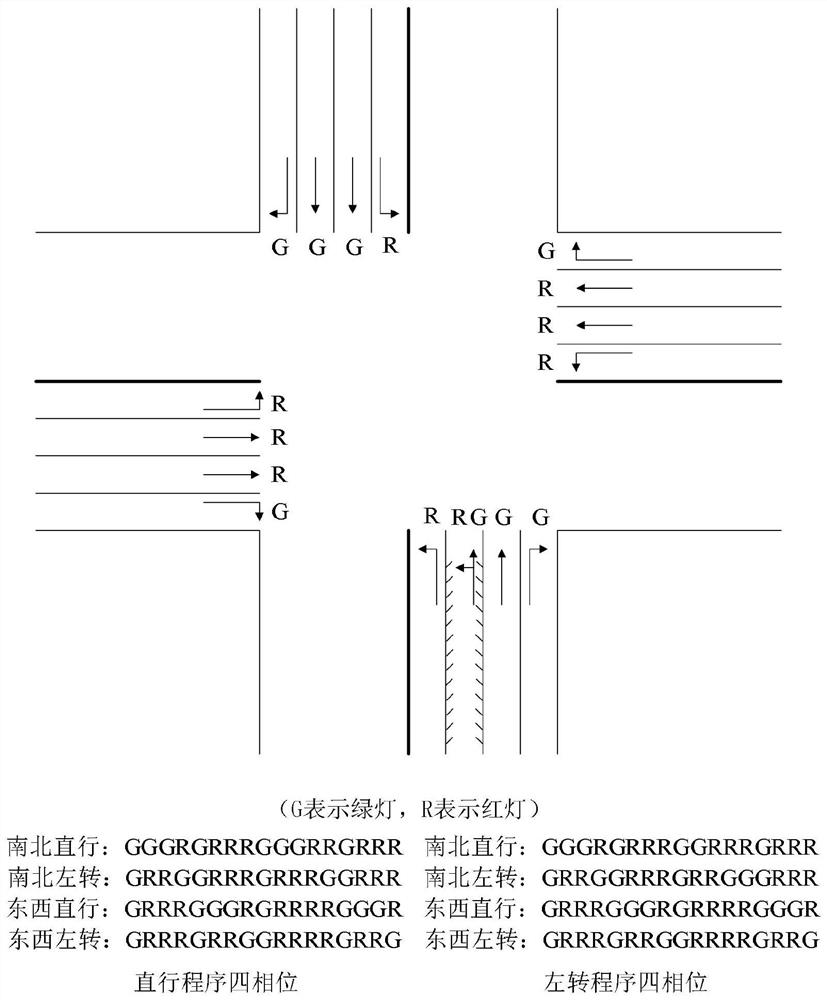

Collaborative control method for variable lanes and traffic signals based on deep reinforcement learning

ActiveCN111915894BRealize coupling controlNo secondary parkingControlling traffic signalsDetection of traffic movementTraffic signalSimulation

The invention discloses a method for collaborative control of variable lanes and traffic signals based on deep reinforcement learning, which includes collecting state observations at intersections, including vehicle data, signal light data, and variable lane data, and inputting them to the neural network after preprocessing ; The neural network is continuously trained and updated based on reinforcement learning until the model converges; optimal control is performed based on the trained neural network, and an optimal control strategy is output. The present invention realizes the coupling control of the variable lane and the traffic signal, and can perform real-time optimal control according to the real-time state of the intersection area, without manual work, and the switching of the variable lane and the control of the traffic signal are completely based on the traffic flow The data is adaptively adjusted, and there is no secondary parking of vehicles, which optimizes the utilization efficiency of time and space resources at signal-controlled intersections.

Owner:BEIHANG UNIV

Asphalt filling device for highway bridge maintenance

InactiveCN114808768AStir wellImprove melting efficiencyTraffic signalsBridge erection/assemblyVehicle frameArchitectural engineering

The invention discloses an asphalt filling device for highway bridge maintenance, particularly relates to the technical field of highway bridge maintenance, and aims to solve the problems that when a gap appears on the side wall of a current highway bridge, asphalt is mostly manually filled in the gap, so that manpower is wasted, a corresponding warning mechanism is not arranged during manual operation, and the working efficiency is high. The asphalt melting device comprises a movable frame, a U-shaped frame is fixedly installed on the movable frame and can drive stirring blades and a stirring barrel to rotate synchronously, and the rotating directions of the stirring blades and the stirring barrel are opposite, so that asphalt can be quickly and uniformly stirred, and the melting efficiency of the asphalt can be effectively improved; the triangular warning plates can be driven by the fifth rotating rods to intermittently rotate by 60 degrees, so that three side surfaces of the three groups of triangular warning plates can be sequentially spliced, three danger warning words can be sequentially and circularly displayed at equal intervals, and a good warning and reminding effect can be further achieved.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

