Hydrophilic normal-temperature rolling liquid

A normal temperature rolling and hydrophilic technology, applied in the field of rolling fluid and hydrophilic normal temperature rolling fluid, can solve the problems of increased cost and waste liquid discharge, explosion in the production environment, and inhalation of operators, so as to reduce Effects of water treatment costs, saving water treatment costs, and reducing waste discharge

Active Publication Date: 2021-07-27

郭圣倾

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006]3. When the rolling oil becomes an emulsion, it is heated to form oil mist. The production environment is very harsh and is easily inhaled by the operators, and the production environment is explosive danger;

[0007]4. The rolling oil is an oily product. There are oil stains on the steel plate after rolling. The subsequent process needs to be degreased and cleaned, which increases the cost and discharge of waste liquid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

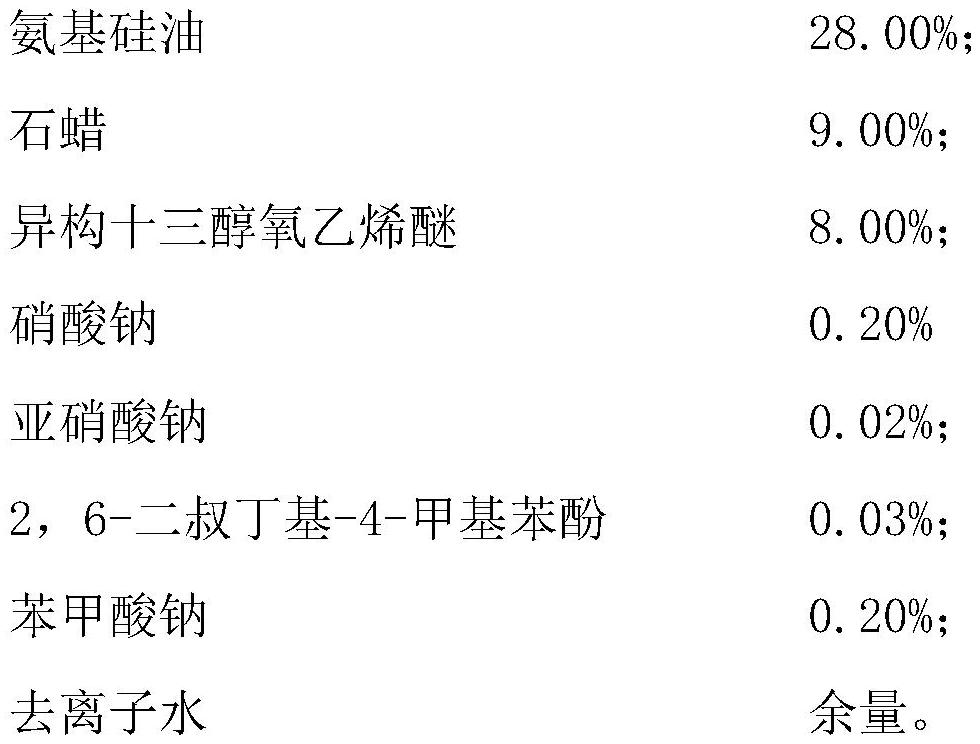

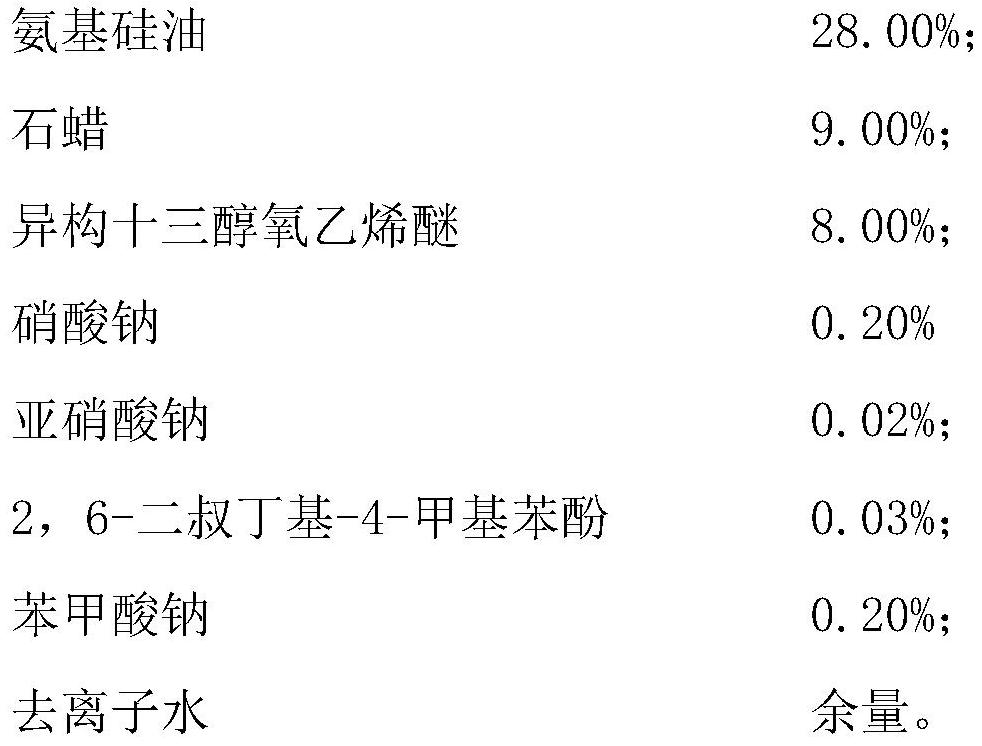

[0030] A kind of hydrophilic normal temperature rolling liquid is prepared from the following raw materials in mass percentage:

[0031]

[0032] In the preparation method of the present invention, each reaction substance is weighed according to the mass percentage, and then mixed uniformly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides hydrophilic normal-temperature rolling liquid which is prepared from amino silicon oil, paraffin, iso-tridecanol oxyethylene ether, sodium nitrate, sodium nitrite, 2, 6-di-tert-butyl-4-methylphenol, sodium benzoate and deionized water. The rolling liquid for producing the strip steel by the cold rolling unit provided by the invention is a hydrophilic formula, and through the novel hydrophilic formula, the technical problems of fire blast danger, pollution discharge pollution, degreasing power consumption, stirring and oil-water layering of traditional rolling oil can be thoroughly solved. During cold rolling of the strip steel, fire blast danger is avoided, oil and water are not layered, degreasing is avoided, stirring is avoided, less pollution is discharged, and safe and low-consumption clean production is achieved.

Description

Technical field: [0001] The invention belongs to the field of chemical industry and relates to a rolling fluid, in particular to a hydrophilic normal temperature rolling fluid. Background technique: [0002] In recent years, the rolling technology of cold-rolled thin plate has undergone great progress, and the cold-rolled tandem rolling mill has developed in the direction of high speed, full continuous, high precision, large deformation and thin gauge, especially the quality and quality of stainless steel plate to strip steel surface Cleanliness also puts forward higher and higher requirements. At the same time, the danger of explosion during the production of traditional rolling oil, the hazardous waste treatment of rolling oil waste, and the environmental protection pressure of the emulsion discharge have become the traditional rolling oil. development bottleneck. [0003] Traditional rolling oil has the following characteristics when it is put into production: [0004] ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M173/00C10N40/24C10N30/06C10N30/10C10N30/12

CPCC10M173/00C10M2229/052C10M2205/16C10M2209/104C10M2209/108C10M2201/083C10M2201/082C10M2207/026C10M2207/141

Inventor 郭圣倾

Owner 郭圣倾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com