Automatic feeding and discharging machining method for mobile phone middle frame with Z axis

A technology of automatic loading and unloading and mobile phone middle frame, which is applied in the field of automation, can solve problems such as difficulty in adapting to modern production, large number of mobile phone middle frames, missing and misplaced, etc., to reduce labor costs, save labor, and have good continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

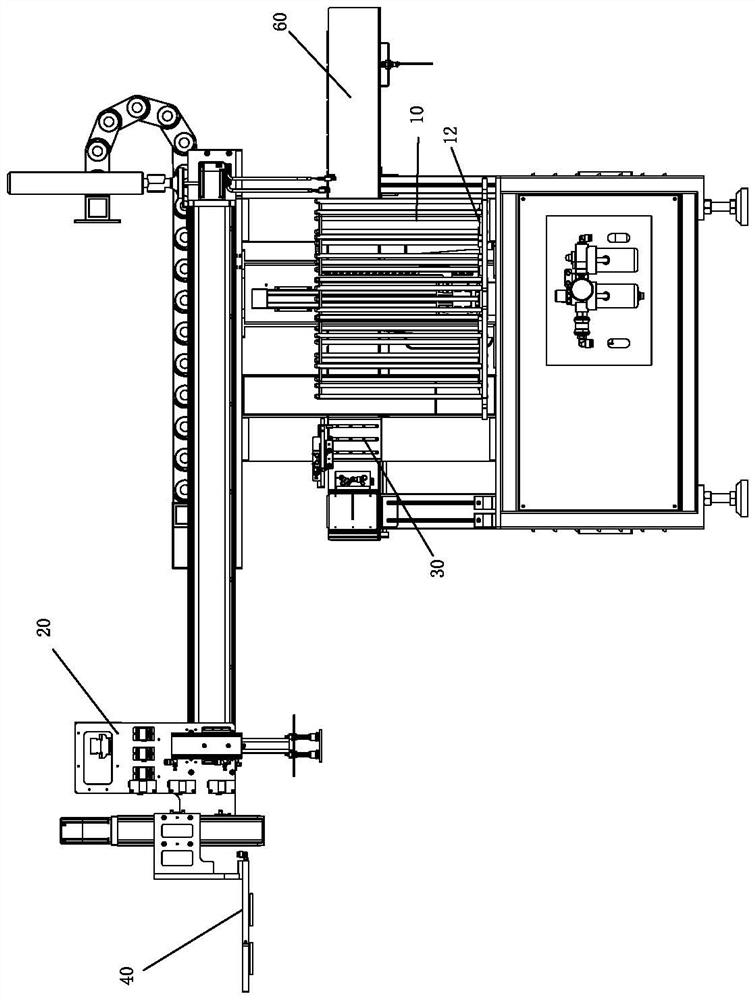

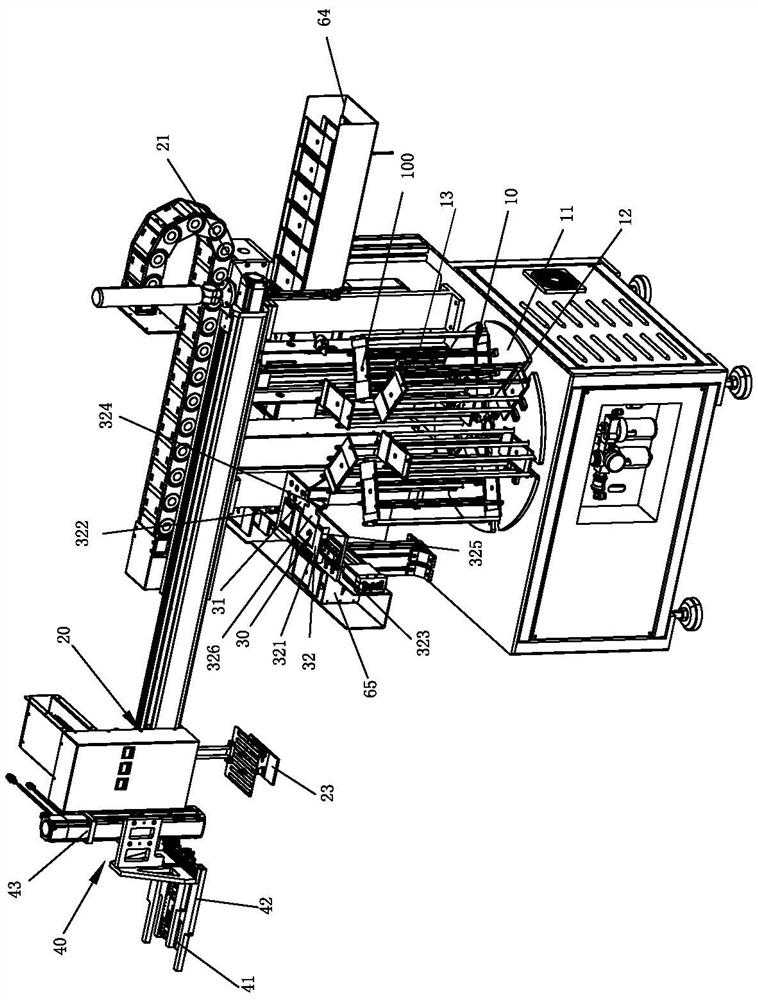

[0057] The invention describes an automatic loading and unloading processing method for the middle frame of a mobile phone with a Z axis, including the following steps

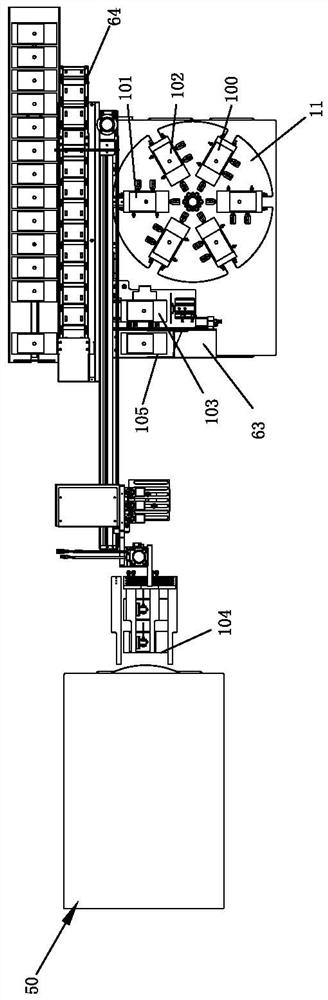

[0058] S1, put the board; stack the middle frame 100 of the mobile phone into 6 groups, each group has 50-100 pieces of the middle frame 100 of the mobile phone, each piece of the middle frame 100 of the mobile phone is stacked from bottom to top, and the surroundings of the middle frame 100 of each group are blocked and will not be scattered, and each group of mobile phone middle frames 100 is placed on the movable tray 12 of an aliquoter disc 11 to form a circle, the aliquoter disc 11 and the movable tray 11 located on the aliquoter disc 11 The tray 12 is driven to rotate intermittently, each rotation angle is 60 degrees; the rotation is triggered by the following conditions:

[0059]A lifting plate 14 is set below the movable tray 12, so that the lifting plate 14 is driven by the lifting motor 17 to rise st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com