Fixture device for changing laser processing angle

A fixture device and laser processing technology, applied in auxiliary devices, manufacturing tools, laser welding equipment, etc., to achieve the effect of simple device structure, convenient processing and research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

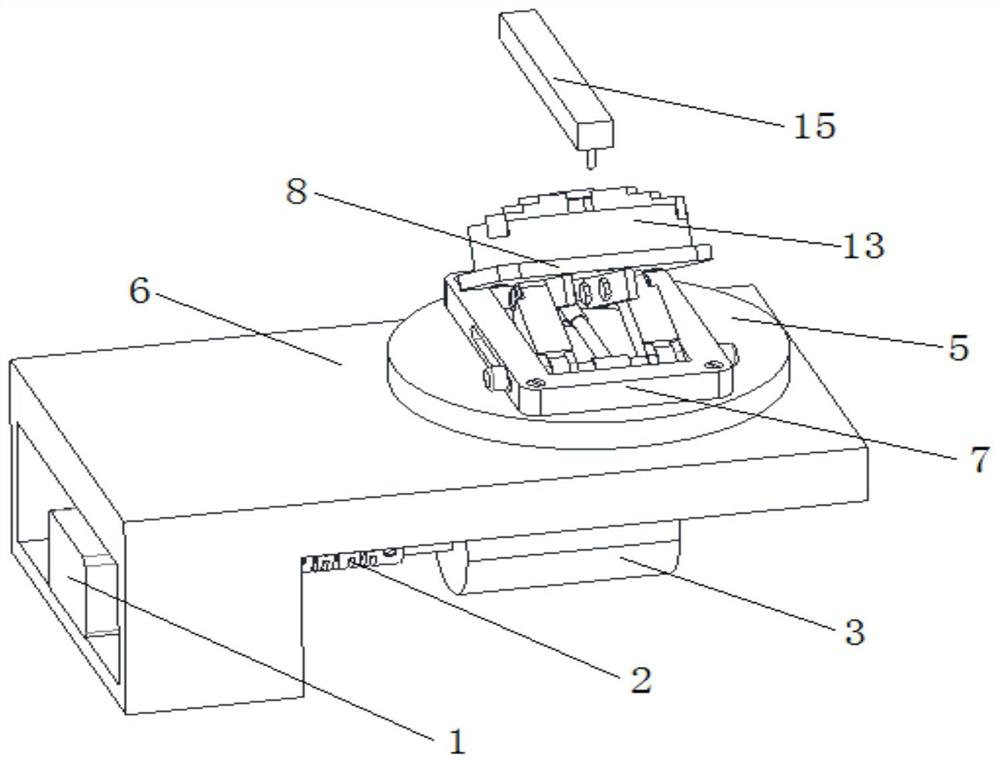

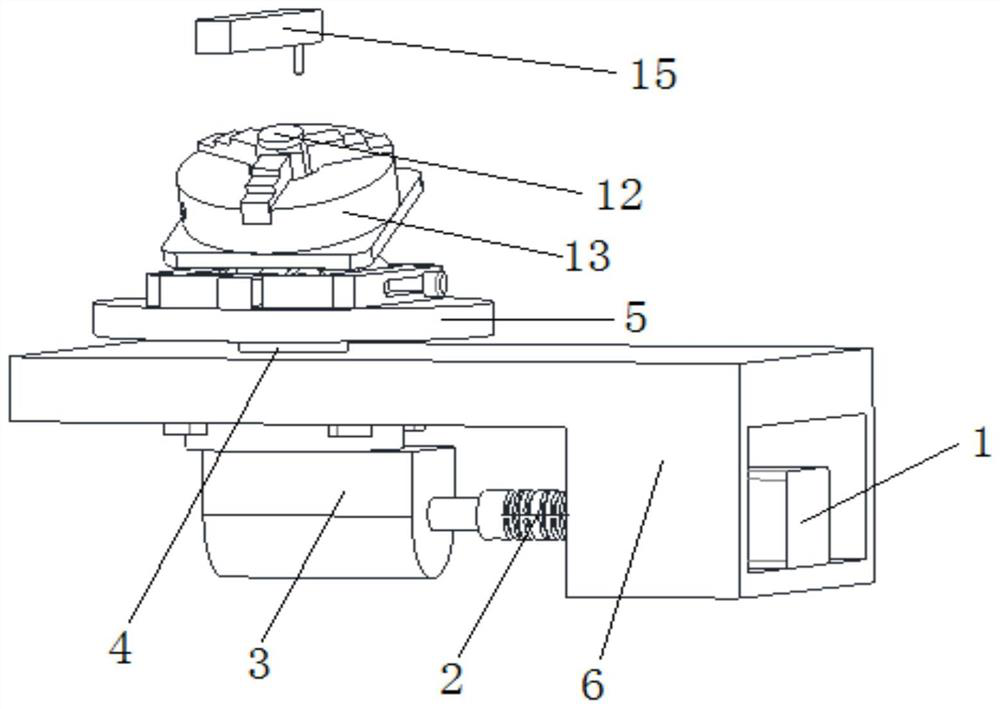

[0024] like figure 1 As shown, a fixture device for changing the angle of laser processing includes a tilting mechanism for carrying a workpiece 12 and driving the workpiece 12 to tilt, a rotating mechanism for driving the tilting mechanism to rotate, and a pallet 6 . A laser marking machine 15 for laser processing the workpiece 12 is arranged above the pallet 6 .

