Floating type unmanned bait casting boat

A bait-casting boat, floating technology, applied in the direction of unmanned surface ships, motor vehicles, ship construction, etc., can solve the problems of troublesome use and maintenance, complex structure and technology, high overall cost, etc., achieve light and compact mechanism, reduce production Cost, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present application will be described in detail below in conjunction with specific embodiments.

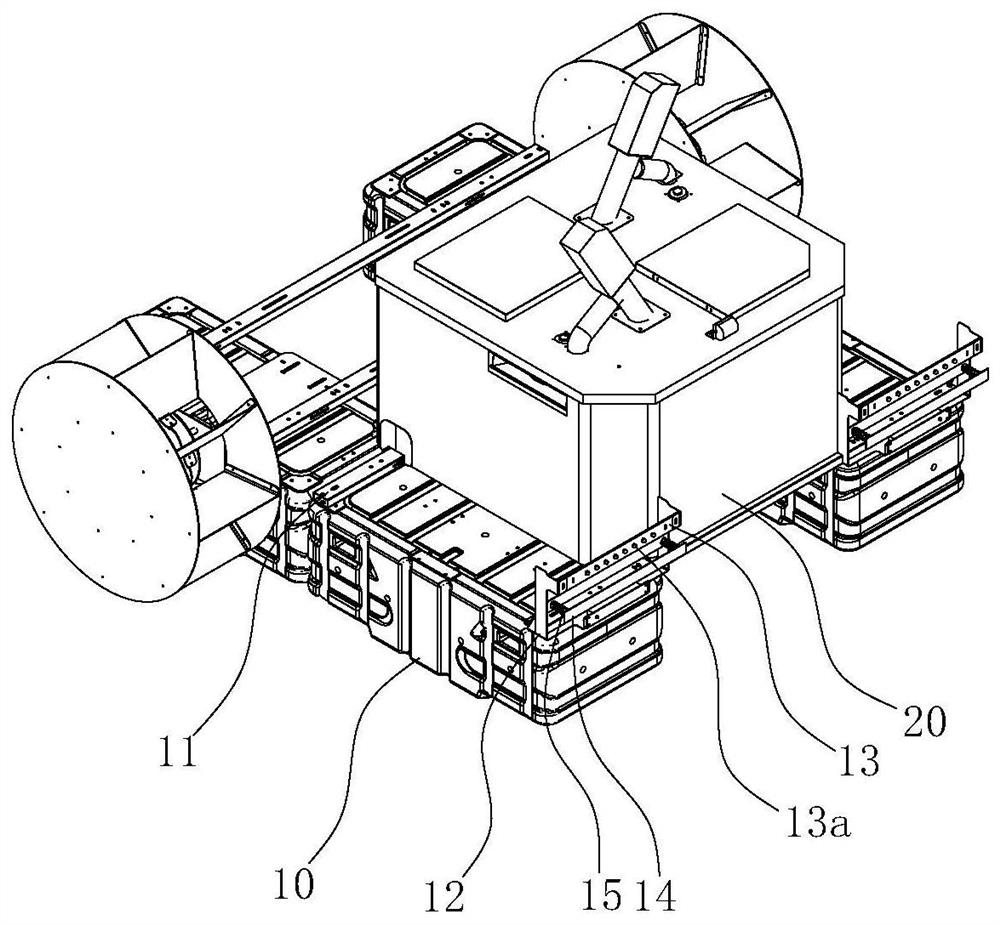

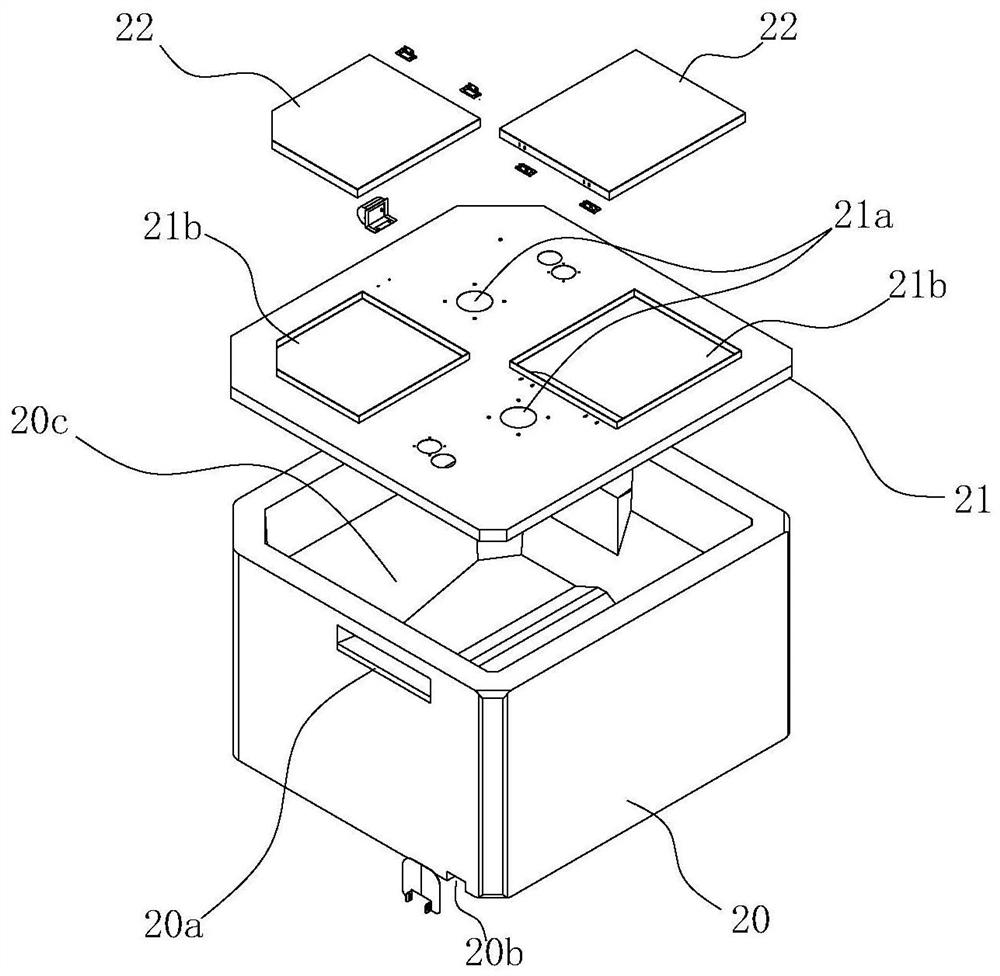

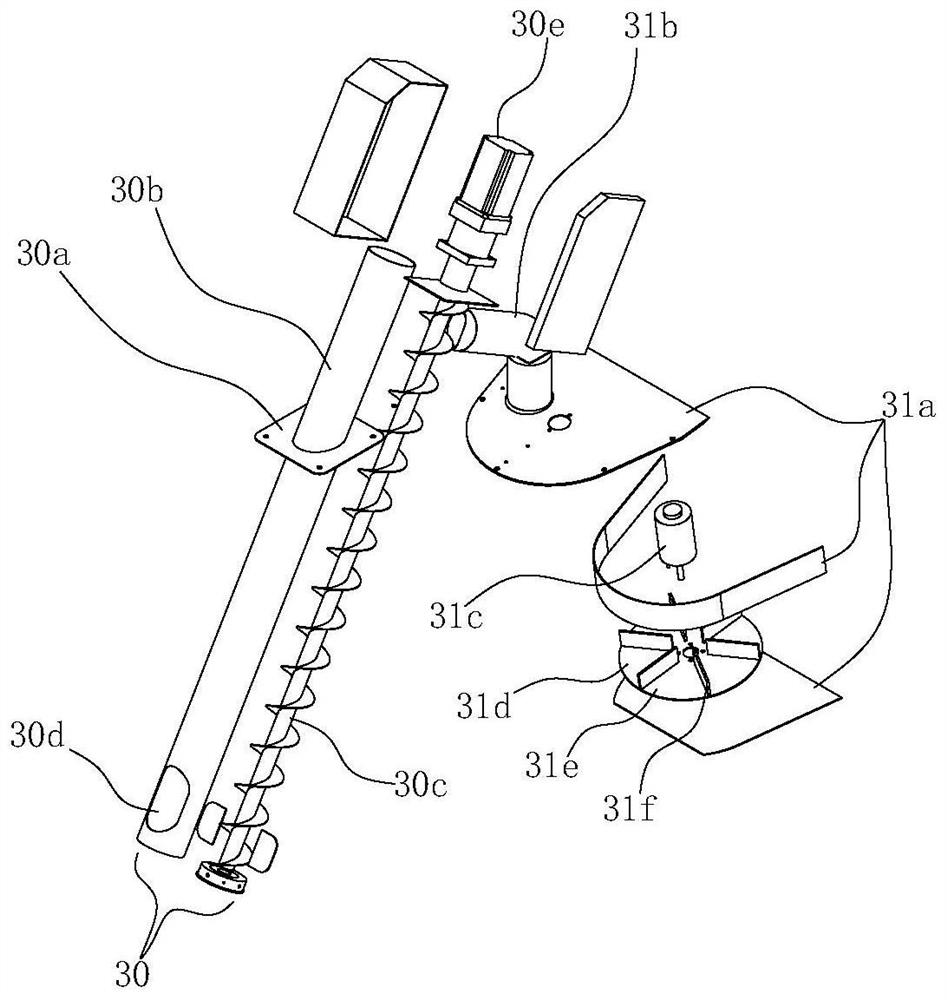

[0039] Such as figure 1 As shown, a floating unmanned bait-casting ship of the present application includes a hull assembly, a cabin assembly, and a throwing assembly;

[0040] The hull assembly includes: two floating body structures, a supporting structure connecting the two floating body structures, and a charging structure arranged on the rear side of the floating body structures. The floating body structure is composed of a plurality of floating bodies 10 spliced together. The structure includes a support frame 11 for connecting two floating body structures; the charging structure includes two charging brackets 12 fixedly arranged on the rear side of the attachment structure, and the rear side of the charging bracket 12 is provided with a charging contact plate 13 and a buffer plate 14 , the charging contact plate 13 is provided with a number of conductive contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com