Work fixture for grabbing injection parts of doll toy

A technology of tooling fixtures and injection molded parts, which is applied in the field of tooling fixtures for grabbing doll toy injection molded parts, and can solve the problems of hard work, high cost, and labor dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

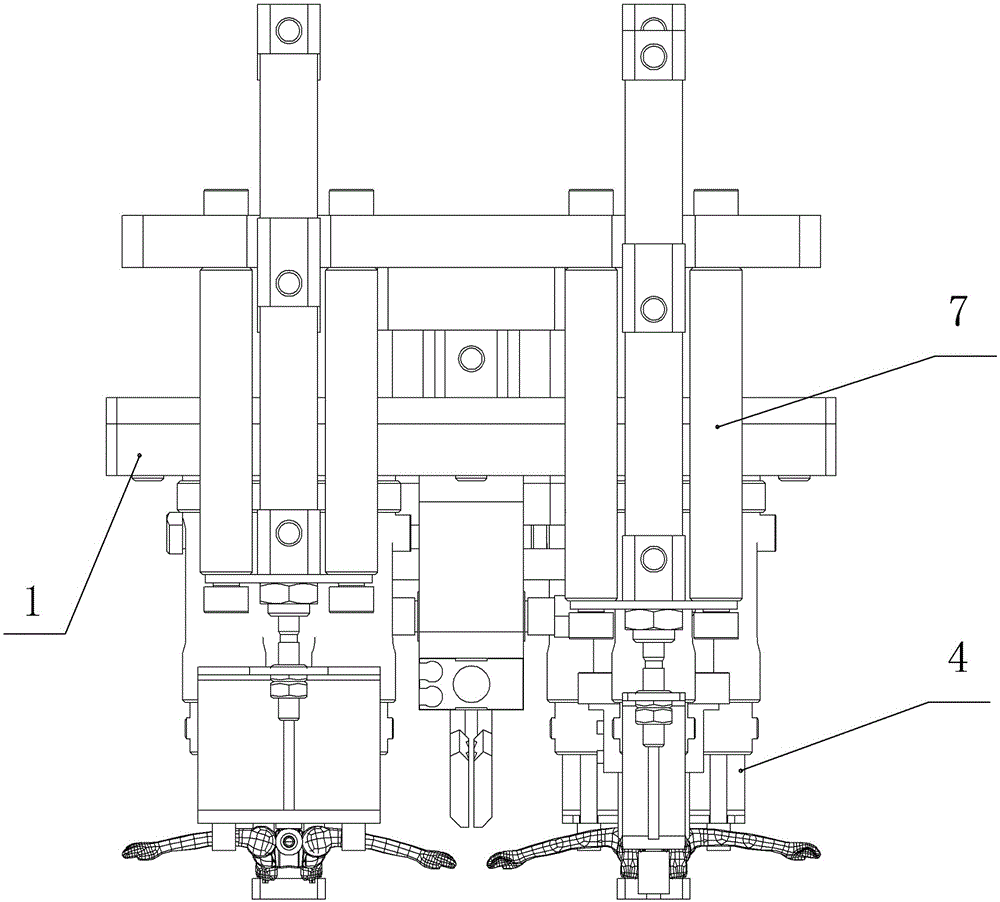

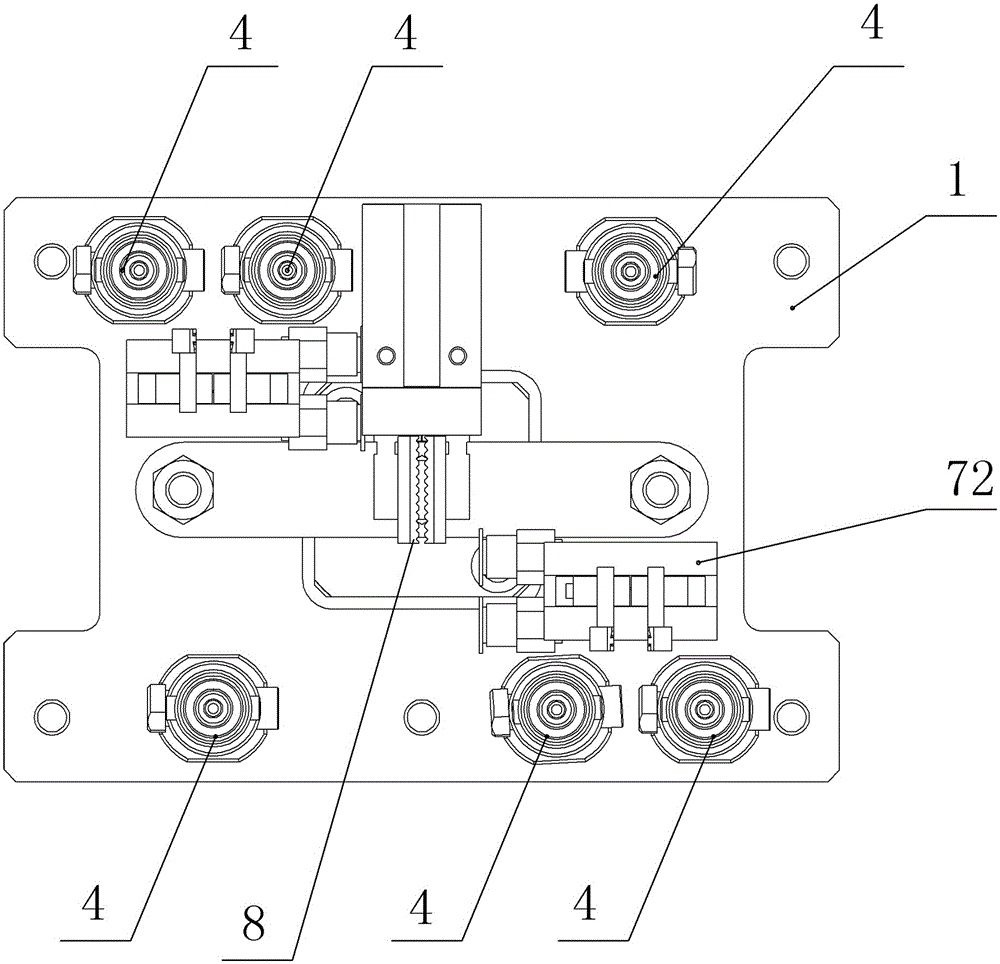

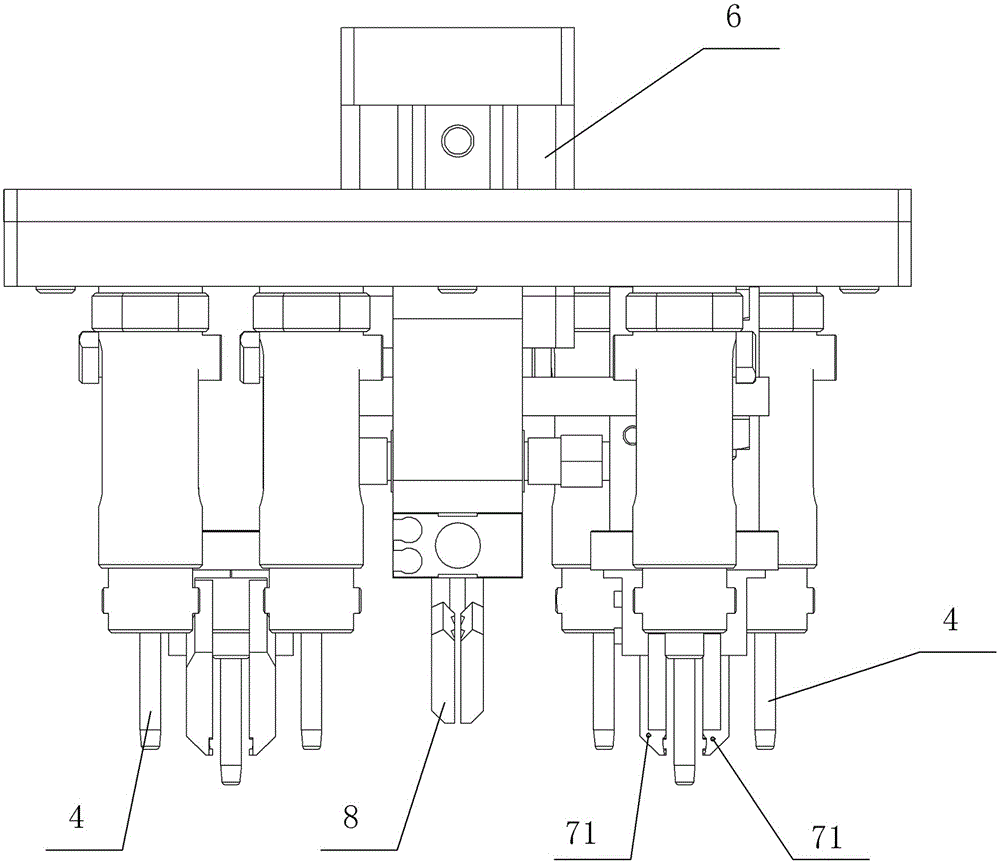

[0011] A tooling fixture for grabbing doll toy injection molded parts, including a mounting plate 1 installed on a robot manipulator and moving with the manipulator; the left and right arms and feet of the toy doll injection molded parts 10 are provided with drainage ports for discharging waste , and there is a tapered hole 3 on the drain; the mounting plate is equipped with a pin 4 inserted into the drain, and a drain 5 for discharging waste. The needle moves to insert or withdraw from the drainage cylinder 6, the drainage channel is connected with the drain port, and the waste discharged from the drain port is led out; the stripping mechanism 7 for clamping the toy doll injection molded parts when the toy doll injection molded parts are demoulded is also installed on the mounting plate , including clamping blocks 71 for clamping the injection molded parts of doll toys from left and right sides, and air claws 72 for driving the clamping blocks to move.

[0012] The drains of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com