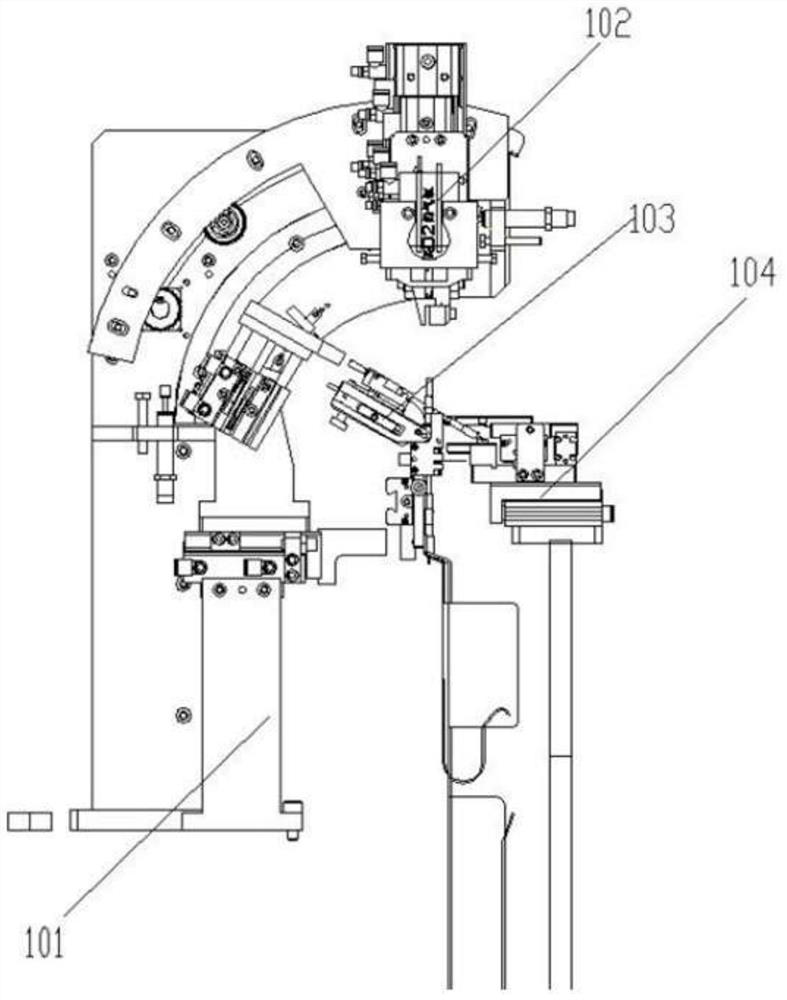

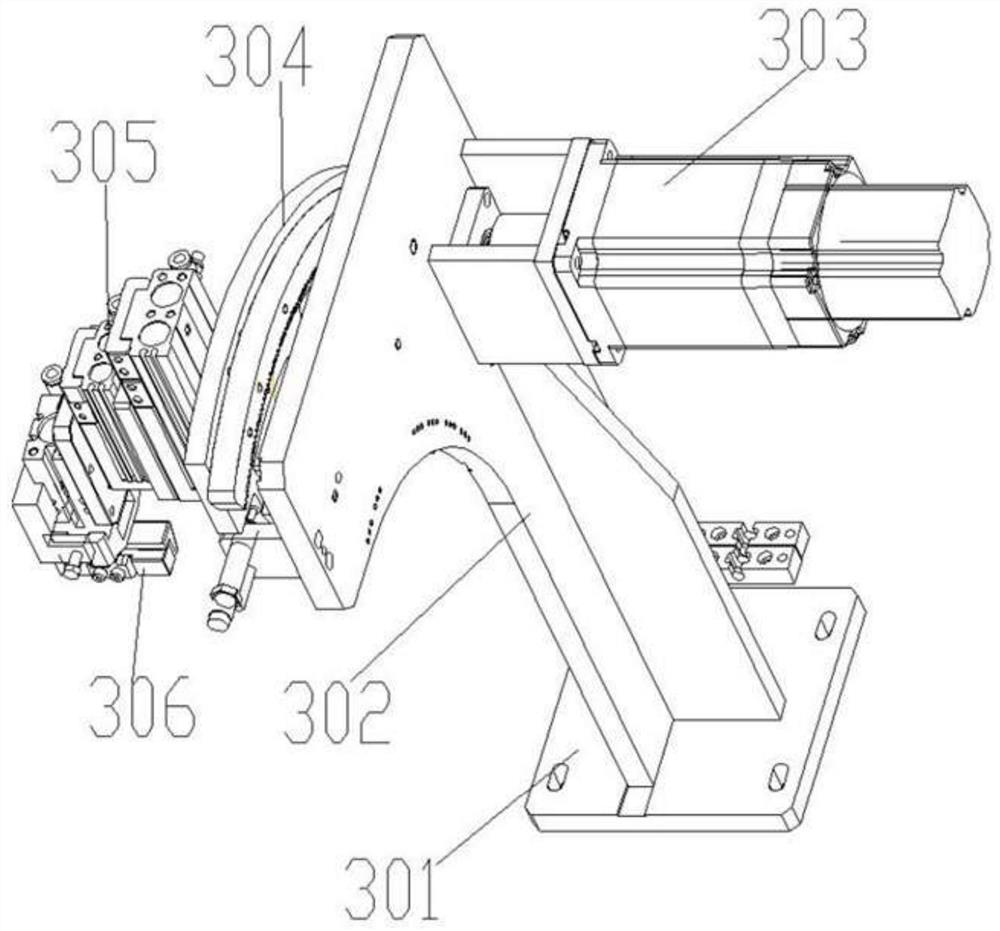

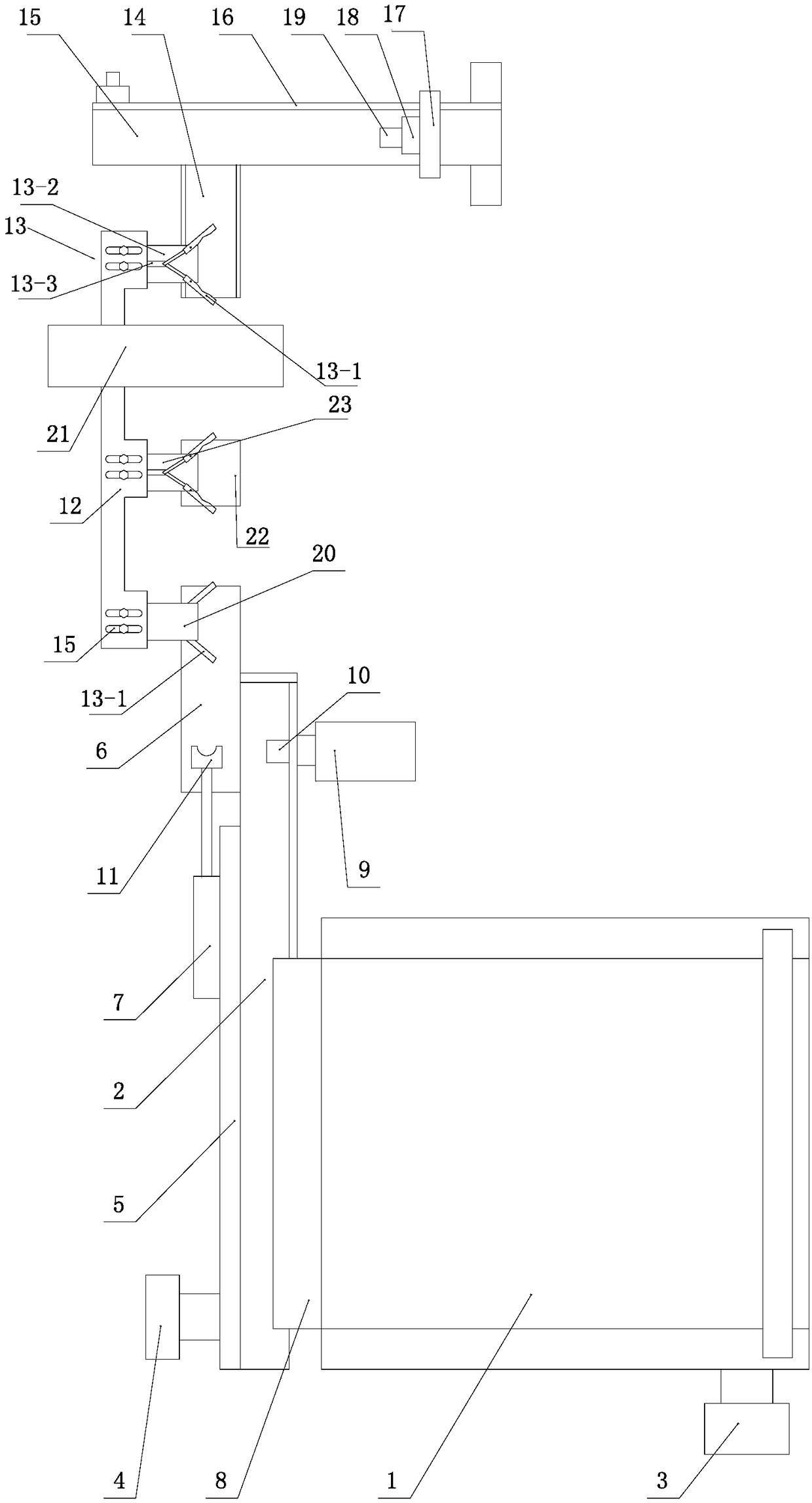

