Antibiotic microbe dreg treatment method

A technology of antibiotic bacteria residue and treatment method, applied in the field of environmental engineering, can solve problems such as low antibiotic efficiency, and achieve the effects of low environmental risk, strong operability, and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for treating antibiotic bacteria residues, specifically, 99 parts of antibiotic bacteria residues are fully pulverized, 1 part of meat and bone meal is pulverized, and then the two are fully mixed, and placed at 10°C-45°C for curing, and the meat and bone meal It can stimulate indigenous microorganisms to degrade antibiotics and carry out harmless treatment of bacterial residues.

[0023] The antibiotic residue used in this example comes from Shandong Lukang Medicine, and the initial penicillin concentration is 1650 μg / g. The meat and bone meal used in this example is obtained from Remsoil Company of Finland.

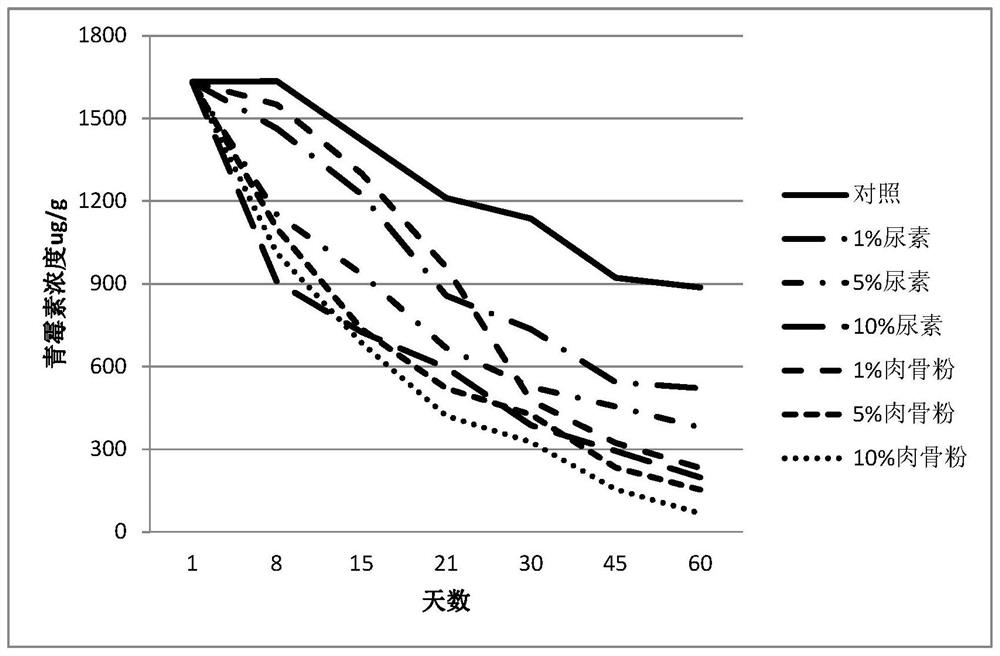

[0024] figure 1 It shows that within 60 days, the antibiotic concentration of the treatment group added with meat and bone meal compared with the control group without meat and bone meal has changed over time, and after 60 days, the antibiotic concentration in the antibiotic bacteria residue has decreased by 85.76%.

Embodiment 2

[0026] A method for treating antibiotic bacteria residues, specifically, 95 parts of antibiotic bacteria residues are fully pulverized, 5 parts of meat and bone meal are pulverized, and then the two are fully mixed, placed at 10°C-45°C for curing, and the meat and bone meal It can stimulate indigenous microorganisms to degrade antibiotics and carry out harmless treatment of bacteria residues. After a certain period of time, the concentration of antibiotics in antibiotic bacteria residues is reduced by 90.61%.

[0027] The antibiotic residue used in this example comes from Shandong Lukang Medicine, and the initial penicillin concentration is 1650 μg / g. The meat and bone meal used in this example is obtained from Remsoil Company of Finland.

Embodiment 3

[0029] A method for treating antibiotic bacteria residues, specifically, 90 parts of antibiotic bacteria residues are fully pulverized, 10 parts of meat and bone meal are pulverized, and then the two are fully mixed, and placed at 10°C-45°C for curing, and the meat and bone meal It can stimulate indigenous microorganisms to degrade antibiotics and carry out harmless treatment of bacteria residues. After a certain period of time, the concentration of antibiotics in antibiotic bacteria residues is reduced by 95.83%.

[0030] The antibiotic residue used in this example comes from Shandong Lukang Medicine, and the initial penicillin concentration is 1650 μg / g. The meat and bone meal used in this example is obtained from Remsoil Company of Finland.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap