Joint injection preparation based on collagen-binding polypeptide modified hyaluronic acid and its preparation method and application

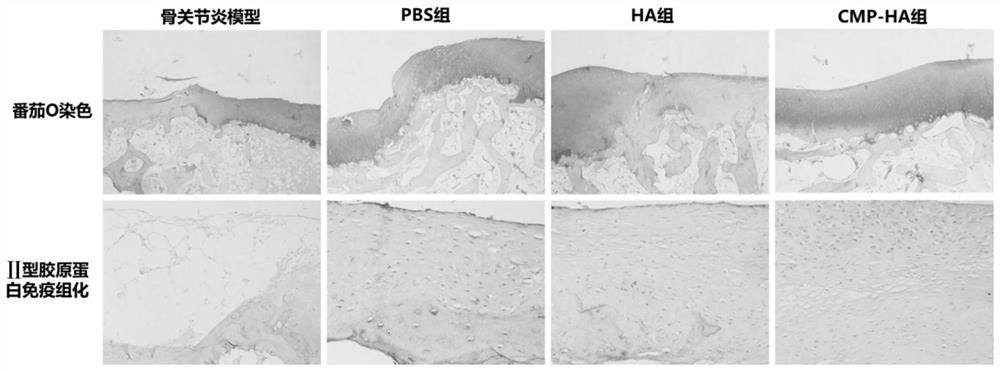

A hyaluronic acid and peptide-binding technology, which is applied in pharmaceutical formulations, prostheses, drug delivery, etc., can solve problems such as joint injection preparations not combining with damaged cartilage surfaces, multiple injections and repeated administration, etc., to achieve good resistance Non-specific adsorption performance, overcoming insufficient lubrication performance, good biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

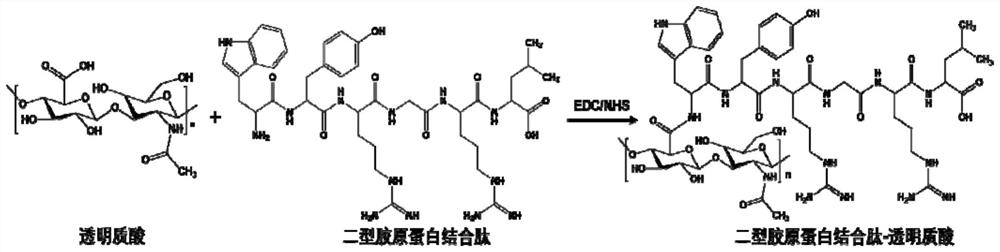

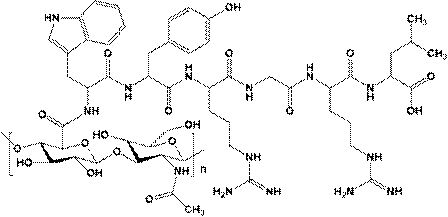

[0034] 1) Preparation of collagen-binding polypeptide-modified hyaluronic acid:

[0035] Prepare a 10 mmol / L phosphate buffer solution with pH=7.4 with disodium hydrogen phosphate dodecahydrate and potassium dihydrogen phosphate. Dissolve 1.2g of hyaluronic acid (HA) in 120mL of the above phosphate buffer, adjust the pH of the solution to 5 with 1.0mol / L hydrochloric acid, and then add 1-ethyl-(3-dimethylamino Propyl) carbodiimide hydrochloride (1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and hyaluronic acid repeating unit molar ratio is 1:1), after stirring for 20min Collagen-binding polypeptides were added (the molar ratio of collagen-binding polypeptides to hyaluronic acid repeating units was 1:1), the pH of the solution was maintained at 5 with 1 mol / L hydrochloric acid, and the reaction was stirred at 20° C. for 1 hour. The reacted solution was placed in a dialysis bag (MWCO: 8000-14000Da), and dialyzed in an aqueous solution with pH=5.0 for 2 days, and th...

Embodiment 2

[0053] 1) Preparation of collagen-binding polypeptide-modified hyaluronic acid:

[0054] Prepare a 10 mmol / L phosphate buffer solution with pH=7.4 with disodium hydrogen phosphate dodecahydrate and potassium dihydrogen phosphate. Dissolve 1.2g of hyaluronic acid (HA) in 120mL of the above phosphate buffer, adjust the pH of the solution to 5.5 with 1.0mol / L hydrochloric acid, and then add 1-ethyl-(3-dimethylamino Propyl) carbodiimide hydrochloride (1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and hyaluronic acid repeating unit molar ratio is 1:1), after stirring for 25min Collagen-binding polypeptides were added (the molar ratio of collagen-binding polypeptides to hyaluronic acid repeating units was 2:1), the pH of the solution was maintained at 5.5 with 1 mol / L hydrochloric acid, and the reaction was stirred at 25°C for 2 hours. The reacted solution was placed in a dialysis bag (MWCO: 8000-14000Da), and dialyzed in an aqueous solution with pH=5.0 for 2 days, and...

Embodiment 3

[0070] 1) Preparation of collagen-binding polypeptide-modified hyaluronic acid:

[0071] Prepare a 10 mmol / L phosphate buffer solution with pH=7.4 with disodium hydrogen phosphate dodecahydrate and potassium dihydrogen phosphate. Dissolve 1.2g of hyaluronic acid (HA) in 120mL of the above phosphate buffer, adjust the pH of the solution to 6 with 1.0mol / L hydrochloric acid, and then add 1-ethyl-(3-dimethylamino Propyl) carbodiimide hydrochloride (1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and hyaluronic acid repeating unit molar ratio is 1:1), after stirring for 30min Collagen-binding polypeptides were added (the molar ratio of collagen-binding polypeptides to hyaluronic acid repeating units was 3:1), the pH of the solution was maintained at 6 with 1 mol / L hydrochloric acid, and the reaction was stirred at 30°C for 3 hours. The reacted solution was placed in a dialysis bag (MWCO: 8000-14000Da), and dialyzed in an aqueous solution with pH=5.0 for 2 days, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com