Wire arrangement device for reinforcing steel bars

A technology of wire arrangement and steel bar, applied in the field of steel wire arrangement, can solve the problem of low service life of guide rollers, and achieve the effect of reducing loss and speed difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

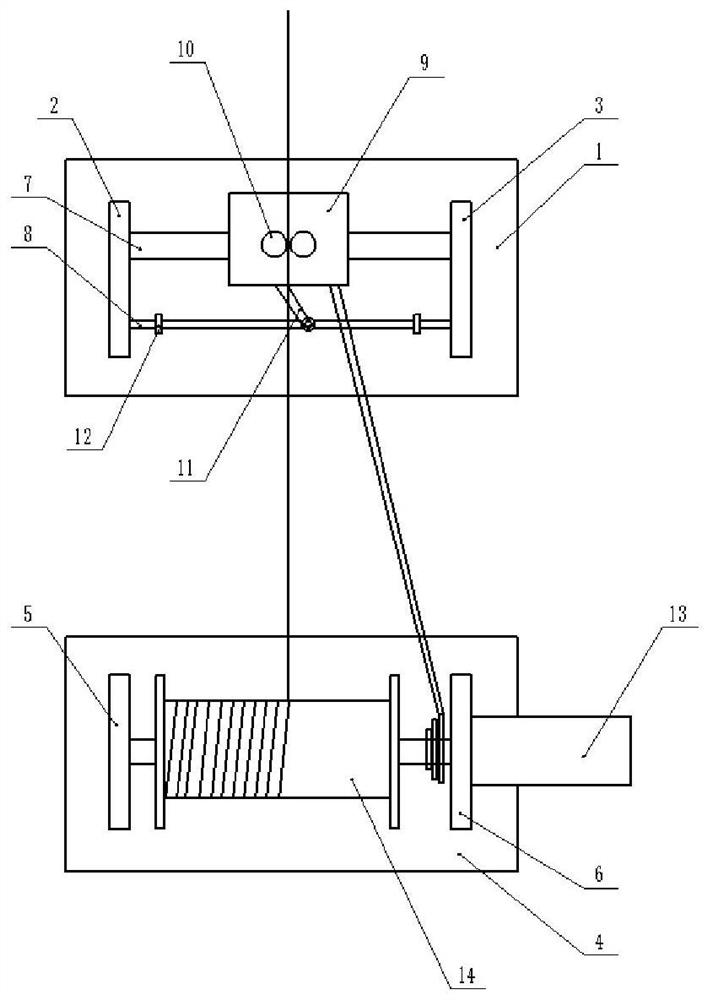

[0037] Such as figure 1 Shown, a kind of steel bar cable arrangement device comprises first frame, second frame, cable arrangement mechanism and I-shaped wheel 14 take-up mechanisms, leaves gap between the first frame and the second frame (this embodiment In the example, the distance between the two is 0.5m); wherein: the first frame includes the first base 1, the first left side plate 2 and the first right side plate 3, the first left side plate 2 and the first right side plate 3 are respectively welded on the left and right sides of the first base 1; the second frame includes the second base 4, the second left side plate 5 and the second right side plate 6, similarly, the second left side plate The side plates 6 are respectively welded and fixed on the left and right sides of the second base 4;

[0038] The cable arrangement mechanism includes a cable arrangement host 9, a guide shaft 7 and a stop guide rail 8. In this embodiment, the guide shaft 7 is a metal rod with a smo...

Embodiment 2

[0043] Compared with Embodiment 1, the only difference is that it also includes a limit rod. The top of the main body of the cable arrangement is welded with a left mounting block and a right mounting block. It is welded and fixed; it also includes a round tube, the limit rod runs through the round tube, and the round tube is connected to the limit rod in rotation; in other embodiments, in order to facilitate the adjustment of the upper and lower positions of the limit rod, the left and right mounting blocks are drilled There is a longitudinal slide rail, and a roller for moving in the slide rail is welded and fixed at both ends of the limit rod;

[0044] In addition, an infrared transmitter (model: SIR333) is bonded to the side of the left mounting block close to the limit rod. Similarly, an infrared receiver (model: LT0038) is fixedly bonded to the side of the right mounting block close to the limit rod. ); and the vertical height of the infrared receiver and the infrared em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com