Quick power taking socket with locking mechanism

A locking mechanism and electric socket technology, applied in the direction of circuits, electrical components, conductive connections, etc., can solve the problems of construction and installation time impact, loose socket needles, poor contact, etc., to improve stability and safety, structural design Reasonable and avoid the effect of needle deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

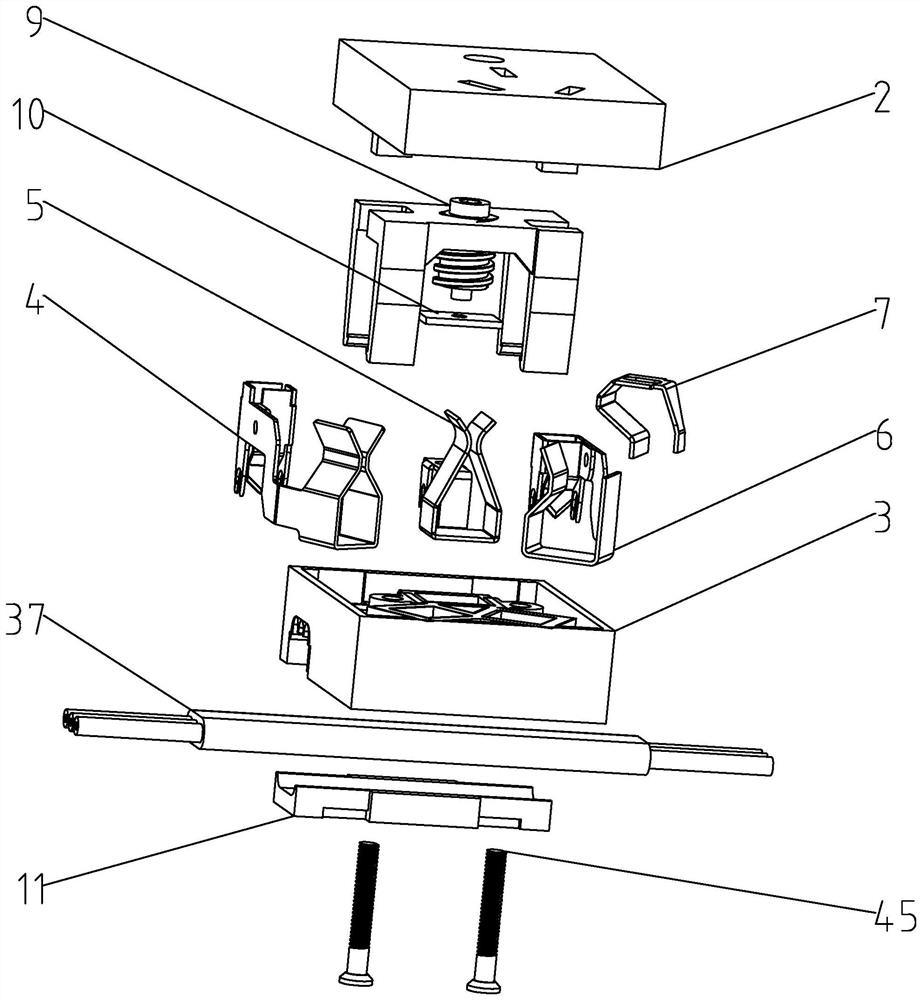

[0045] Such as figure 1 As shown, the present invention provides a technical solution, a quick power-taking socket with a locking mechanism, which is composed of a housing 1 , a power-taking and transmitting mechanism and a locking mechanism arranged in the housing 1 .

