Blind Hole Embedded Part and Its Construction Method

A construction method and technology for embedded parts, which can be applied to buildings and building structures, etc., can solve the problems of blind hole embedded parts being easily damaged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

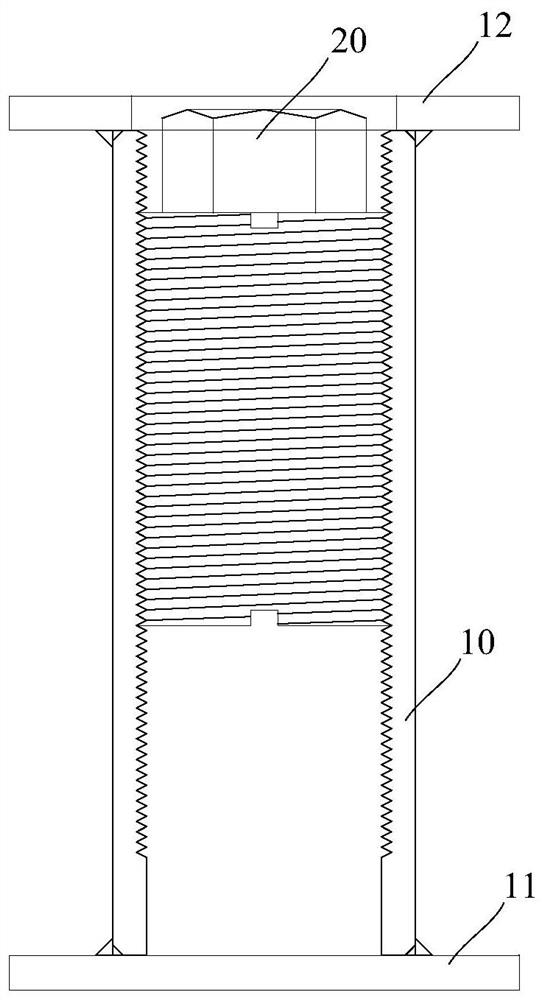

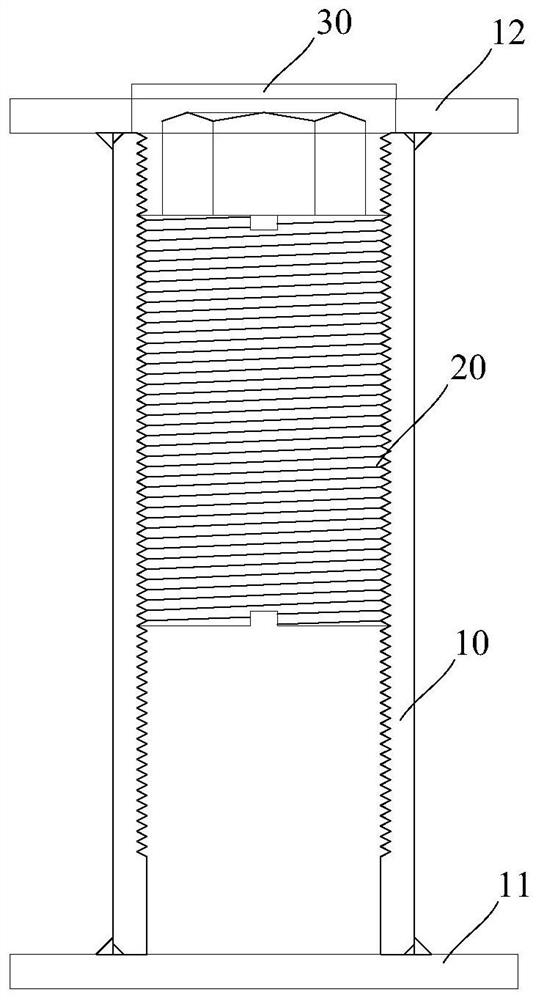

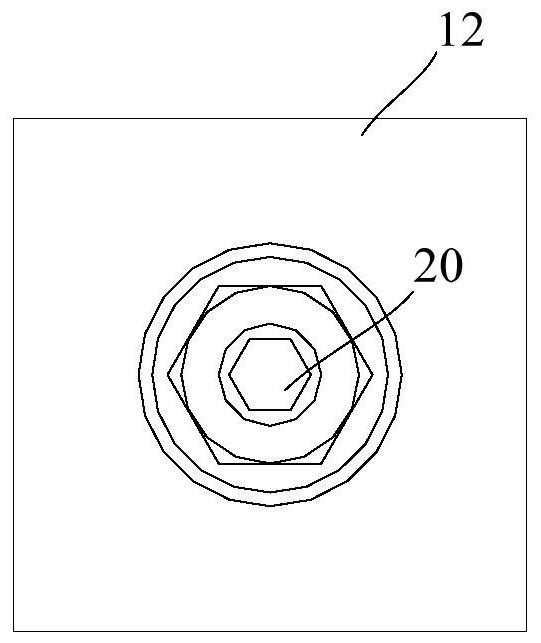

[0029] refer to figure 1 , shows the elevation view of the blind hole embedded part of the present invention. figure 2 It is a plan view of the blind hole embedded part of the present invention. combine figure 1 and figure 2 As shown, the blind hole embedded parts of the present invention include:

[0030] The pipe body 10 pre-embedded in the concrete structure, the interior of the pipe body 10 is hollow and penetrates up and down, and the inner wall of the pipe body 10 is formed with internal threads;

[0031] bolts 20 screwed into the pipe body 10; and

[0032] The filling material in liquid state is filled in the gap between the pipe body 10 and the bolt 20 , and is solidified into a filling layer 30 that blocks the gap between the pipe body 10 and the bolt 20 and covers the top of the bolt 20 .

[0033] As a preferred embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com