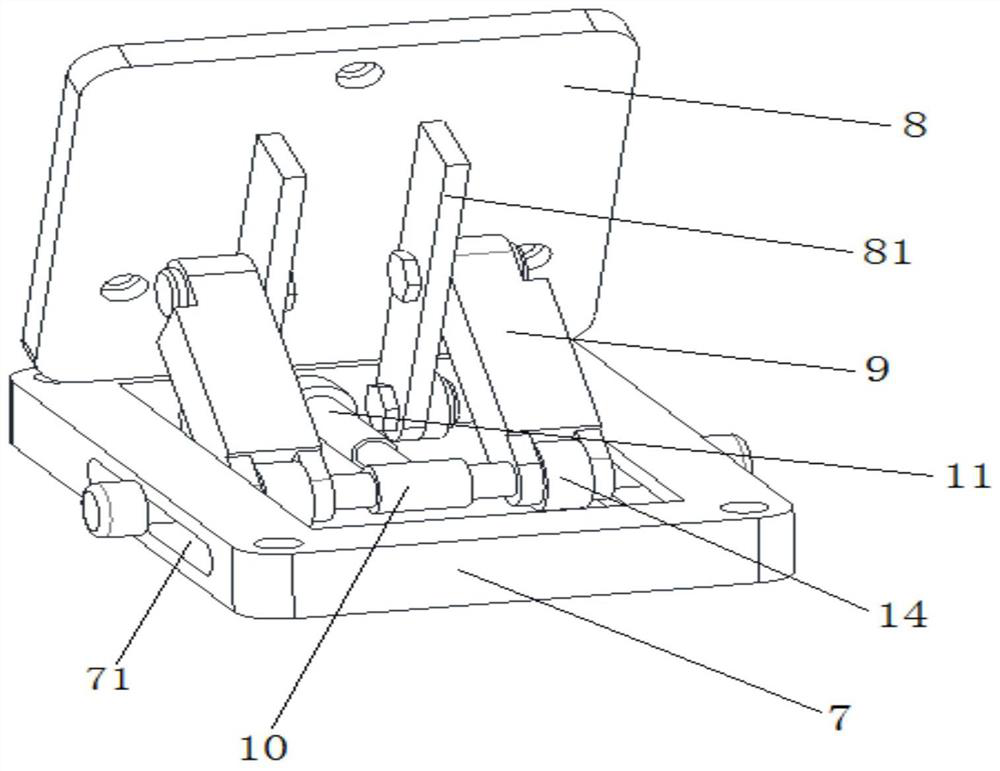

[0025] like figure 2 As shown, the tilting mechanism: comprises a bottom plate 7 of a return-shaped frame structure, a workbench 8, two transmission rods 9, a connecting shaft 10 and an electric push rod 11; the opposite sides of the bottom plate 7 of a return-shaped frame structure The wall is provided with a chute 71, the connecting shaft 10 is slidably connected in the chute 71, and the two ends of the connecting shaft 10 have limit structures (not shown in the figure), which are used to prevent the connecting shaft 10 from breaking away from the chute 71 during the sliding process , one side of the workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com