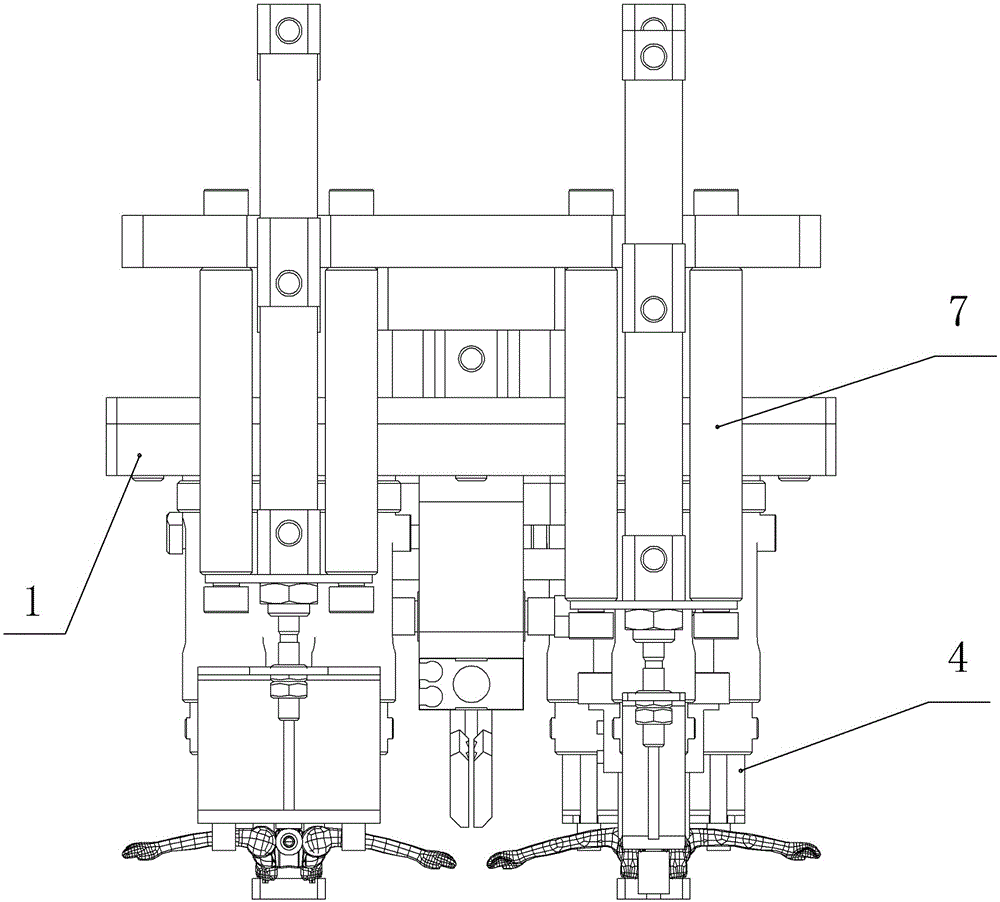

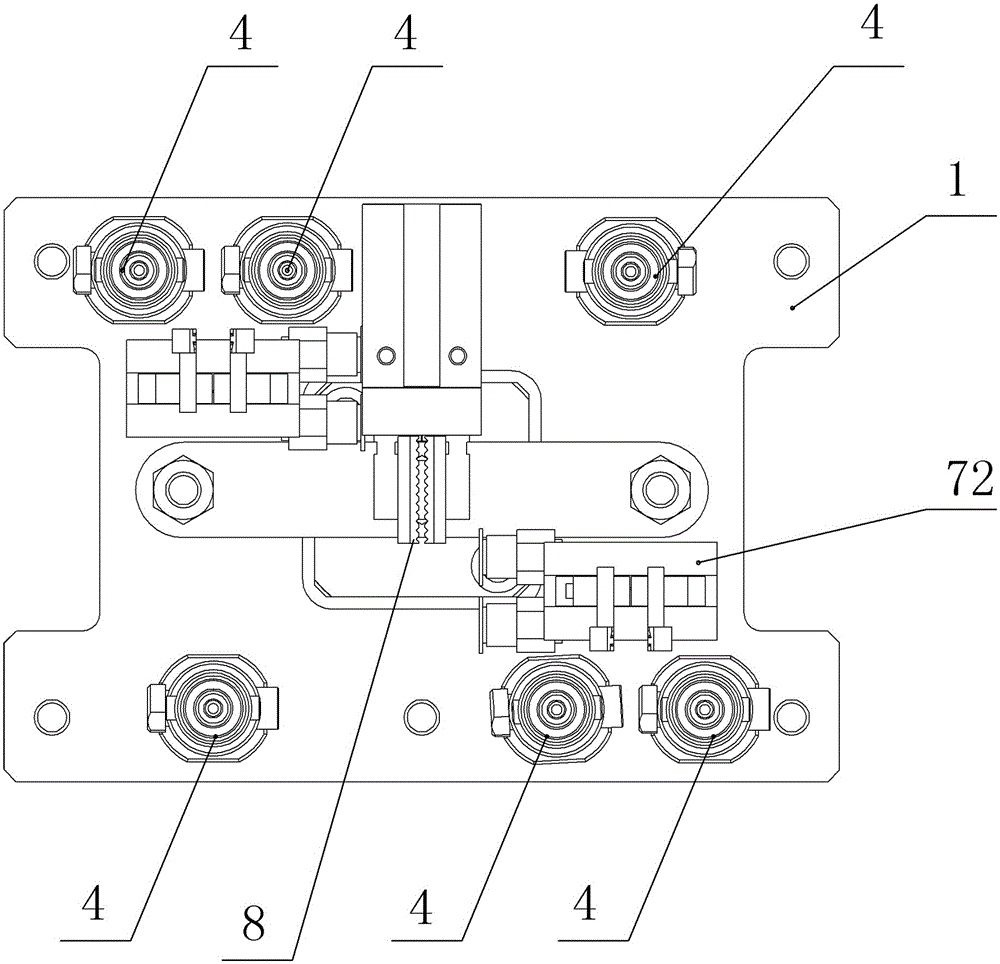

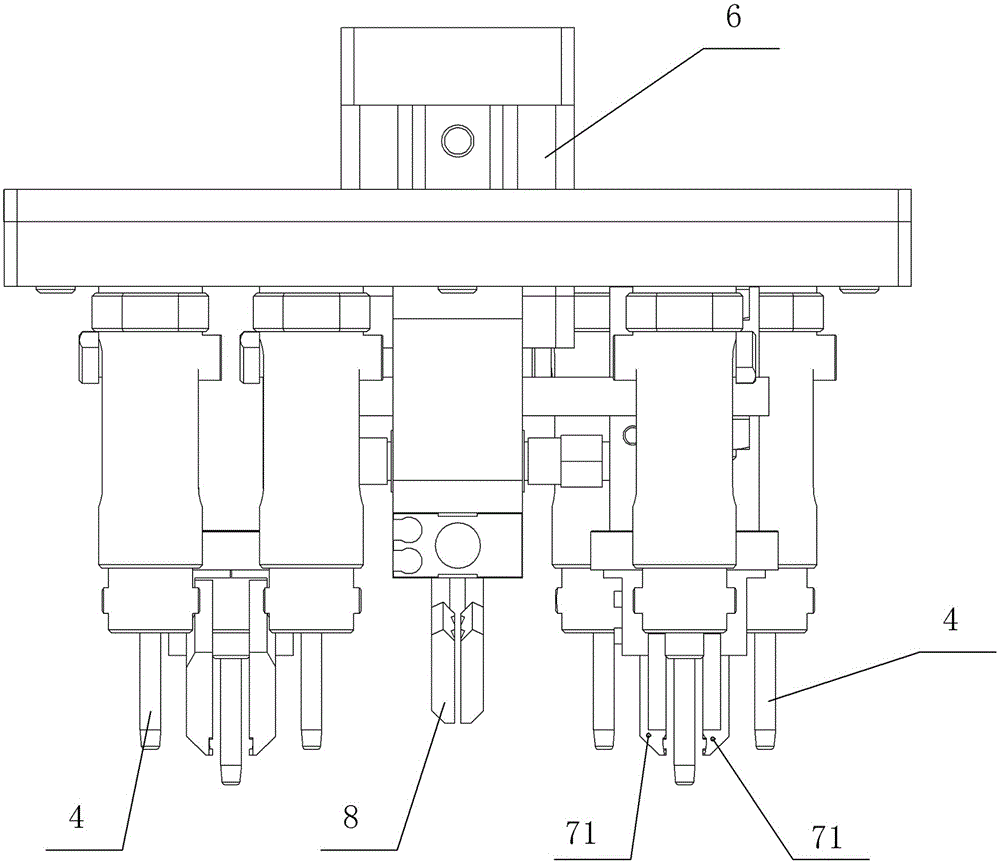

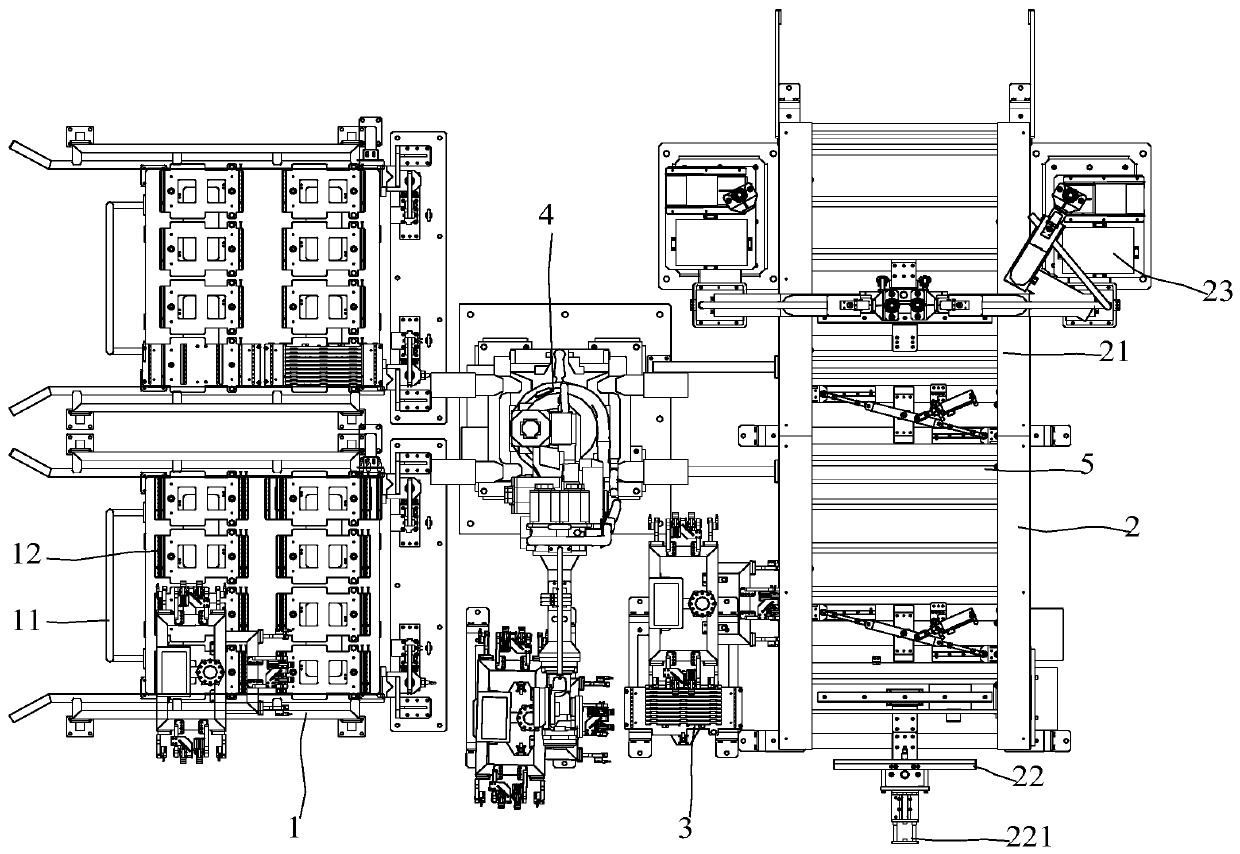

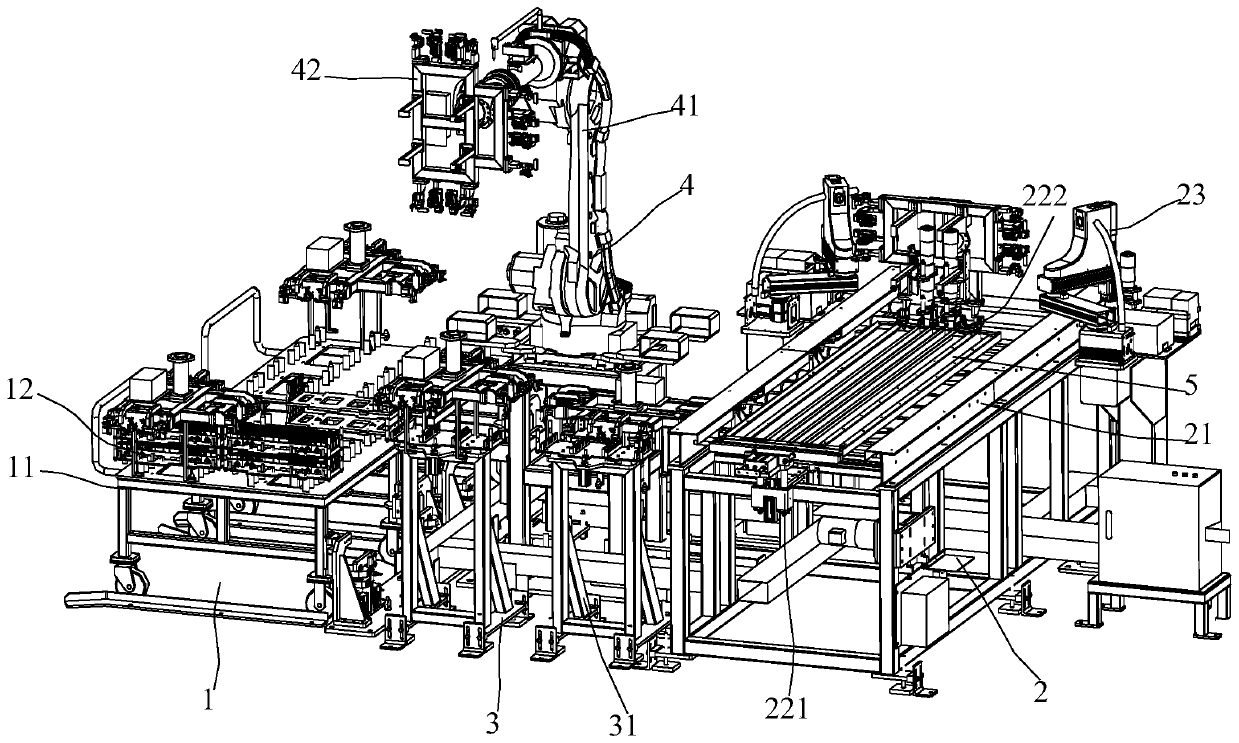

An assembly system and assembly method of elevator floor door panel guide shoes

ActiveCN107309385BImprove assembly efficiencyNo manual work requiredStructural engineeringMechanical engineering

