Assembly type dry hanging structure for resin plate modeling design and method

A resin board and assembled technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of non-adjustment in the later stage of installation, problems in the installation process, and cumbersome installation procedures, etc., to achieve popular construction, fast installation height, and The effect of labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

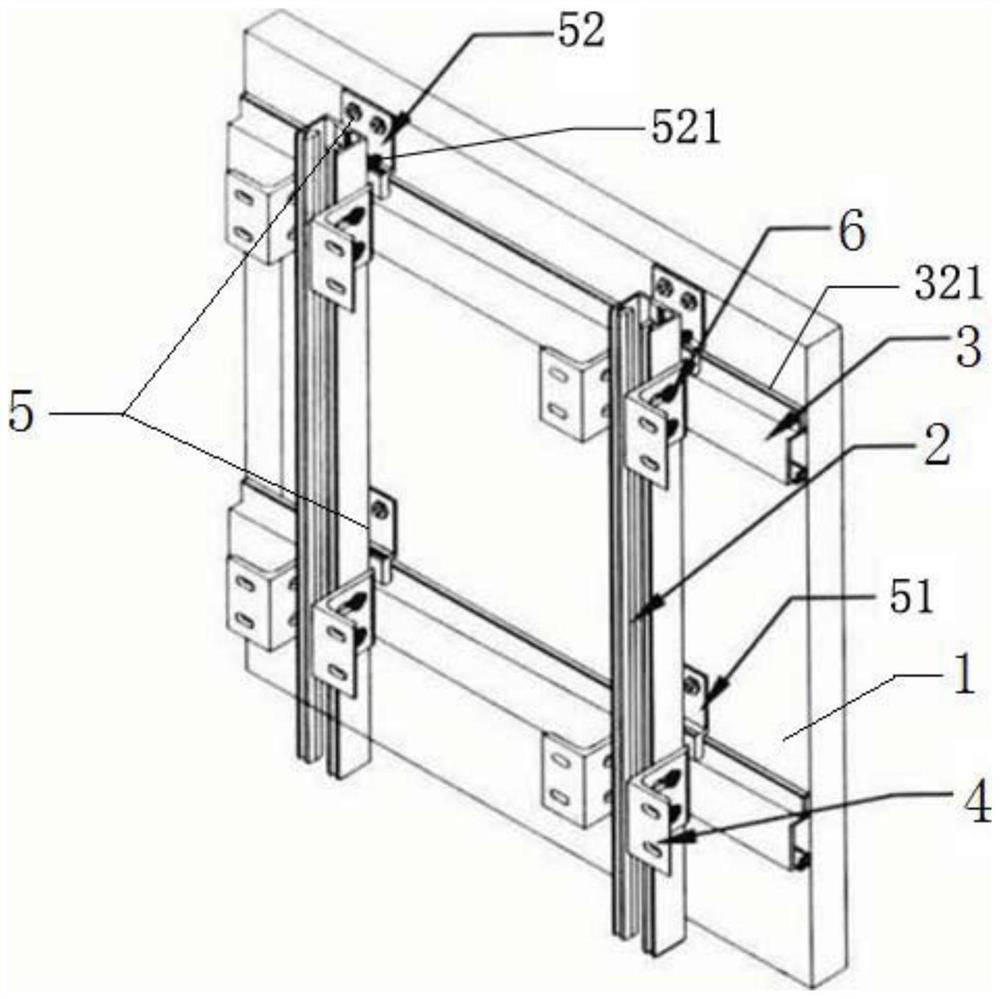

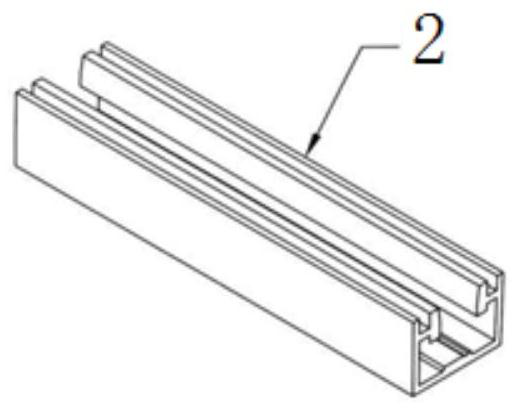

[0031] see figure 1 , the figure shows a prefabricated dry-hanging structure of a resin plate design provided by Embodiment 1 of the present invention, mainly including: a resin plate 1; vertical keels 2, which are arranged side by side in pairs along the vertical direction; 3. It is arranged side by side in pairs along the horizontal direction, and the horizontal keel 3 is connected to the vertical keel 2 to form an overall keel frame; the adjustable base 4 is connected to the vertical keel 2 and the base of the wall; the dry hanging piece 5 is set on the resin board 1, and is connected with the transverse keel 3.

[0032] An assembled dry-hanging structure designed with a resin plate shape provided in this embodiment mainly includes a resin plate 1, a vertical keel 2, a transverse keel 3, an adjustable base 4 and a dry hanging piece 5, and the vertical keel 2 can be adjusted by The base 4 is connected to the base of the wall, the horizontal keel 3 is connected to the vertic...

Embodiment 2

[0047] see figure 1 , Figure 4 , the figure shows a prefabricated dry-hanging structure of a resin plate design provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The adjustable base 4 is "L"-shaped, on which an adjustment hole 41 is arranged, and the length direction of the adjustment hole 41 is perpendicular to the vertical keel 2; It is connected with the vertical keel 2; the fastener 6 is an expansion screw or an expansion bolt, wherein the adjustment hole 41 is a round hole. Through the setting of the above-mentioned structure and the setting of the adjustment hole 41, the connection position between the adjustable base 4 and the base of the wall and the vertical keel 2 can be changed, so as to change the position of the vertical keel 2 on the base of the wall, up and down, left and right, achieve a leveling effect.

Embodiment 3

[0049] see Figure 1 to Figure 6 , the figure shows a prefabricated dry-hanging structure of a resin plate design provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The dry hanger 5 includes a fixed dry hanger 51 and an adjustable dry hanger 52 respectively located at the bottom and top of the resin board 1; both the fixed dry hanger 51 and the adjustable dry hanger 52 are in a "Z" shape; the main body of the fixed dry hanger 51 is connected to the resin plate 1, the main body of the fixed dry hanger 51 has a first L-shaped articulated plate 511 articulated with the transverse keel 3 .

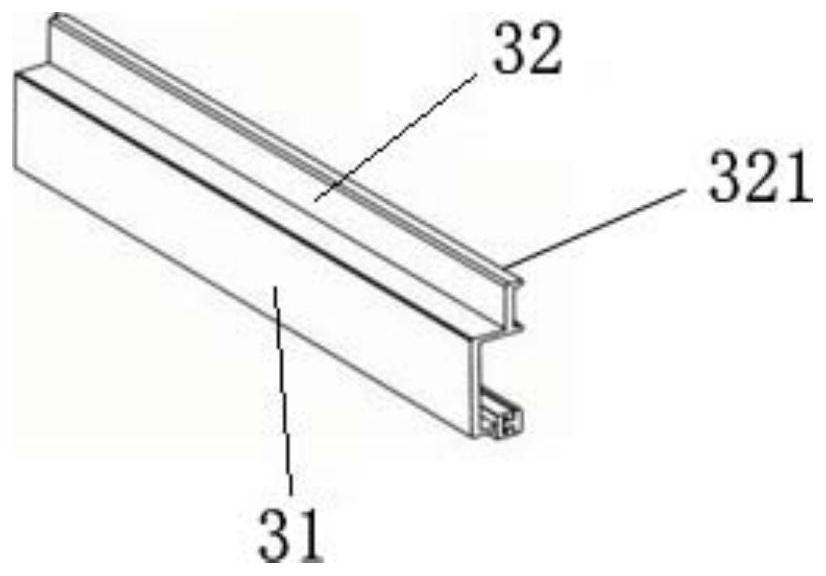

[0050] The side of the vertical keel 2 is U-shaped; the horizontal keel 3 is a special-shaped keel, which includes a connecting keel 31 and a hanging keel 32, the connecting keel 31 is connected with the vertical keel 2, and the hanging keel 32 is hung with the dry h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com