Display panel, manufacturing method thereof, and display device

A technology for display panels and substrates, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of the lifespan of the quantum dot color conversion layer and the effect of color conversion efficiency, and achieve the effect of improving reliability, quality and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

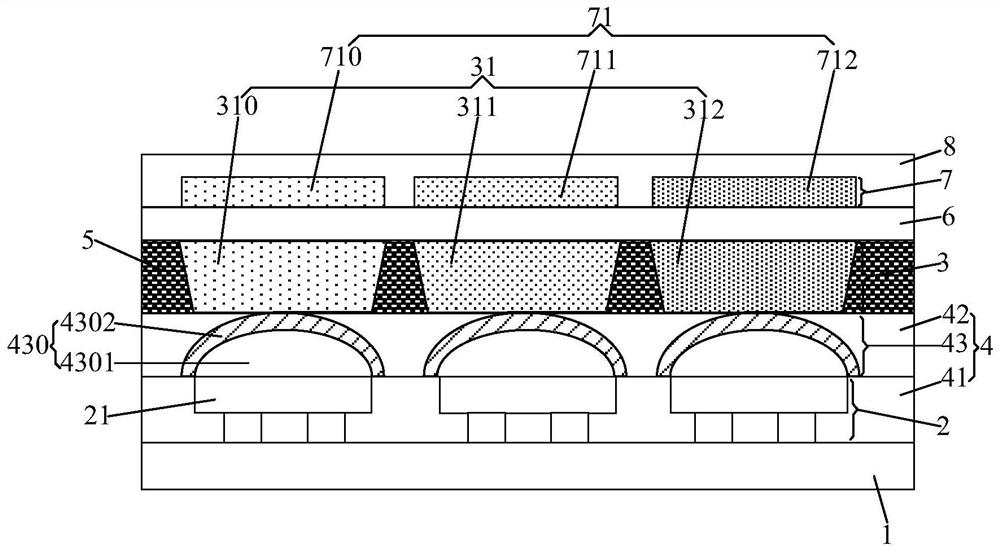

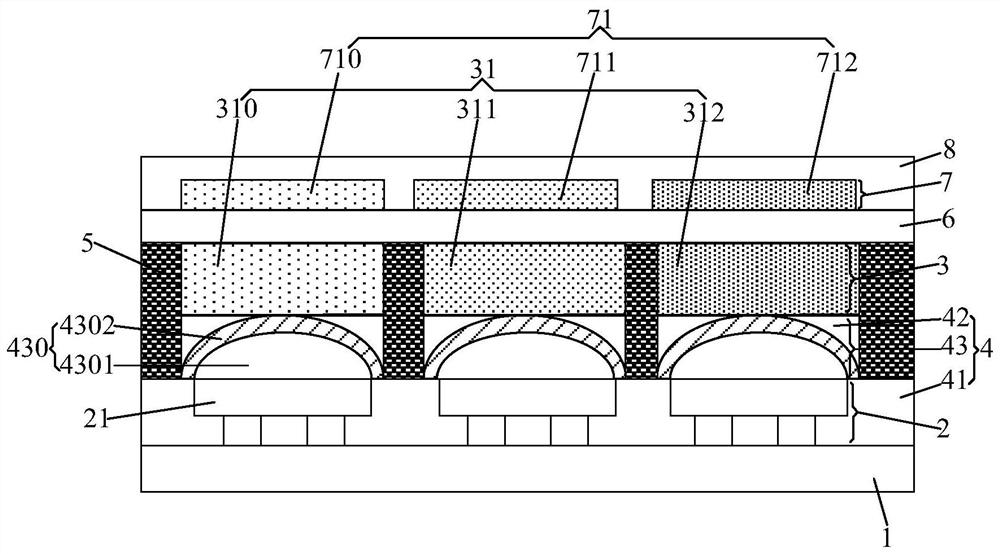

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, a display panel, a manufacturing method thereof, and a display device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] In a current public technology, the quantum dot color conversion layer is directly coated on the cover plate by adopting a “pair box” structure, the quantum dot color conversion layer is arranged in an array, and the quantum dot color conversion layer and the quantum dot color conversion layer are arranged in an array. Each MicroLED sub-pixel corresponds to one-to-one, and the cover plate is covered on the substrate where the MicroLED sub-pixel is located to form a closed structure. The box-shaped closed structure is airtight, and the actual working temperature of Micro LED is 80-120°C. High temperature has a great influence on the lifespan and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com