Electronic industry recycled water treatment system and process

A treatment system and technology in the electronics industry, applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve unreasonable design, disclosure of water production rate, failure to effectively meet production needs, etc. To solve the problem, achieve the effect of reasonable structure and process design, and reduce the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

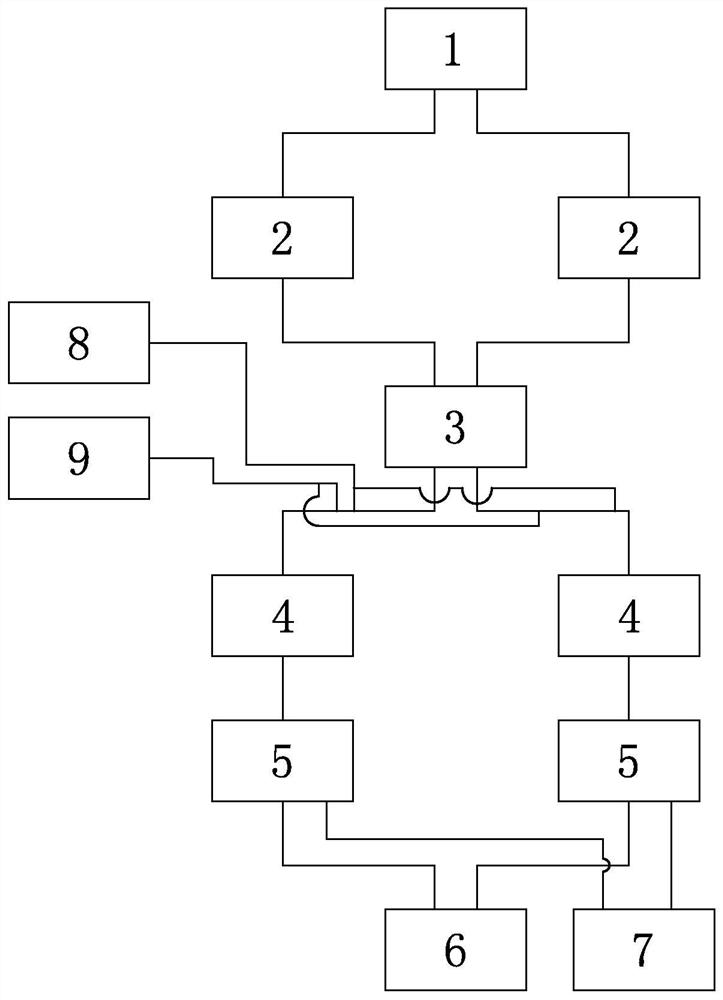

Image

Examples

Embodiment 1

[0032] In a project where the primary RO is in full operation, about 1,400 tons of concentrated water is discharged to wastewater every day. In order to respond to energy conservation and reduction, discharge and reduce tap water consumption, a new primary RO concentrated water recovery system is added, and the primary RO concentrated water can be recycled every day. 50% of the water is used for the pure water system to reduce the consumption of tap water.

[0033] 1 set of RO concentrated water collection tank: volume 30m 3 , diameter 3500mm, height 3600mm, material FRP;

[0034] 2 sets of positive resin towers: diameter 1200mm, height 2410mm, Rohm and Haas 1500L, material CS / RL;

[0035] 1 set of decarbonization tower: diameter 1200mm, height 5500mm, with multi-faceted hollow balls 1.6m inside 3 ;

[0036] 2 sets of security filters: pore size 5μm, processing speed 30m 3 / h, material SUS304;

[0037] 2 sets of concentrated water RO devices: the recovery rate is 50%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap