Sensor apparatus for vehicle

A sensor device and sensor technology, applied in the direction of vehicle design optimization, vehicle components, vehicle safety arrangements, etc., can solve the problems of increasing assembly time, increasing the number of components and assembly processes, and assembly tolerances, so as to simplify the assembly process and eliminate assembly tolerances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, a sensor device for a vehicle according to an embodiment of the present disclosure will be described in detail with reference to the accompanying drawings. It should be noted that the drawings are not drawn to precise scale and may be exaggerated in thickness of lines or size of components for convenience and clarity of description only. Also, the terms as used herein are defined by considering the functions of the present disclosure, and may be changed according to user's or operator's habit or intention. Therefore, definitions of terms should be made according to the overall disclosure set forth herein.

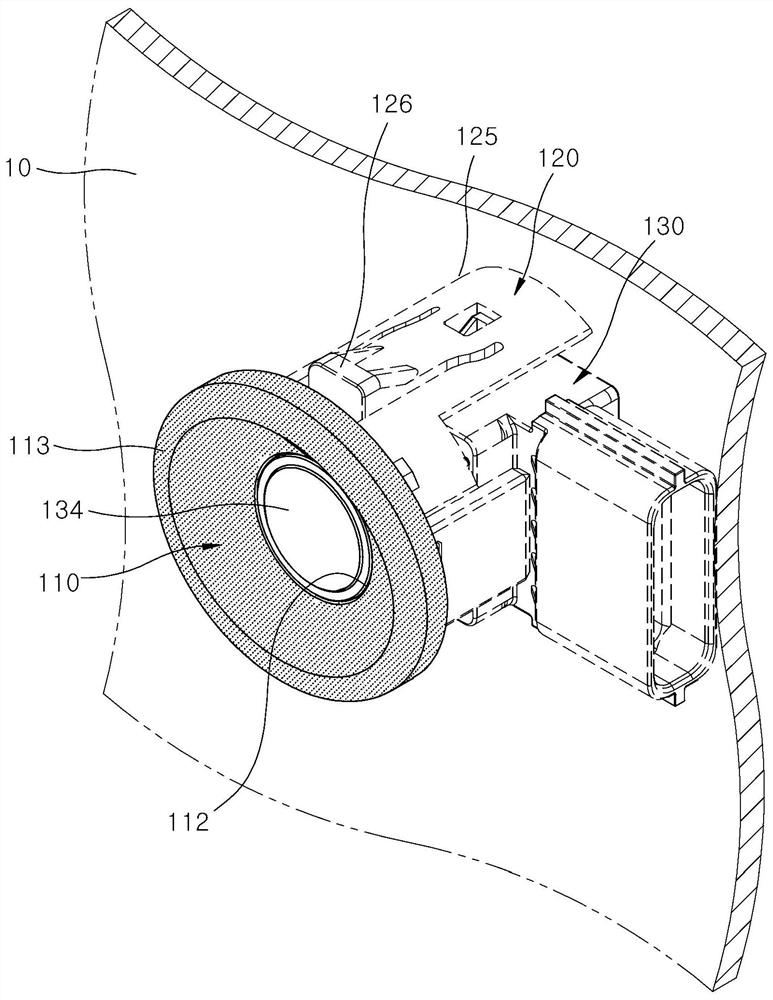

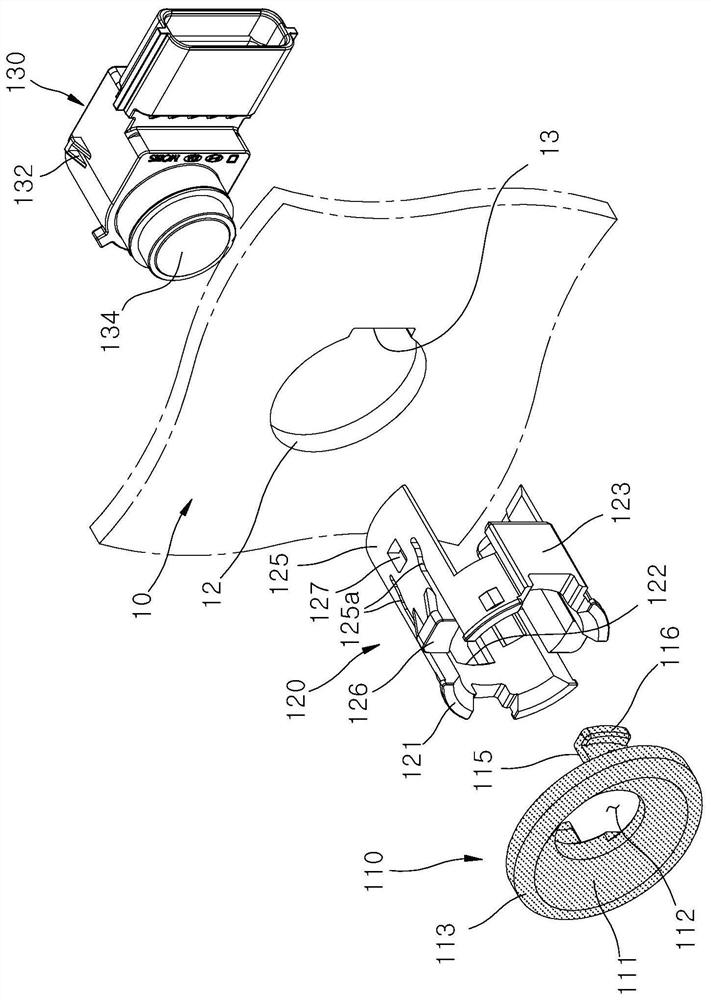

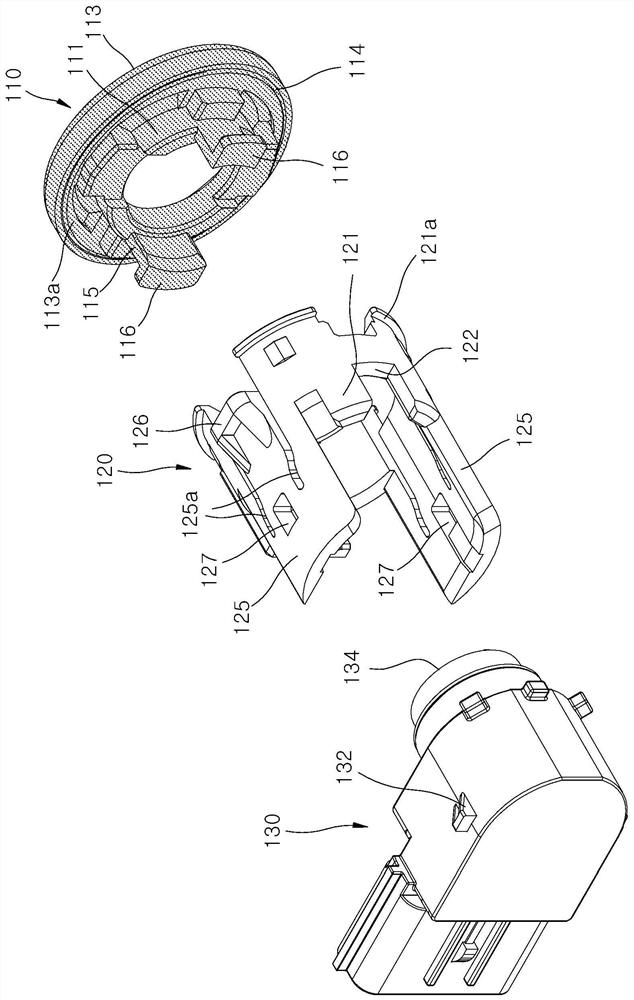

[0036] figure 1 is a perspective view showing that a sensor device for a vehicle according to an embodiment of the present disclosure is installed in a floor, figure 2 is an exploded perspective view showing a position where the sensor device for a vehicle according to the embodiment of the present disclosure is inserted into the floor, image 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com