Label printer

A technology for printers and signs, applied in typewriters, printing devices, printing, etc., can solve the problems of inconvenient operation and inability to lock the track, and achieve the effect of overall compactness, high degree of automation, and strong reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

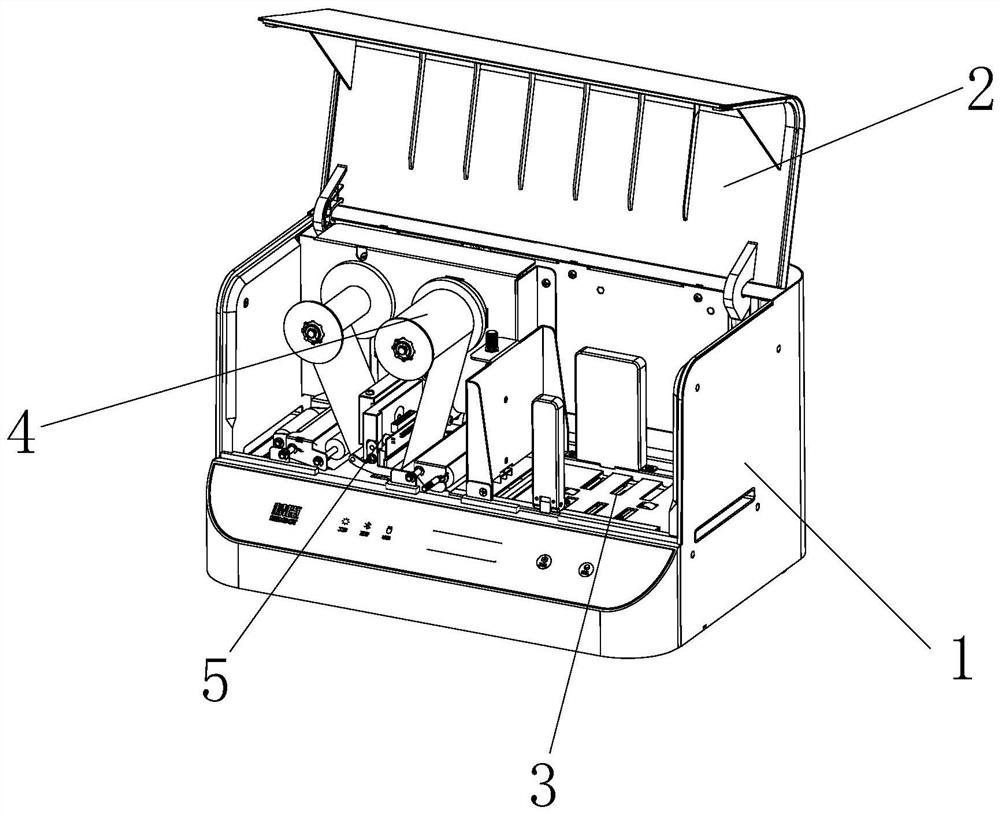

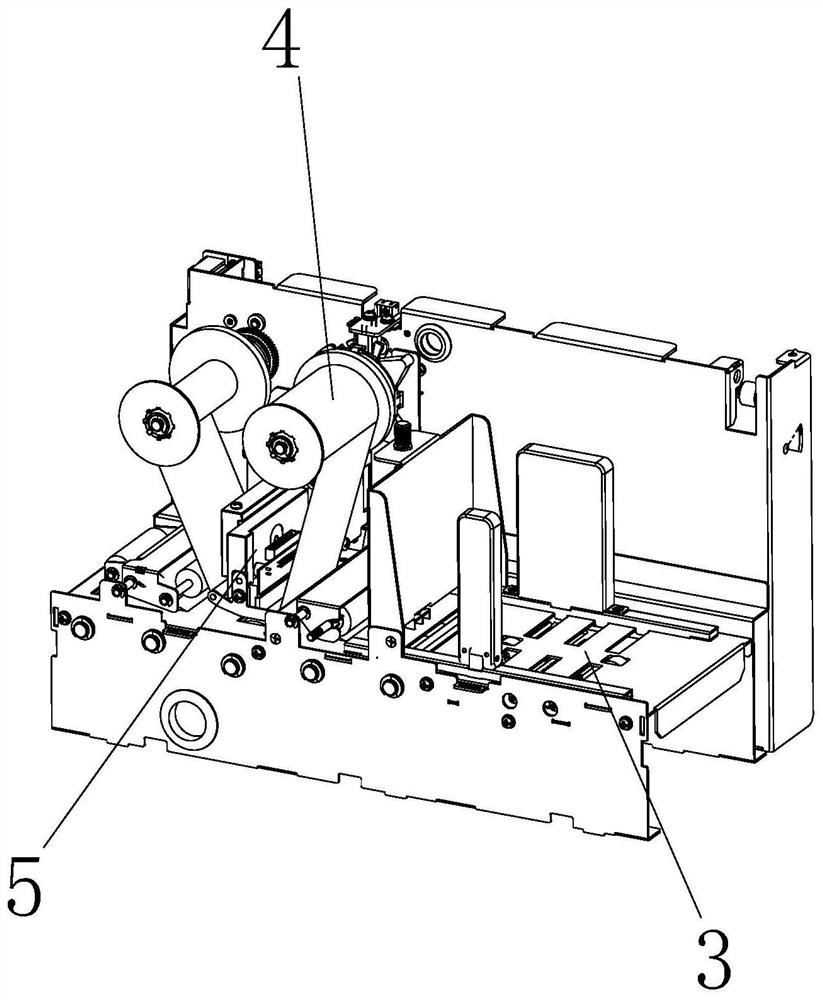

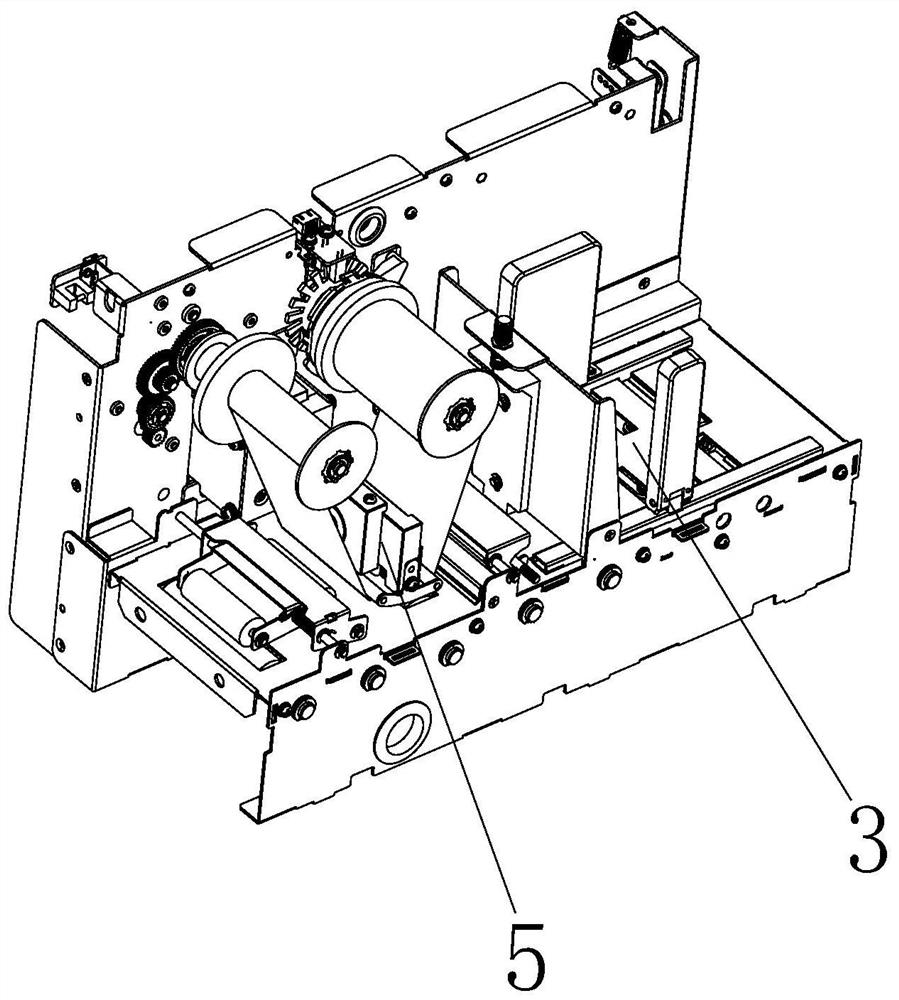

[0043] like Figure 1-17 As shown, the signage printer of the present invention includes a box body 1 and a cover body 2 . The box body 1 is provided with a track fixing device 3 , a ribbon roll 4 and a print head driving device 5 .

[0044] The printer track fixing device 3 includes a base, a left guide rail 3-4, a right guide rail 3-5, a movable baffle 3-6, a fixed baffle 3-7, a fixed plate 3-8, a gear 3-11, the first rack 3-9 and the second rack 3-10.

[0045] In this embodiment, the base is a frame structure, which includes a left panel 3-2, a right panel 3-3 and a top panel 3-1. Both sides of fixed plate 3-8 are provided with first inserting sheet 3-15, second inserting sheet 3-16, the 3rd inserting sheet 3-17 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap