Manufacturing method of PCB

A production method and prepreg technology, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problems of complex manufacturing process, uneven groove bottom, and low depth control accuracy, and achieve simple manufacturing process and accurate depth Controllable, smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

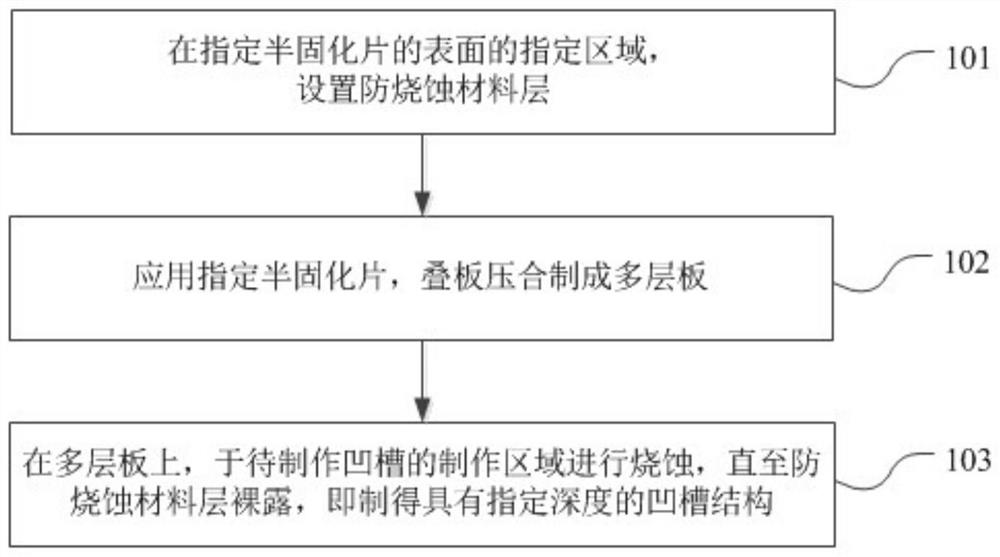

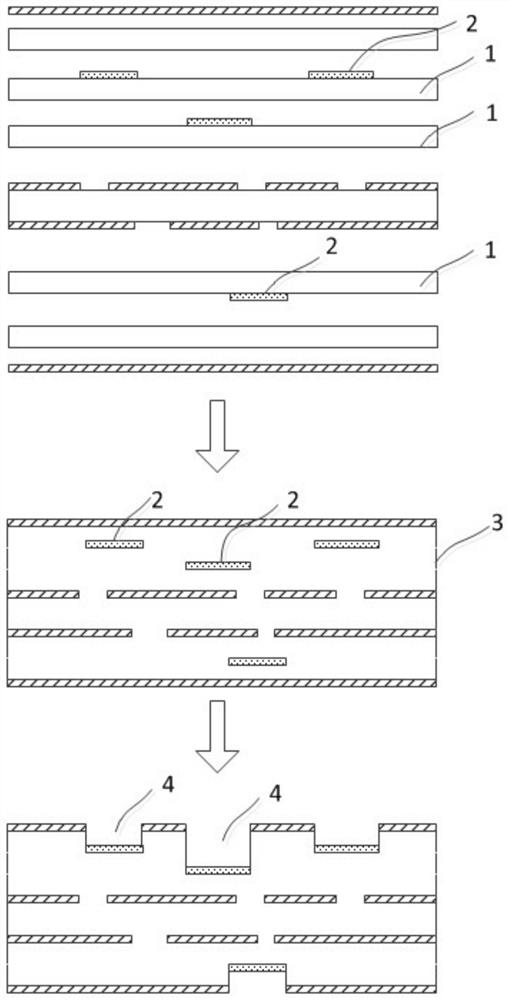

[0040] see figure 1 and figure 2 , the manufacturing method of the PCB that the embodiment of the present invention provides, comprises steps:

[0041] Step 101, setting an anti-ablation material layer 2 on a designated area on the surface of the designated prepreg 1 .

