Foam brick conveying device for building

A technology for transporting devices and foam bricks, which is applied in the direction of transport and packaging, transport of filamentous materials, conveyors, etc. It can solve the problems of low transport efficiency, time-consuming and laborious, and achieve the effect of improving transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

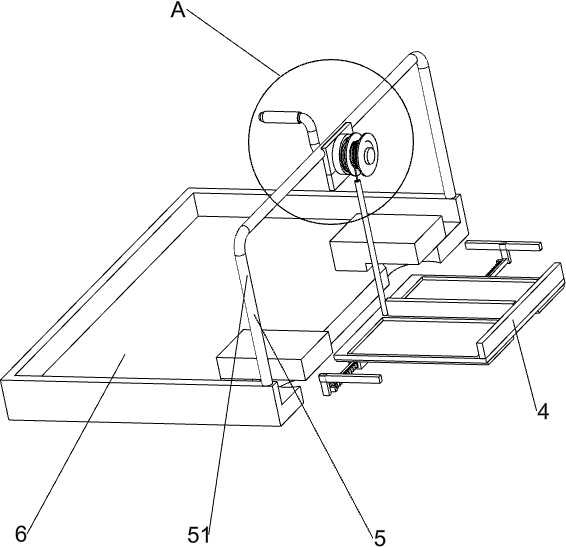

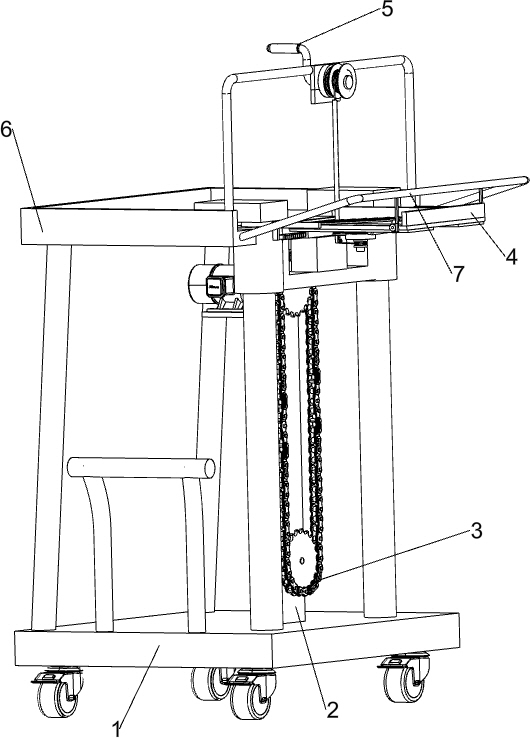

[0026] A kind of building foam brick conveying device, such as Figure 1-6 As shown, it includes a transport vehicle 1, a mounting plate 2, a transport mechanism 3, a transport plate 4, a brick shifting mechanism 5 and a support platform 6. The top of the transport vehicle 1 is vertically connected with a mounting plate 2, and a transporting plate 2 is installed on the mounting plate 2. Mechanism 3, the transport mechanism 3 is connected with a transport plate 4, the transport plate 4 is equipped with a brick moving mechanism 5, and the top of the transport vehicle 1 on the rear side of the installation plate 2 is connected with a support platform 6.

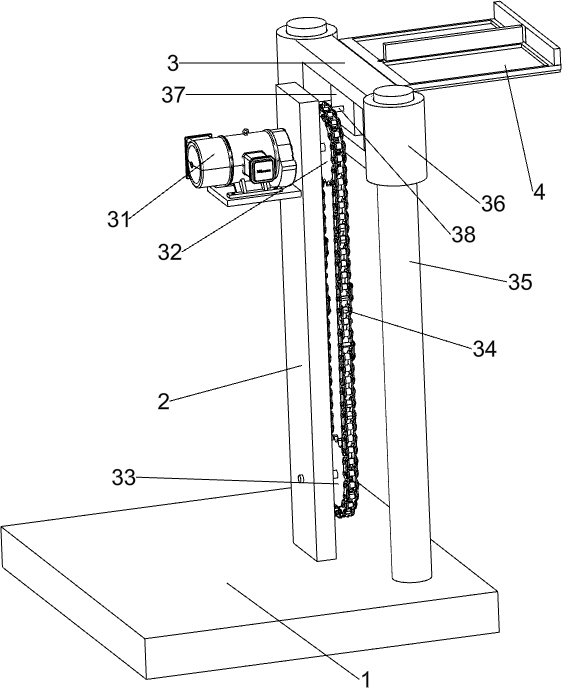

[0027] Transport mechanism 3 comprises decelerating motor 31, first sprocket wheel 32, second sprocket wheel 33, chain 34, guide rod 35, guide sleeve 36, movable block 37 and connecting rod 38, and decelerating motor 31 is installed on the back of mounting plate 2 On the upper part of the side, the output shaft of the reduction ...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 and Figure 7 As shown, also includes lower brick mechanism 7, lower brick mechanism 7 includes fixed rod 71, second rack 72, second gear 73, cam 74, turnover plate 75 and contact plate 76, the front side upper part of support platform 6 It is connected with a fixed rod 71, and the bottom front side of the fixed rod 71 is connected with two second racks 72, and the two second racks 72 are left and right symmetrical, and the front sides of the left side and the right side of the delivery plate 4 are connected in a rotational manner. There is a second gear 73, the second gear 73 meshes with the second rack 72, the second gear 73 is connected with a cam 74, and the top rear side of the transport plate 4 is hingedly connected with two flaps 75, and the two flaps 75 are left and right. Symmetrically, the top front side of the turnover plate 75 is connected with a contact plate 76 , and the bottom of the contact plate 76 is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com