Environment-friendly automatic raw grain loading and unloading system

A loading and unloading system, environmentally friendly technology, applied in loading/unloading, transportation and packaging, etc., can solve the problems of inability to deploy, a large number of manual operations, and high work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

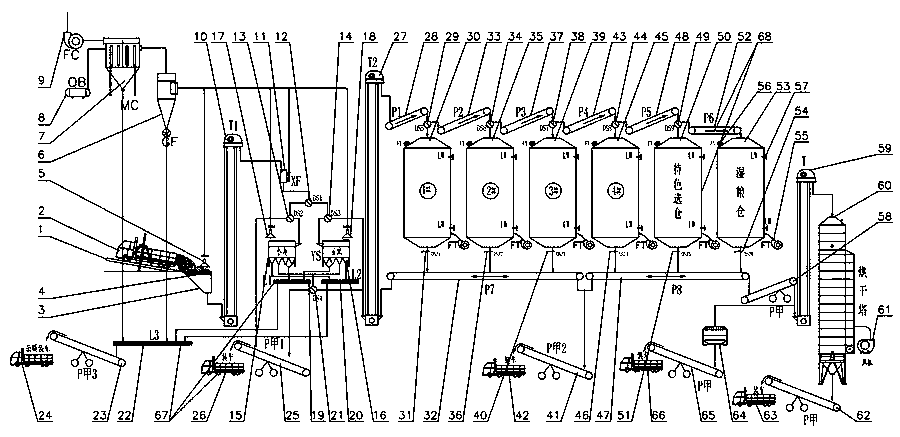

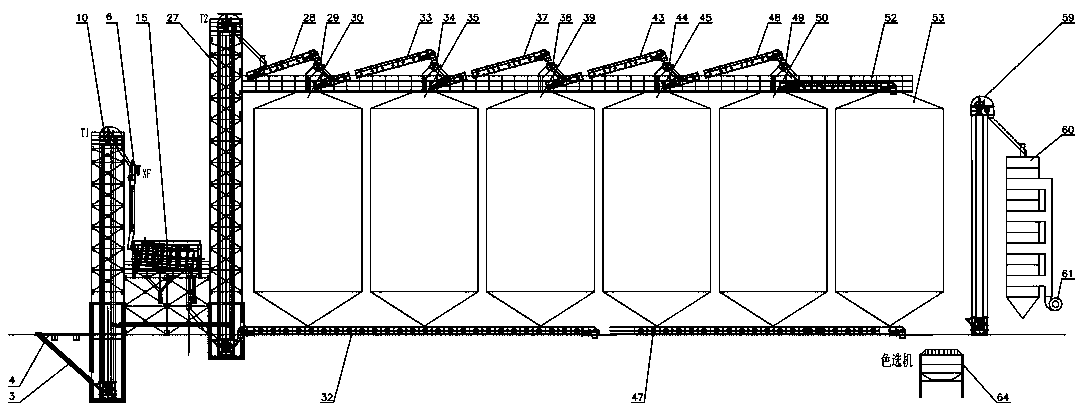

[0020] The embodiments of the present invention will be further described below in conjunction with the drawings.

[0021] Reference Figure 1-2 , The environmentally friendly raw grain automatic loading and unloading system described in this specific embodiment includes hydraulic flap 1, grain loading truck A2, grain unloading pit 3, elevator A10, elevator B27, belt conveyor L58, elevator C59, drying Dry tower 60, belt conveyor M62, grain loading truck D63, impurity removal system 67 and deployment system 68, hydraulic flap 1 is hinged to the ground, grain loading truck A2 is reversed to the upper surface of hydraulic flap 1, right end of said hydraulic flap 1 The grain unloading pit 3 is set below, and the right side of the grain unloading pit 3 is provided with a hoist A10, and the bottom of the grain unloading pit 3 is connected with the feed inlet at the bottom of the hoist A10, and the right side of the hoist A10 is fixedly connected to the impurity removal system 67, so T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com