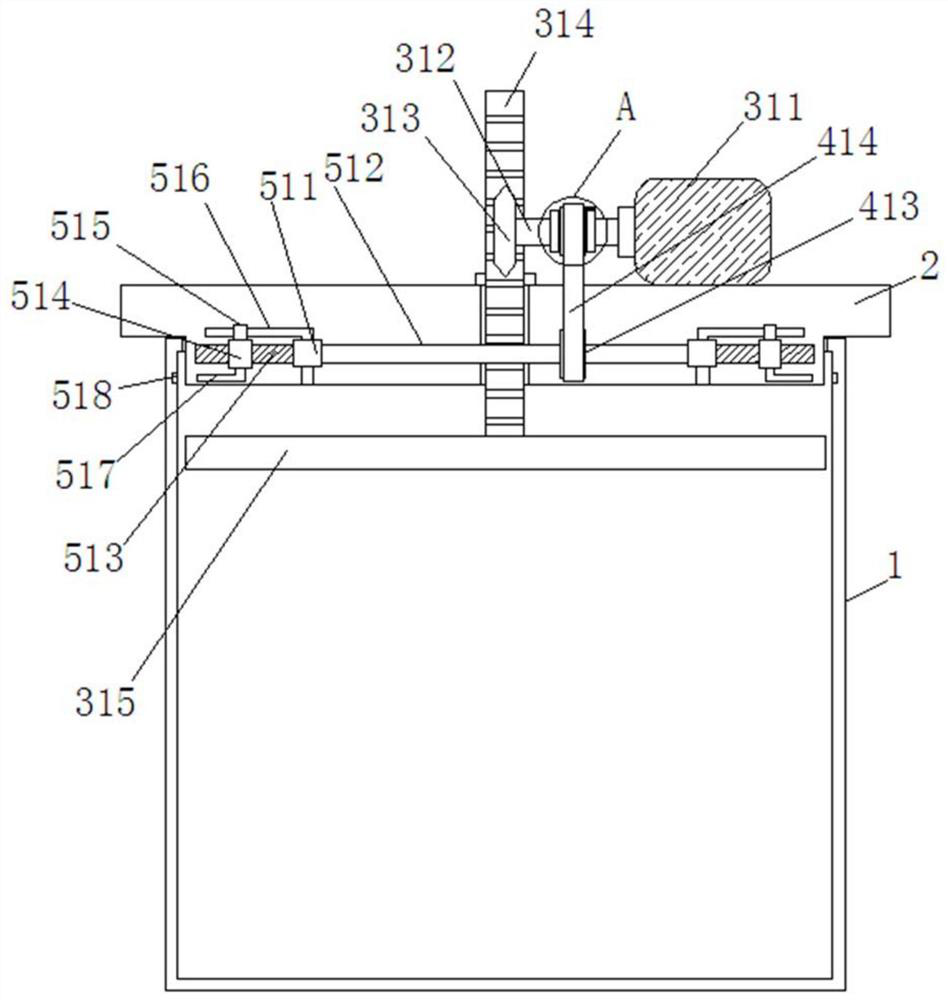

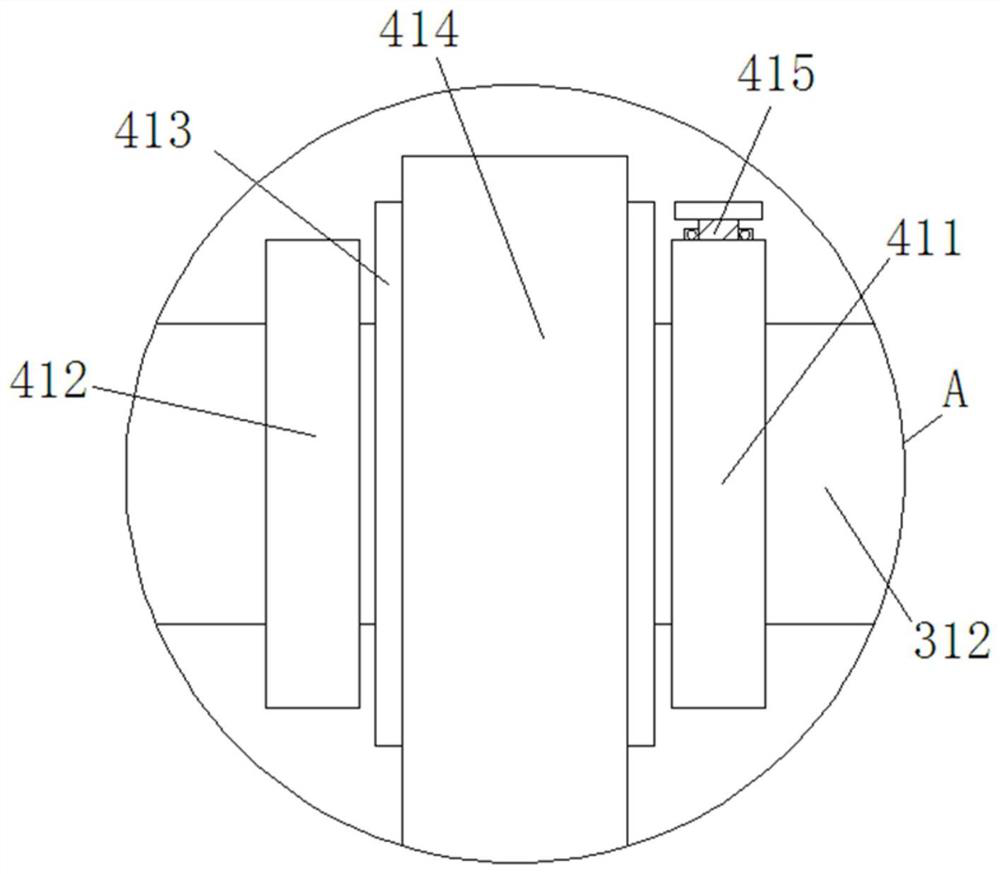

The invention discloses an assembling system and assembling method for guide shoes of an elevator layer door sheet. The assembling system comprises a guide shoe storing area, a guide shoe installing area, an intermediate transiting platform and a guide shoe grabbing mechanism. The intermediate transiting platform is located between the guide shoe storing area and the guide shoe installing area, a plurality of trolleys are arranged at the guide shoe storing area, and a plurality of containing frames used for storing the guide shoes are arranged on the trolleys; the guide shoe installing area is provided with a installing platform, a limiting mechanism and a plurality of automatic riveting machine, the installing platform is used for storing the elevator layer door sheet, and the limiting mechanism is arranged on the installing platform; and the guide shoe grabbing mechanism is used for grabbing the containing frames fully filled with the guide shoes to the intermediate transiting platform, and a single piece of the guide shoe is grabbed to the elevator layer door sheet of the installing platform. During the guide shoe assembling process, the elevator layer door sheet is stored on the installing platform; the single piece of the guide shoes is grabbed onto the elevator layer door sheet by the guide shoe grabbing mechanism; and by installing rivets between the guide shoes and the elevator layer door sheet through the automatic riveting machine, the guide shoes are assembled on the elevator layer door sheet accordingly, and assembling efficiency of the guide shoes is improved.

