Grinding device for four sides of wooden pigeon nest box assembly plate

A technology for assembling boards and nest boxes, which is applied to grinding drives, grinders, abrasive belt grinders, etc., can solve the problems of worker injury and low safety, and achieve the effect of avoiding injury and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

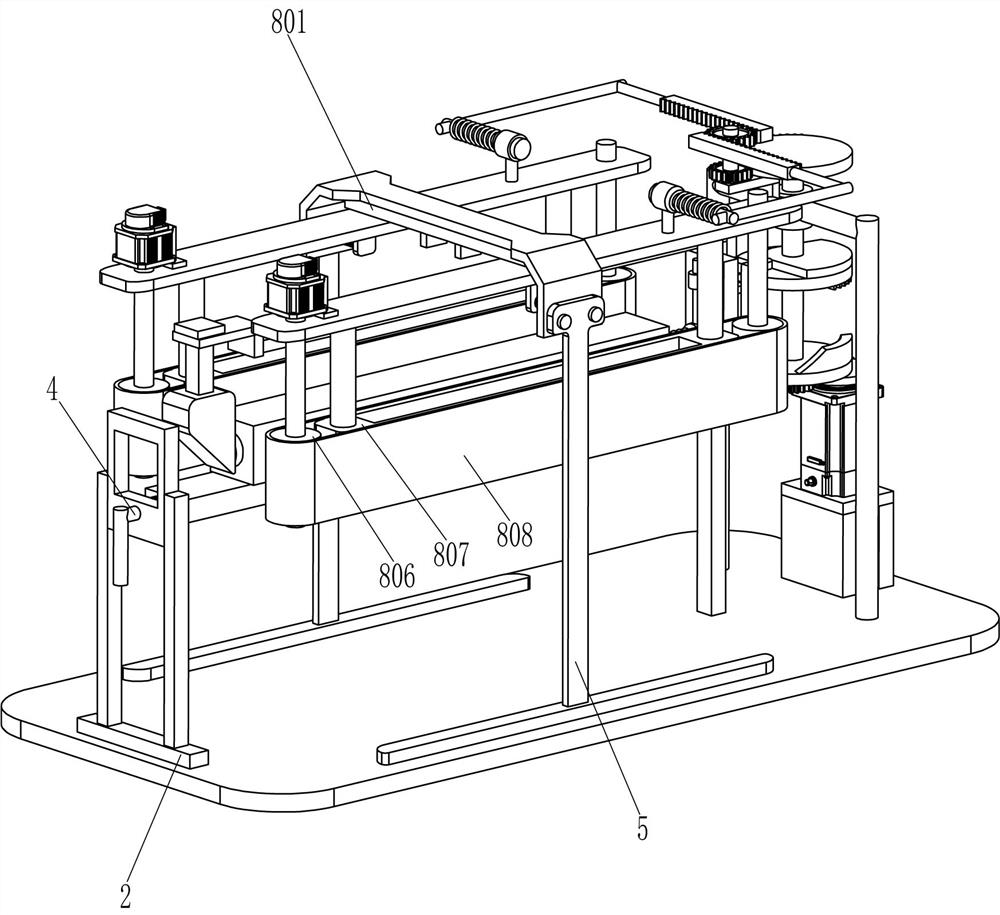

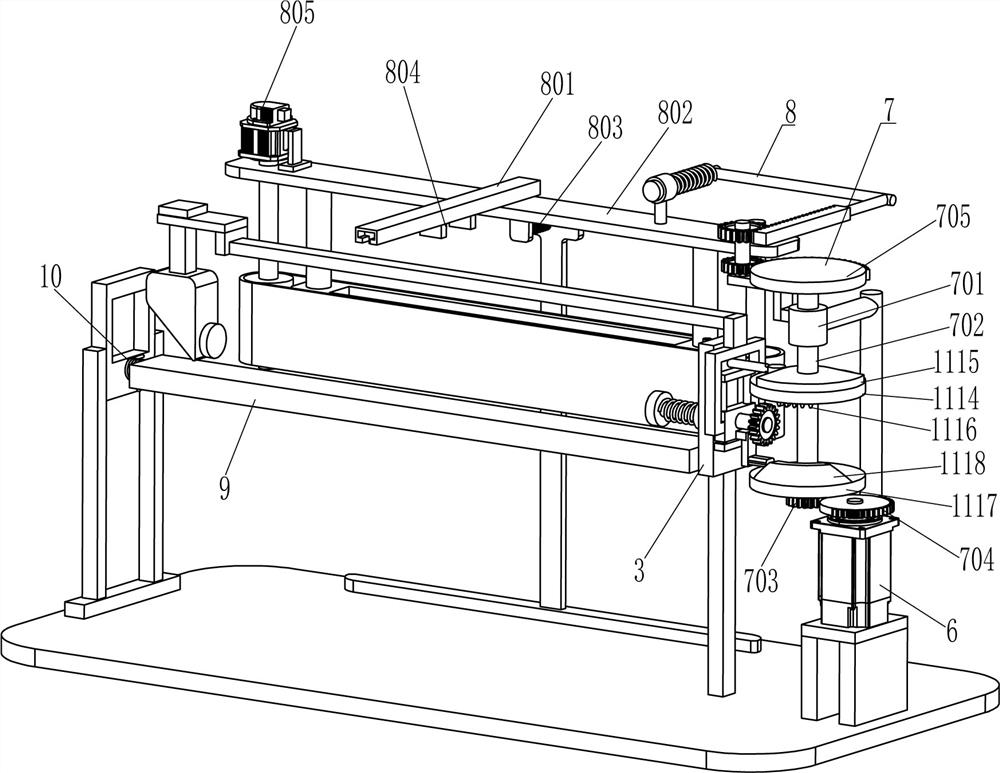

[0024] A kind of four-side grinding device for wooden pigeonhole box assembly board, such as Figure 1-5 As shown, it includes a bottom plate 1, a first support frame 2, a second support frame 3, a rotating rod 4, a frame 5, a servo motor 6, a fitting component 7, a grinding component 8, a placement plate 9 and a torsion spring 10, the bottom plate 1 The first support frame 2 is installed on the left side of the top by bolts, the second support frame 3 and the servo motor 6 are installed on the top right side of the bottom plate 1 by bolts, the servo motor 6 is located on the right side of the second support frame 3, and the first support frame 2 The upper part is rotatably equipped with a rotating rod 4, and the right end of the rotating rod 4 is connected with a placing plate 9, and the placing plate 9 is connected with the second support frame 3 in a rotating manner through a bearing seat, and a torsion spring is connected between the placing plate 9 and the first support fr...

Embodiment 2

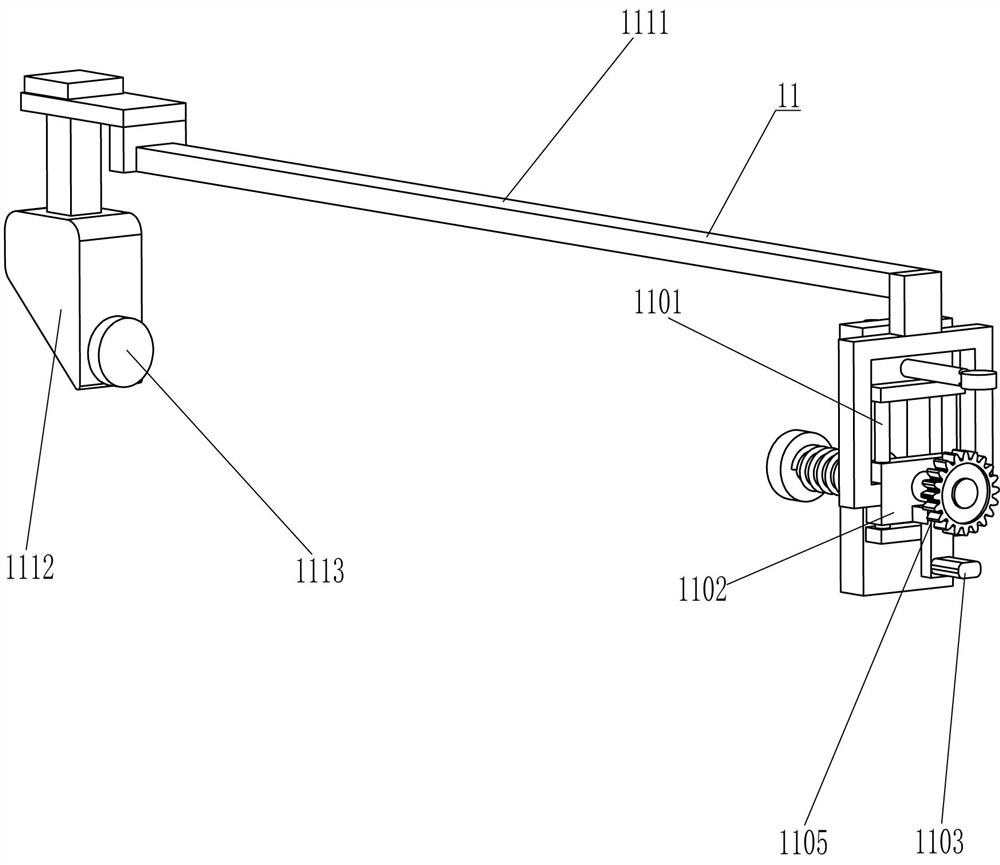

[0031] On the basis of Example 1, such as Figure 4-7 As shown, it also includes an overturn assembly 11, and the overturn assembly 11 includes a slide bar 1101, a slider 1102, a contact block 1103, a third rotating shaft 1104, a fourth gear 1105, a limit ring 1106, a connecting ring 1107, and a third elastic member 1108, sliding sleeve 1109, contact rod 1110, third support frame 1111, first wedge block 1112, rotary pressing block 1113, first turntable 1114, cam 1115, ring rack 1116, second turntable 1117 and arc wedge block 1118 , the right side of the second support frame 3 is equipped with a slide bar 1101 through bolts, a slide block 1102 is slidably arranged on the slide bar 1101, a contact block 1103 is connected to the right side of the slide block 1102, and a third rotating shaft is slid inside the slide block 1102 1104, a fourth gear 1105 is installed on the right end of the third rotating shaft 1104, a limit ring 1106 is installed on the outside of the third rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com