Asphalt filling device for highway bridge maintenance

A technology for highway bridges and asphalt, applied in the field of asphalt filling devices for highway bridge maintenance, can solve the problems of wasting manpower, not setting up a corresponding warning mechanism, failing to play a warning role, etc., achieving good warning reminders, improving reinforcement effects, and saving human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

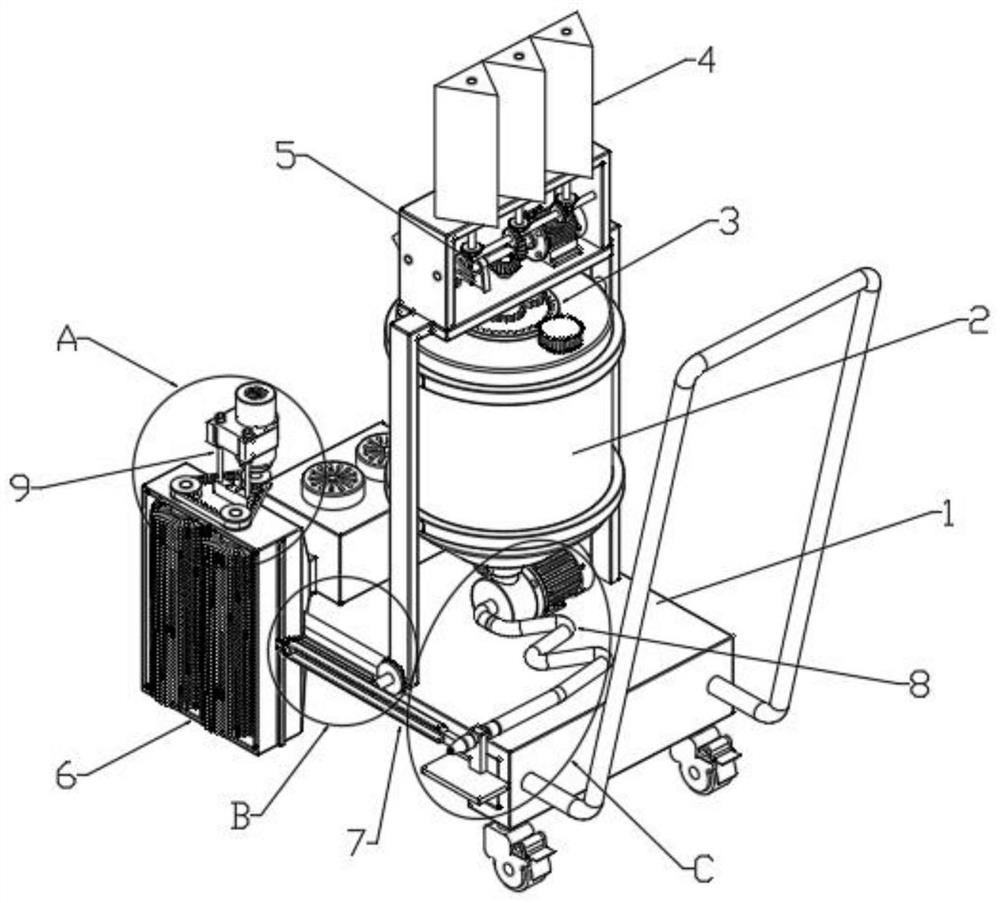

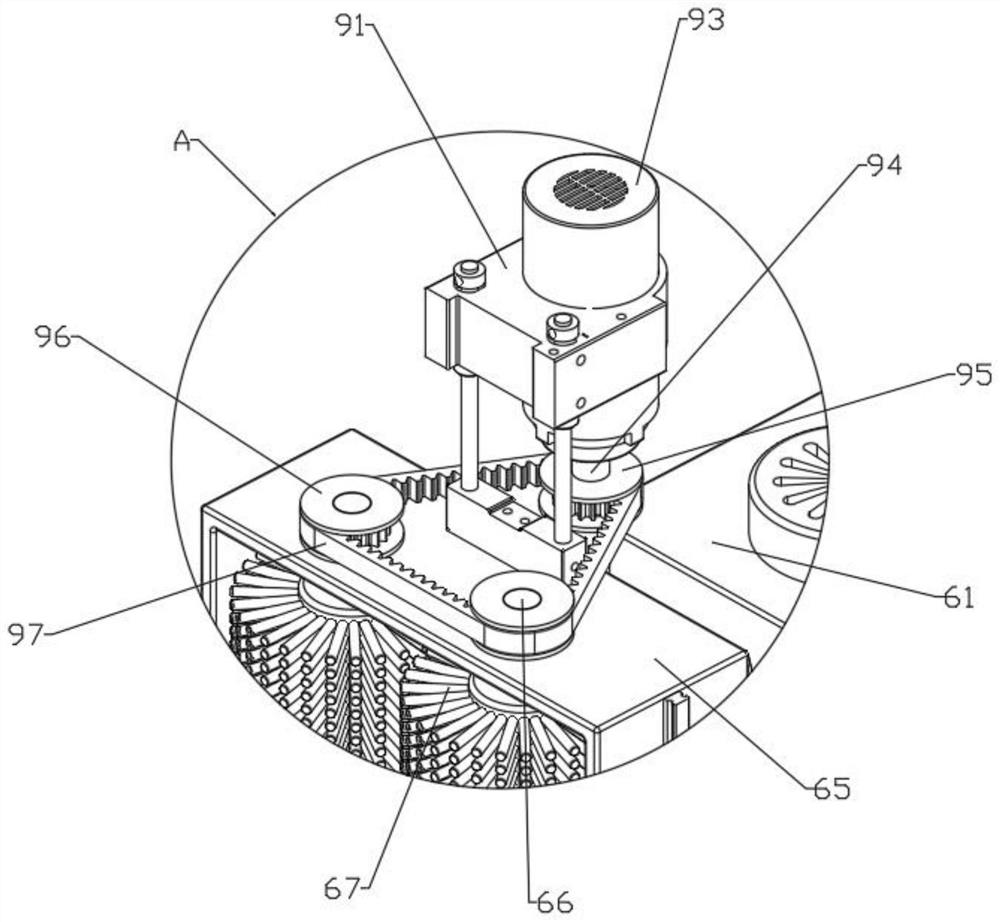

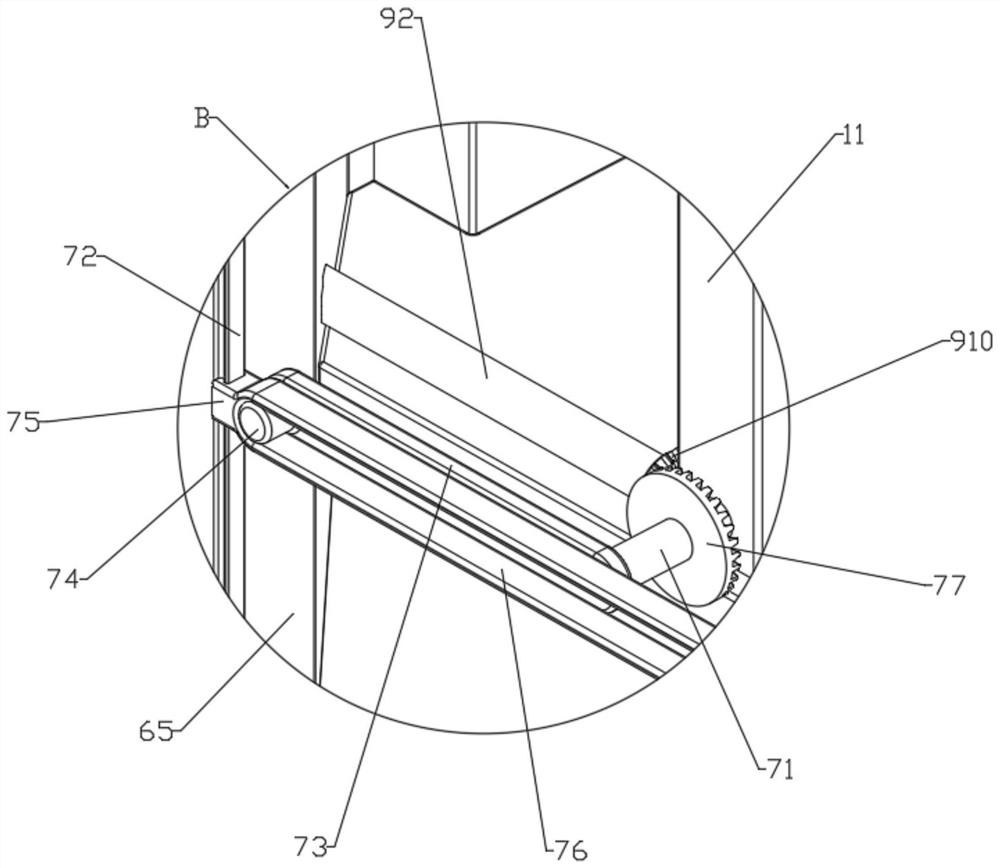

[0031] Example: as Figure 1-9 As shown, the present invention provides an asphalt filling device for highway bridge maintenance, including a mobile frame 1, a U-shaped frame 11 is fixedly installed on the mobile frame 1, and a stirring device is rotatably installed on the inner side of the U-shaped frame 11 The barrel 2, the mixing barrel 2 is provided with a corresponding heating mechanism, so that the solid asphalt can be melted, which is the prior art, and will not be repeated here. The inner side of the U-shaped frame 11 is fixedly installed with symmetrically arranged Side posts 12, U-shaped collars 13 are fixedly installed between the side posts 12, two sets of annular swivels 14 are fixedly sleeved on the mixing barrel 2, and the annular swivels 14 are rotatably inserted into the U-shaped sleeves In the ring 13, the U-shaped collar 13 and the annular swivel 14 are used together to provide a guarantee for the normal rotation adjustment of the mixing barrel 2. The end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com