High-capacity dosing fuel injection valve with inductive circuit

A technology of fuel injection valve and inductive circuit, which is applied to fuel injection devices, special fuel injection devices, charging systems, etc., can solve the problems of nozzle leakage and spray quality, valve seat pitting, reducing material fatigue strength, etc., to ensure fuel efficiency. Injection quality, good static sealing ability, and the effect of preventing fatigue deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

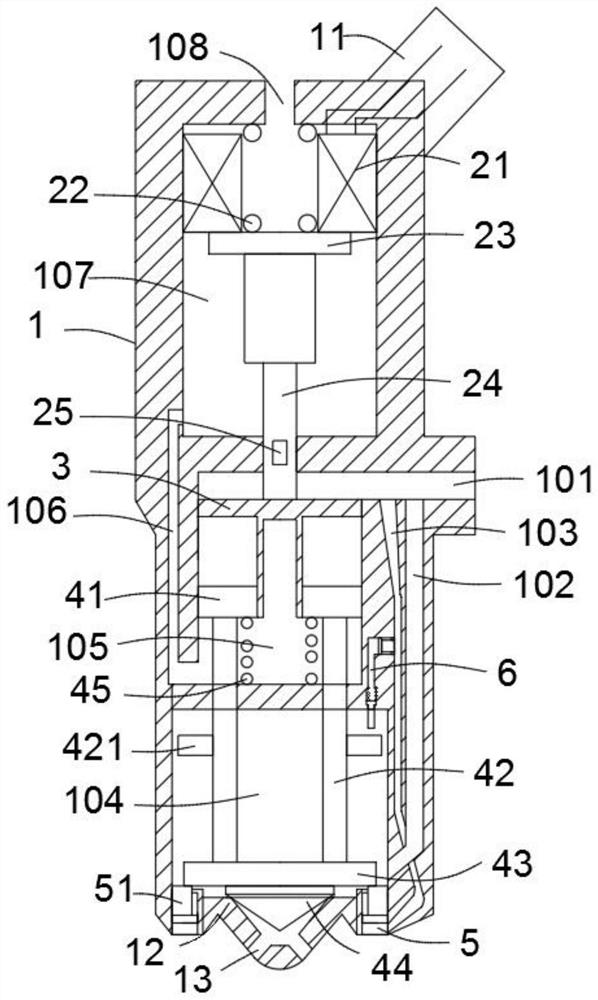

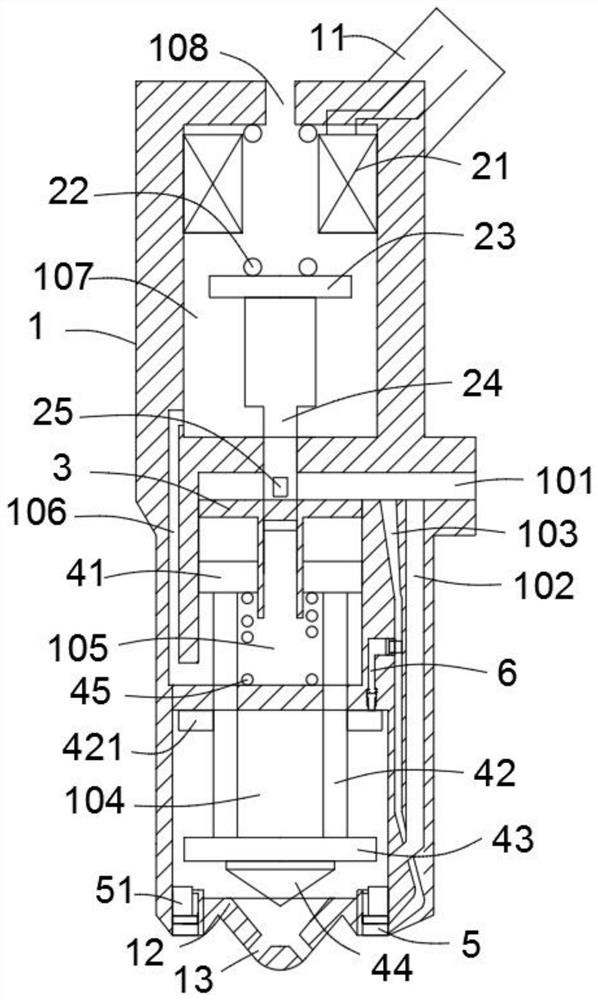

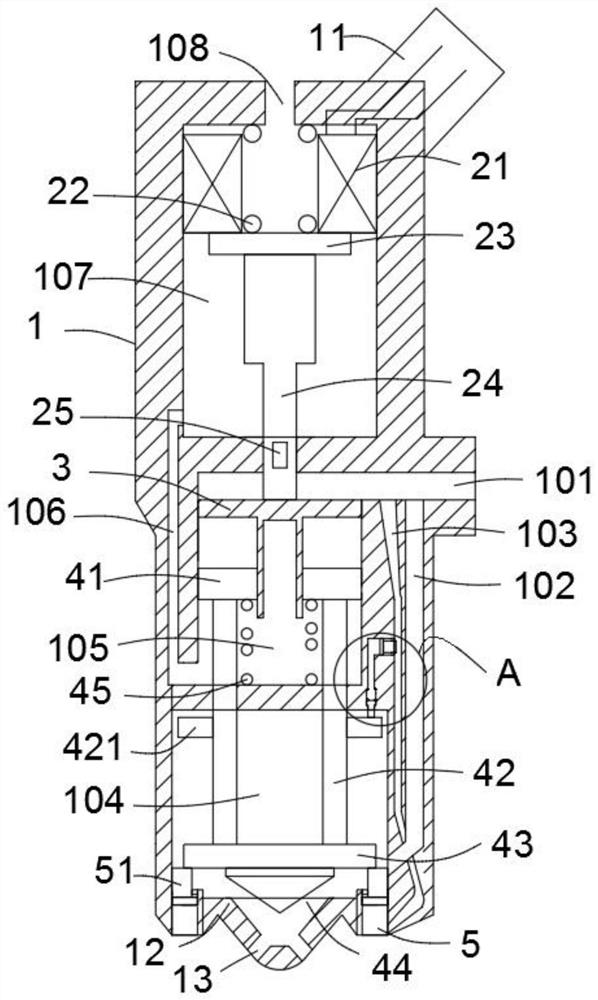

[0036] Example: such as Figure 1~6 As shown, the high-capacity quantitative fuel injection valve with an inductance circuit includes a valve body 1, and the interior of the valve body 1 is provided with an armature chamber 107, a high-pressure channel 101, a pressurized chamber 105 and a storage chamber 104 from top to bottom, The high-pressure passage 101 and the storage chamber 104 are connected through the storage chamber passage 102, and the armature chamber 107 is provided with an electromagnetic component that controls the conduction or closure between the high-pressure passage 101 and the pressurization chamber 105. The storage chamber 104 and the charging chamber The pressure chamber 105 is separated, and the material storage chamber 104 and the pressurization chamber 105 are provided with a valve plug part that is separated / bonded with the valve seat 12 according to the pressure change in the material storage chamber 104. The valve seat 12 is provided with a spray hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com