Gear detection bench

A gear detection and gear technology, applied in measuring devices, electromagnetic measuring devices, electromagnetic/magnetic thickness measurement, etc., can solve the problems of long time and complicated measurement process, and achieve the effect of high integration, high efficiency and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the implementation modes in the present application and the features in each implementation mode can be combined with each other.

[0025] Hereinafter, the present application will be described in detail with reference to the accompanying drawings and in combination with embodiments.

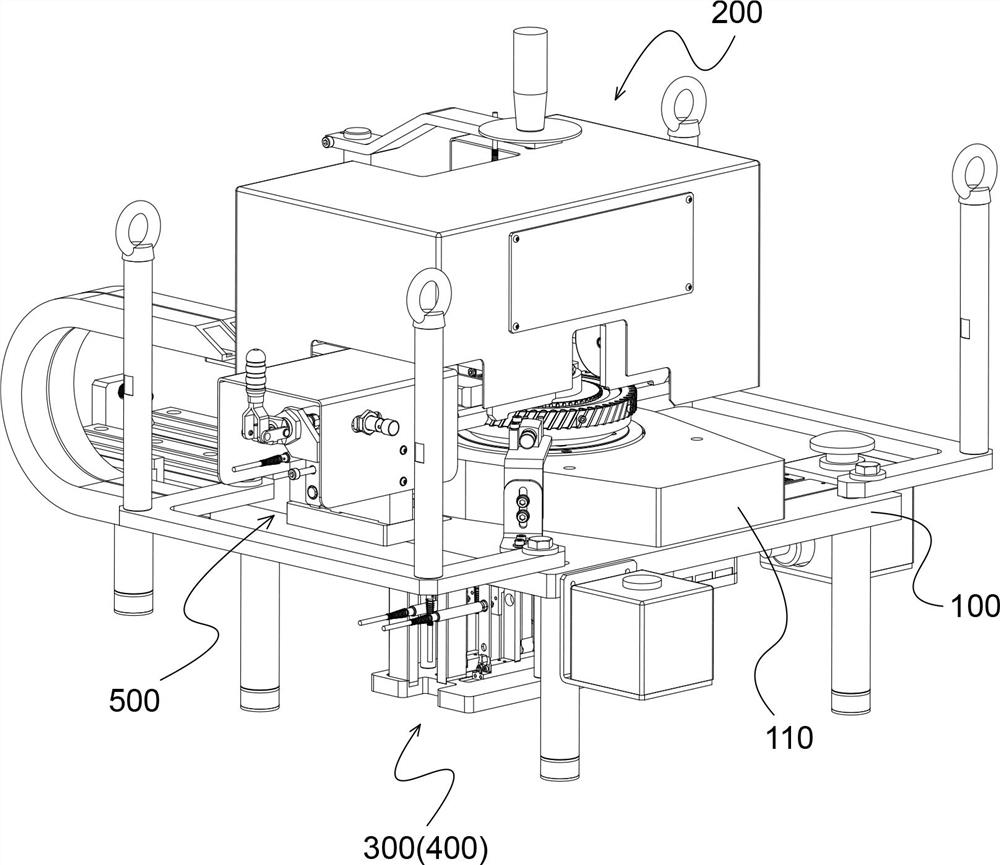

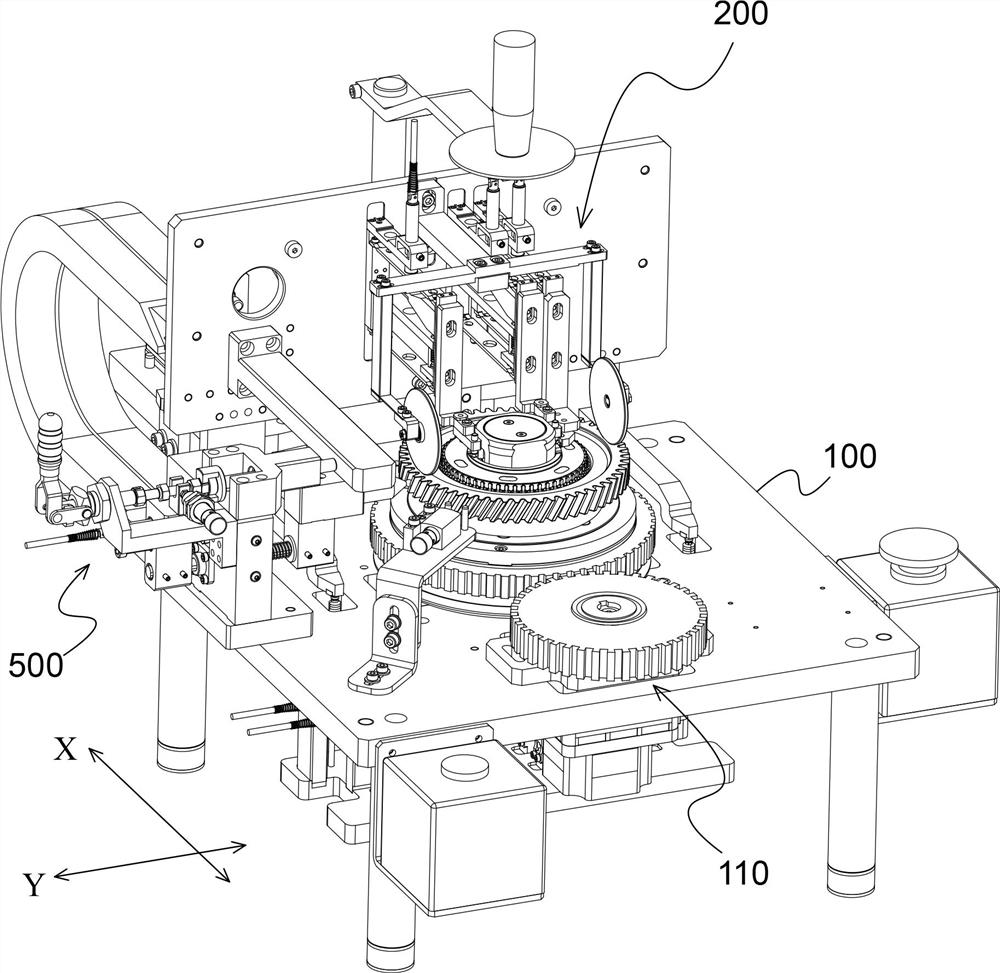

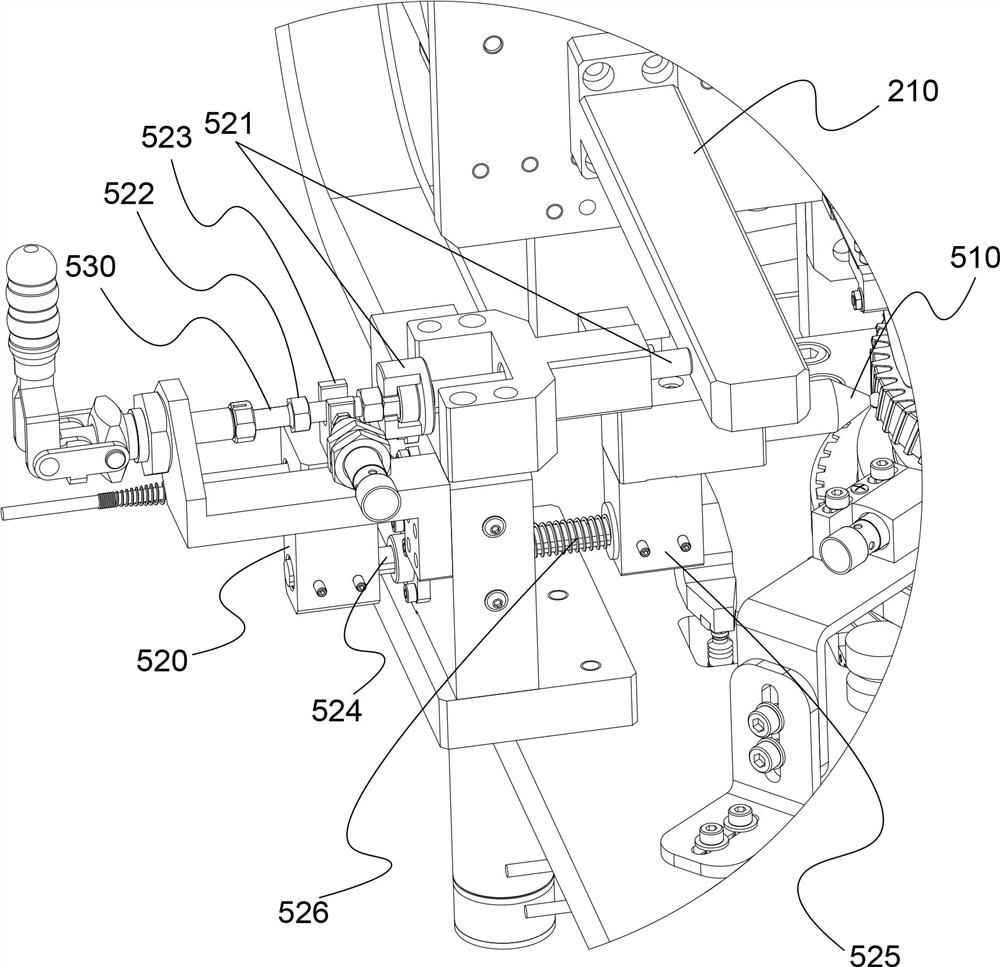

[0026] Such as figure 1 As shown, the present application provides a gear detection platform, which includes a workbench 100, a first detection mechanism 200 for detecting the height of the upper end surface of the gear to be tested, and a first detection mechanism 200 for detecting the height of the lower end surface of the gear to be tested. The second detection mechanism 300, the third detection mechanism 400 for detecting the inner diameter of the gear to be tested and the fourth detection mechanism 500 for detecting the outer diameter of the gear to be measured, the workbench 100 includes a Rotary drive mechanism 110 .

[0027] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com