Flexible eyewear assembly

A technology of glasses components and flexible components, which is applied in the direction of lens components, glasses/safety glasses, glasses/goggles, etc., and can solve problems such as assembly complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

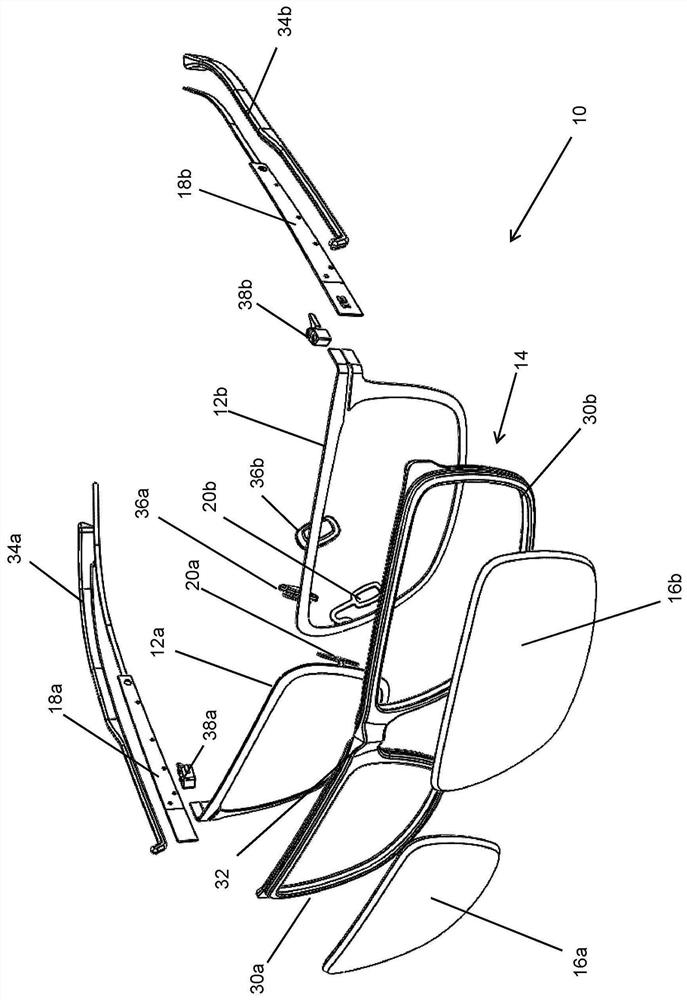

[0021] To provide flexibility in spectacles such as eyepieces, the rigid frame parts separated at the nose can be held together by a flexible part that is either overmolded for the two position openings of the spectacle lens in place or It is otherwise attached to the rigid frame portion and provides the flexibility of the glasses at the mid-nose area. The flexible part may be provided along the inner edge of the rigid frame part and includes a lens holder which holds the spectacle lens in the lens holder.

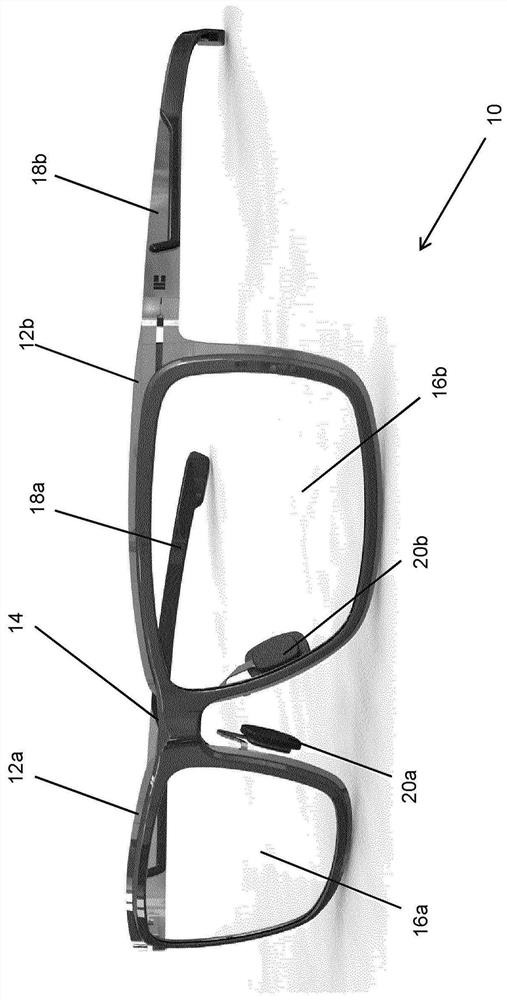

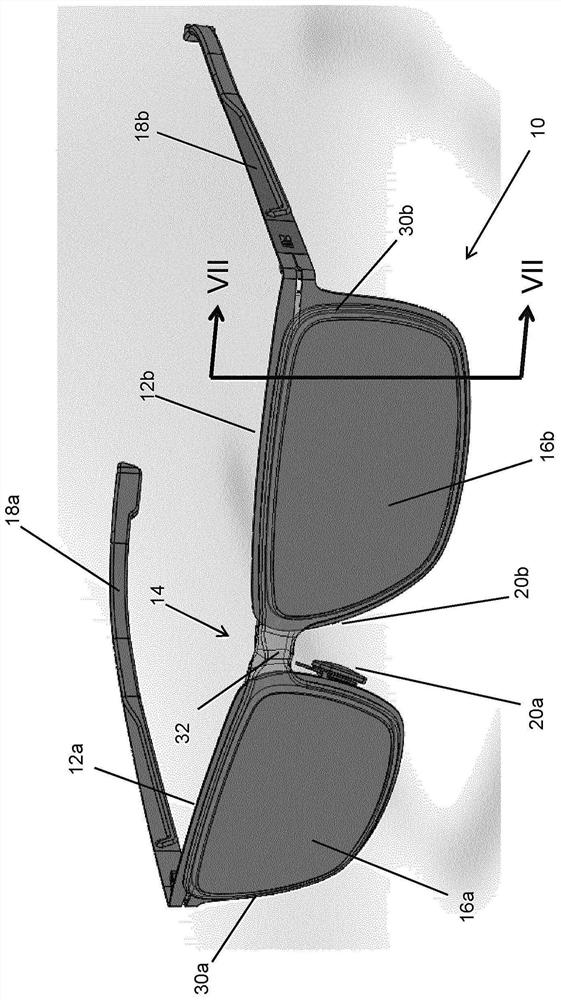

[0022] Now turning to the attached image, figure 1 A perspective view of assembled eyeglasses 10 is provided, also interchangeably referred to herein as eyeglass assembly 10 or eyeglasses 10 for the sake of brevity. Eyeglasses 10 include a pair of separate rigid frame portions 12, in this example, a first rigid frame portion 12a and a second rigid frame portion 12b. The first arm 18a is connected to the first rigid frame part 12a, and the second arm 18b is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com