Owner:GUANGZHOU RUISONG INTELLIGENT TECH CO LTD

Device for production of power box

InactiveCN107322302ANo manual work requiredPressing and fixing with high precisionWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringSteel plates

The invention discloses a device for production of a power box. The device is used for welding a steel plate and at least comprises a supporting table, a supporting plate, a power mechanism, a pressing part and a welding part, wherein the supporting plate is slidably connected with the supporting table; the power mechanism is used for driving the supporting plate to move in the length direction of the supporting table; the pressing part is used for pressing the steel plate; the welding part is used for welding the steel plate and comprises a sliding rod, a first driving unit, a second driving unit, a welding gun assembly and a branch pipe, and the sliding rod is arranged above the supporting plate horizontally; the first driving unit is slidably connected with the sliding rod and used for driving the welding gun assembly to move in the vertical direction; the second driving unit is used for driving the first driving unit to move in the length direction of the sliding rod; and the branch pipe is connected with the first driving unit and arranged outside the welding gun assembly.

Owner:芜湖锐华暖通科技股份有限公司

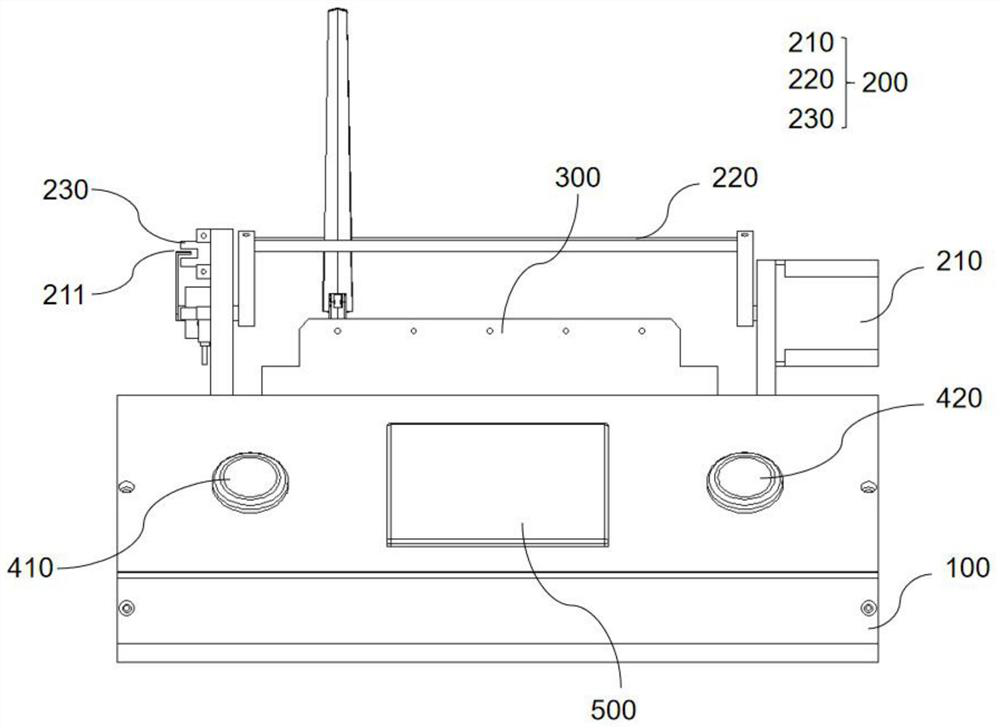

Automatic deviation adjusting device for waterproof coiled material production line

