Automatic green brick cutting-off machine for producing light refractory bricks

A technology of refractory bricks and billet cutting machines, applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of difficult to guarantee the size of finished products, difficulties, and easy deformation of mud strips, etc., to improve processing accuracy and product quality, The effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

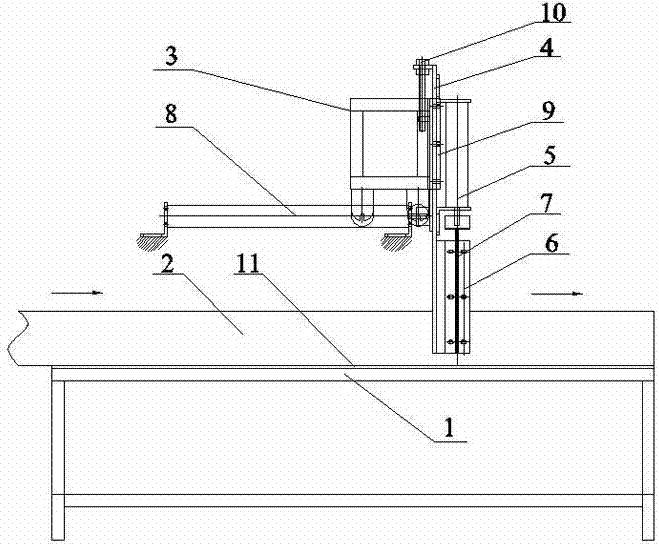

[0015] An automatic blank cutting machine for processing light refractory bricks, comprising a frame, a blank cutting table 1, a mud extruder and a PLC control system. The mud extruder is installed at one end of a horizontally arranged blank cutting table 1 and the blank is cut The table 1 is also provided with a backing plate 11, and the backing plate 11 is provided with a sliding rail. The mud stick 2 extruded by the mud extruder can continuously move along the sliding rail on the backing plate 11 on the top of the cutting table 1. The blank cutting table 1 is also provided with a trigger induction sensor for detecting whether there is a mud stick 2 passing above it, and the sensor is connected with the PLC control system;

[0016] The frame is set above the blank cutting table 1. A horizontal guide rail is fixed on the frame, and a mobile trolley 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com