Wood chip automatic stacking machine

A stacking machine and automatic technology, applied in the direction of conveyor, object stacking, transportation and packaging, etc., can solve problems such as collapse, low stacking efficiency, and easy deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

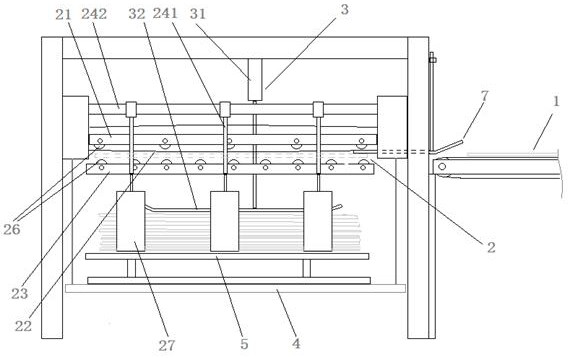

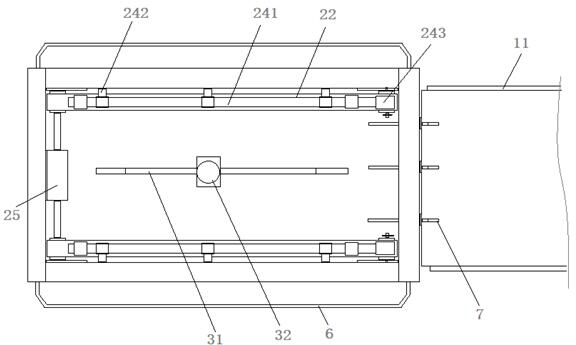

[0022] Such as figure 1 , figure 2 As shown, the present invention includes a material feeding channel 1 located at a high position and a material stacking device behind it. Ribs 11 are arranged on both sides of the material delivery channel 1. The material stacking device includes an edge clamping channel 2 and a pressing plate mechanism 3 installed on the frame. The blanking channel 2 is symmetrically installed in the same direction as the delivery channel, and the spacing is smaller than the width of the wood chips to be stacked, and is at the same height as the delivery channel 1. The blanking channel 2 includes an upper clamping piece 21, a conveyor belt 22, and a lower supporting piece 23 and the driving mechanism of the lower bracket, the frame is equipped with a biaxial extension motor 25, the output shafts at both ends of the biaxial extension motor 25 are respectively driven and connected to the conveyor belt 22 of the crimping and clamping road on both sides, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com