InactiveCN109132652ARealize the effect of offset adjustmentEasy to adjustWebs handlingProduction lineEngineering

The invention relates to waterproof coiled material production equipment, in particular to an automatic deviation adjusting device for a waterproof coiled material production line. The device comprises a support, wherein an unwinding roller is arranged at one end of the support, a winding roller is arranged at the other end of the support, the unwinding roller and the winding roller are arranged in parallel, an unwinding roller support is arranged at the axial two ends of one end, provided with the unreeling roller, of the support, the unwinding roller is erected on the unwinding roller support, a deviation adjusting device capable of adjusting the position of the unreeling roller support is arranged between the unreeling roller support and the support, a winding roller support is arrangedat the axial two ends of one end, provided with the winding roller, of the support, the winding roller is erected on the winding roller support, and a second deviation adjusting device capable of adjusting the position of the winding roller support is arranged between the winding roller support and the support. The invention provides the automatic deviation adjusting device, capable of automatically adjusting the positions of the rollers, for the waterproof coiled material production line.

Owner:湖北蓝盾之星科技有限公司

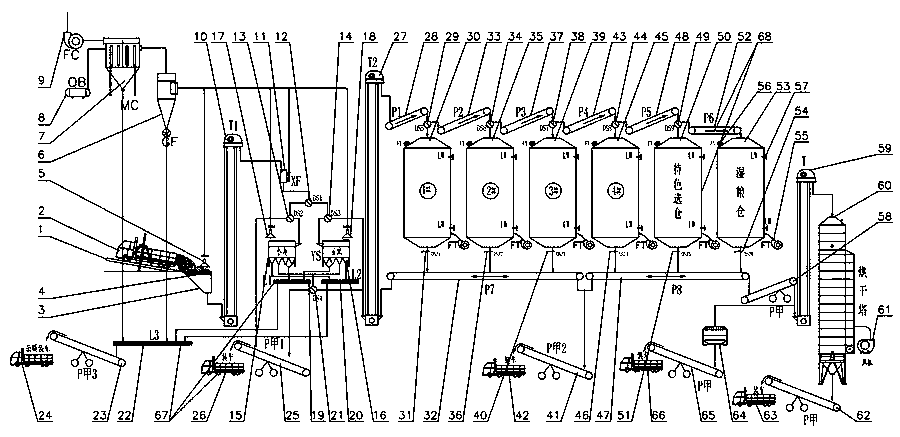

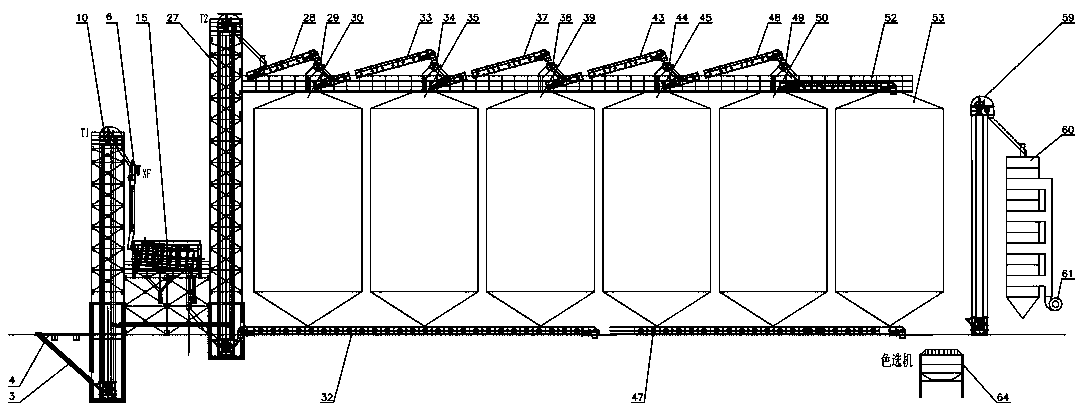

Environment-friendly automatic raw grain loading and unloading system

The invention relates to an environment-friendly automatic raw grain loading and unloading system. A hydraulic turnover plate is articulated with ground; a grain unloading pit is arranged below the right end of the hydraulic turnover plate; an elevator A is arranged on the right side of the grain unloading pit; a purification system is fixed on the right side of the elevator A; an elevator B is arranged on the right side of the purification system; the purification system is matched with a feed port below the elevator B; an allocation system is arranged on the right side of the elevator B; a belt conveyor L is arranged on the right side of the allocation system and matched with the allocation system; an elevator C is arranged on the right side of the belt conveyor L; the high end of the right side of the belt conveyor L is located above a feed port below the elevator C; a drying tower is arranged on the right side of the elevator C; a discharge port above the elevator C is communicatedwith a feed port above the drying tower; and a belt conveyor M is arranged below the drying tower. The system has the benefits that the system is large in loading and unloading volume; special dust collection equipment and dust and sundry discharge channel are adopted; and grains of different varieties and different grades are allocated to grains of required grades.

Owner:山东省巨野粮食储备库

Error tolerance and correction method for analysis of bar code identifiers of storage materials

ActiveCN102509200BImprove objectivityNo manual work requiredLogisticsSensing by electromagnetic radiationProgramming languageFault tolerance

The invention involves the field of warehousing material management. Specifically, it is a method of analysis of the warehousing material barcode identification. The following steps: step 1, collecting the storage material barcode data on the spot; step 2, the materials collected by the data collection are installedTransportation; step 3, data reading verification of barcode data collected by the current ERP program; step 4, call the embedded module to determine the information that reads the wrong code in step 3 to fault tolerance and correction.: Make warehousing materials out of the database data from complete collection and verification of post -after -to -after verifications without regional restrictions.The error code iteration operation is automatically called without artificial intervention. After the limited second iteration, the original code number corresponding to the original wrong code is restored to complete the automatic error correction method.Its iterative operations are operated by the module calls and data results by the program inside the program.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com