Combined supporting structure for transverse shock resistance of three-span bridge

A technology of support structure and support mechanism, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as poor lateral seismic performance, and achieve reasonable and reliable structural design, improved protection effect, and stable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

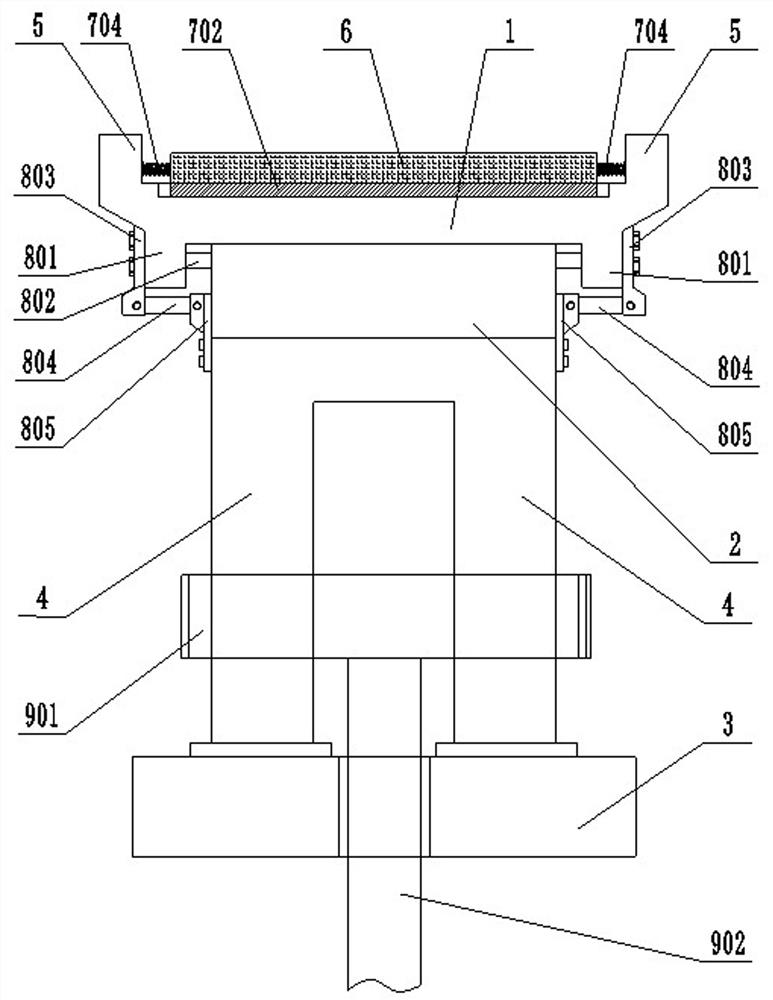

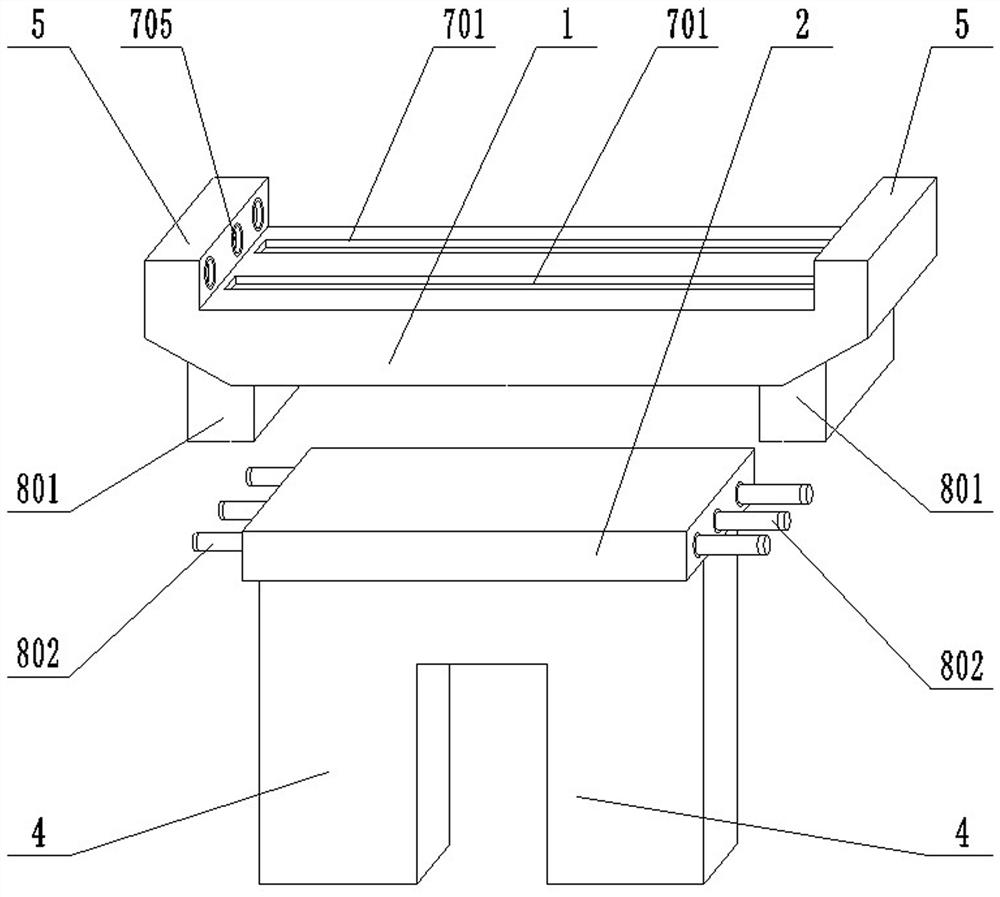

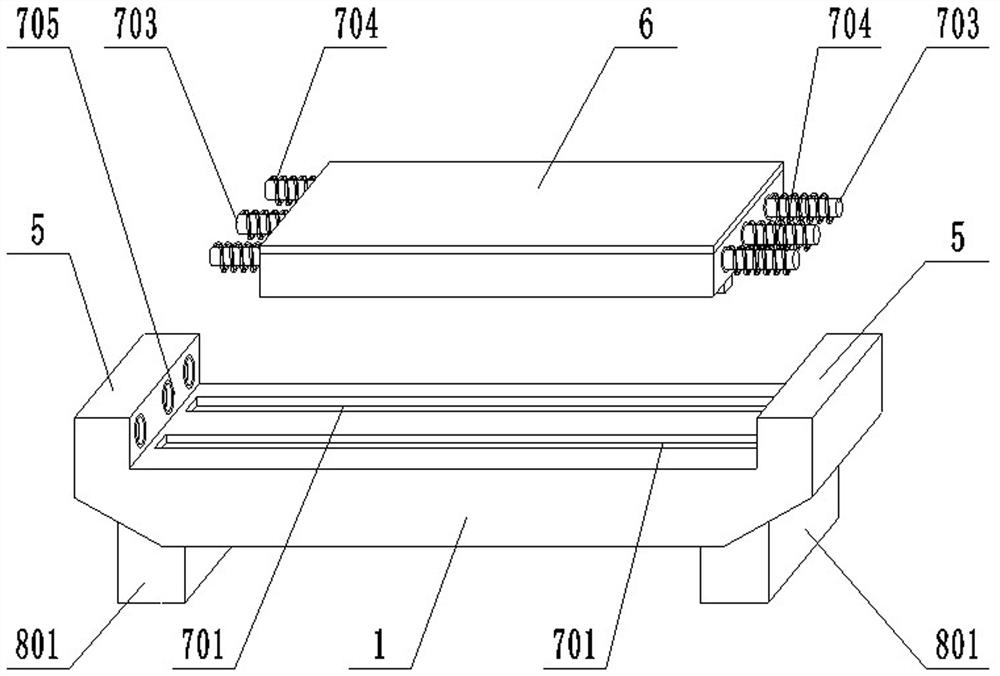

[0024] A combined support structure for lateral seismic resistance of a three-span bridge, comprising a bridge pier, a cover beam 1 and a pier cap 2 arranged between them; the bridge pier includes a foundation 3 and two vertically arranged on the foundation 3 and distributed left and right The pier columns 4, the tops of the two pier columns 4 are fixed as a whole; the upper surface edge of the cover beam 1 is integrally provided with two limit stoppers 5 placed longitudinally and parallel to the left and right; two limit stoppers 5 is horizontally provided with a bearing platform 6; a first support mechanism is provided between the cover beam 1 and the bearing platform 6; a second support mechanism is provided between the cover beam 1 and the pier cap 2;

[0025] The first supporting mechanism includes several sliding grooves 701 opened on the upper surface of the cover beam 1 and distributed parallel to the front and back; the lower surface of the carrying platform 6 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com