[0042] Wherein, the designated prepreg 1 refers to the prepreg located at the bottom of the groove of the PCB to be made. The specified area refers to the projection area of the groove to be made on the surface of the specified semi-solid sheet. According to the preset manufacturing requirements, the groove to be made has a specified depth; at the same time, the shape and size of the cross section of the groove to be made are not specifically limited.

[0043] The anti-ablation material layer 2 is made of materials that cannot or are difficult to be ablated by laser. Specifically, a material with ablation energy greater than that required by the prepreg can be selected, and it is soluble and can pass thr...

Embodiment 2

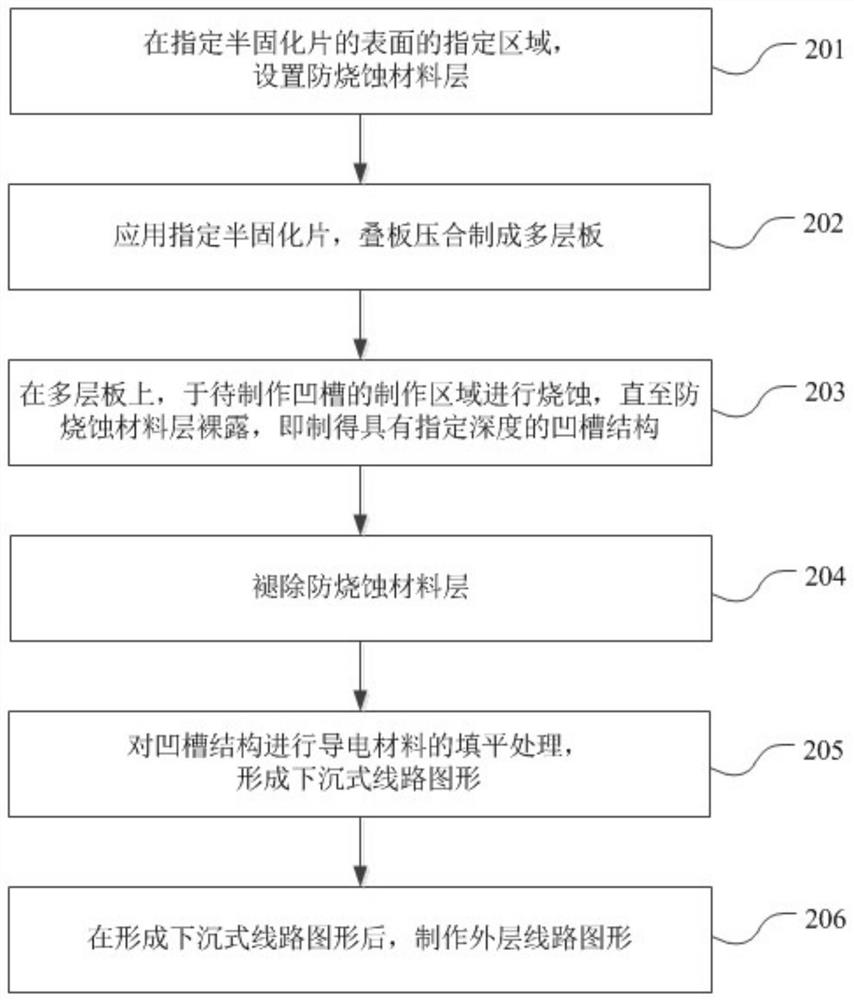

[0053] see image 3 and Figure 4 , the embodiment of the present invention provides another PCB manufacturing method, including steps:

[0054] Step 201, setting an anti-ablation material layer 2 on a designated area on the surface of the designated prepreg 1 .

[0055] In this embodiment, the anti-ablation material layer 2 is specifically an ink layer, which is coated on the surface of the specified prepreg 1 with a certain thickness.

[0056] Step 202 , apply the specified prepreg 1 , and press the laminated boards to form a multi-layer board 3 .

[0057] Step 203 , on the multi-layer board 3 , perform ablation in the region where the groove is to be made until the anti-ablation material layer 2 is exposed, that is, a groove structure 4 with a specified depth is made.

[0058] Step 204 , removing the anti-ablation material layer 2 .

[0059] Since the anti-ablation material layer 2 of this embodiment is ink, it can be removed by developing and etching with liquid medicine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com