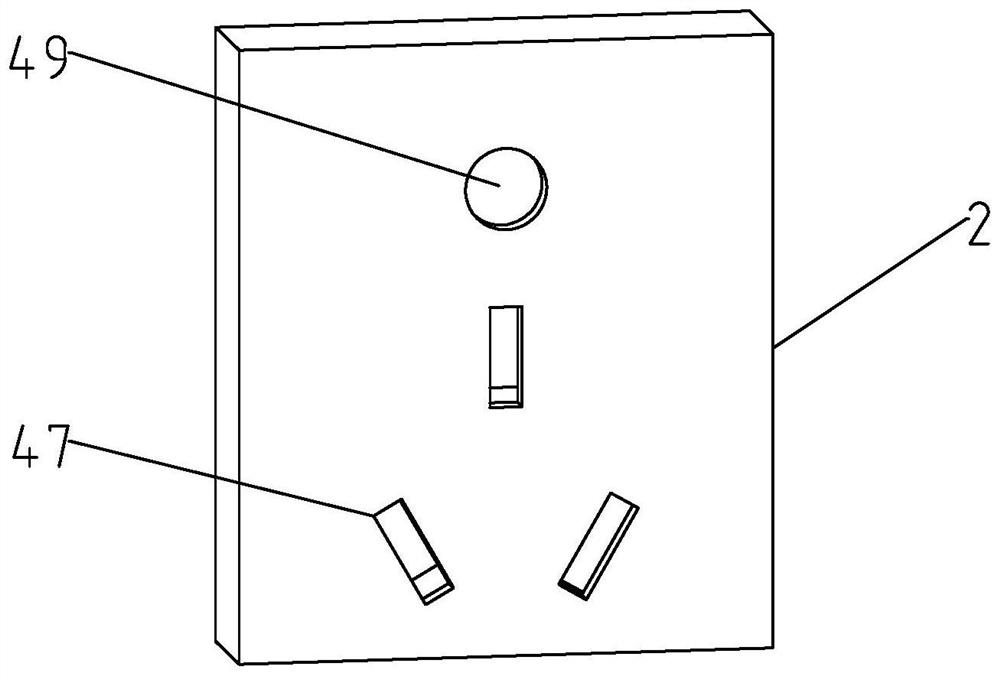

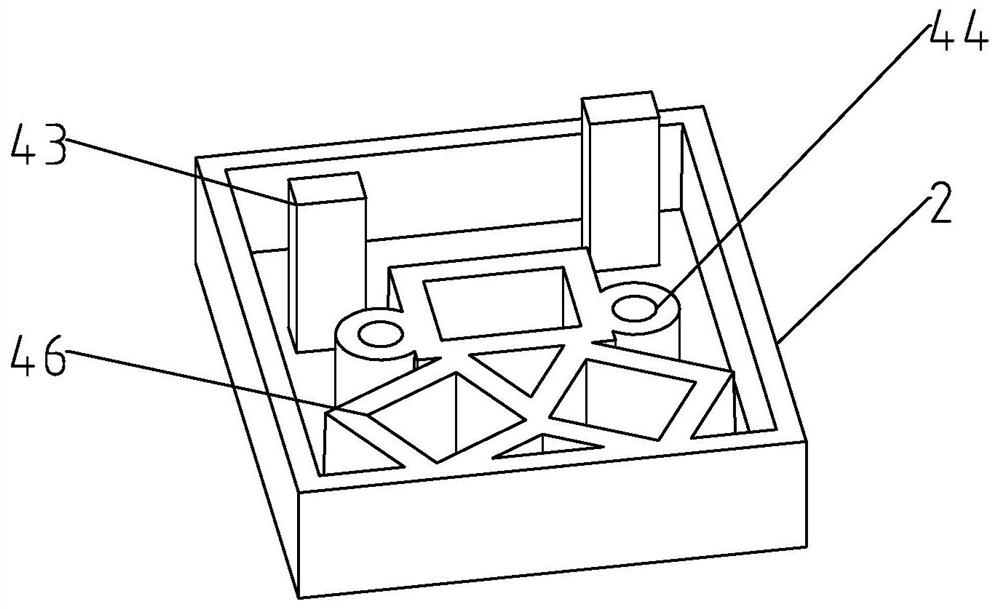

[0046] The housing 1 includes a socket upper cover 2 and a socket lower cover 3 that are interlocked together. The socket upper cover 2 and the socket lower cover 3 are cuboids of plastic material, and are fixed by fixing screws 45; The mechanism is composed of the zero line needle 4, the ground wire needle 5, the fire wire needle 6 and the contact piece 7 used in conjunction with the fire wire needle 6 installed in the socket lower cover 3; the locking mechanism is composed of a locking buckle 8, a locking screw 9. The positioning block 10 is composed of a locking and fixing cover 11. The locking and fixing cover 11 is clamped at the bottom of the locking buckle 8. The locking screw 9 is threaded in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com