Combined construction structure of underground road and ground bridge

An underground road and ground technology, applied in bridge construction, roads, bridges, etc., can solve the problems of time-consuming and laborious installation, road pulling, heavy weight, etc., and achieve the effects of convenient operation, smooth road surface and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

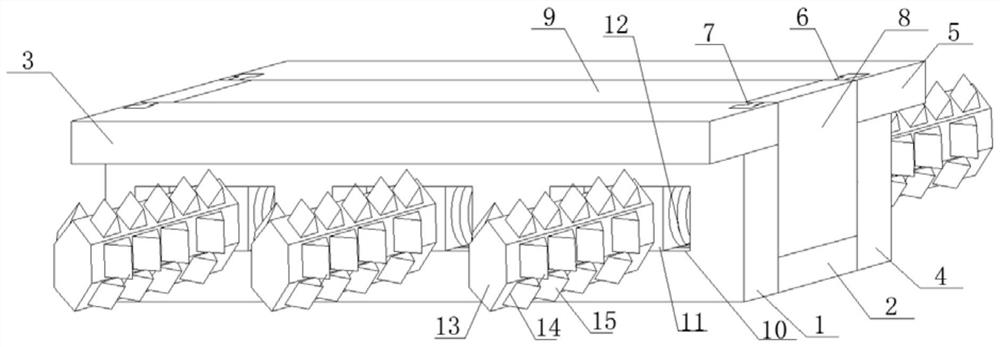

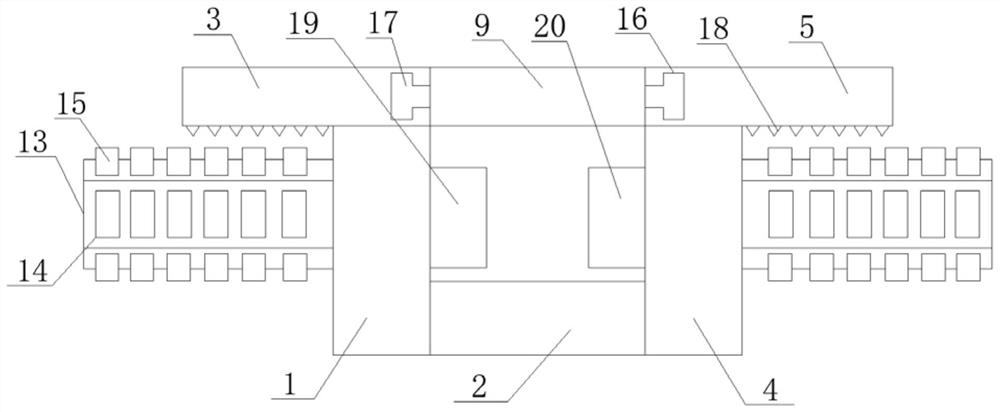

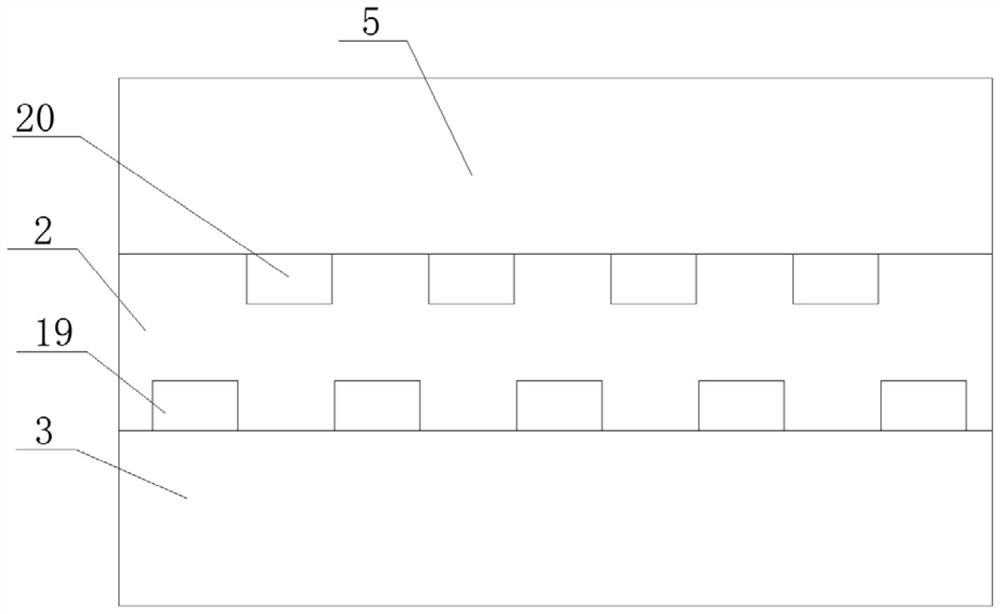

[0027] see Figure 1-3 , in an embodiment of the present invention, a joint construction structure of an underground road and a bridge on the ground, comprising a side riser-1, one side of the side riser-1 is horizontally welded with a fixed base plate 2, and one side of the side riser-1 The side is horizontally welded with a cover connecting plate 3, and the fixed bottom plate 2 is horizontally welded on one side of the side vertical plate 1 near the bottom surface, and the bottom surface of the fixed bottom plate 2 and the bottom surface of the side vertical plate 1 are kept at the same level, and the cover is connected Plate one 3 is horizontally welded on the side of side vertical plate one 1 away from the fixed bottom plate 2 and close to the top surface, and the top surface of cover plate one 3 is kept at the same level as the top surface of side vertical plate one 1, and the fixed bottom plate 2 Side vertical plate two 4 is horizontally welded with side vertical plate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com