Dangerous goods chemical warehouse capable of being automatically repaired

An automatic repair and dangerous goods technology, applied in the direction of electric transmission signal system, fire rescue, etc., can solve the problems of large fire loss, difficult to control fire, and different effective fire extinguishing methods, so as to reduce casualties and prevent fire from spreading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

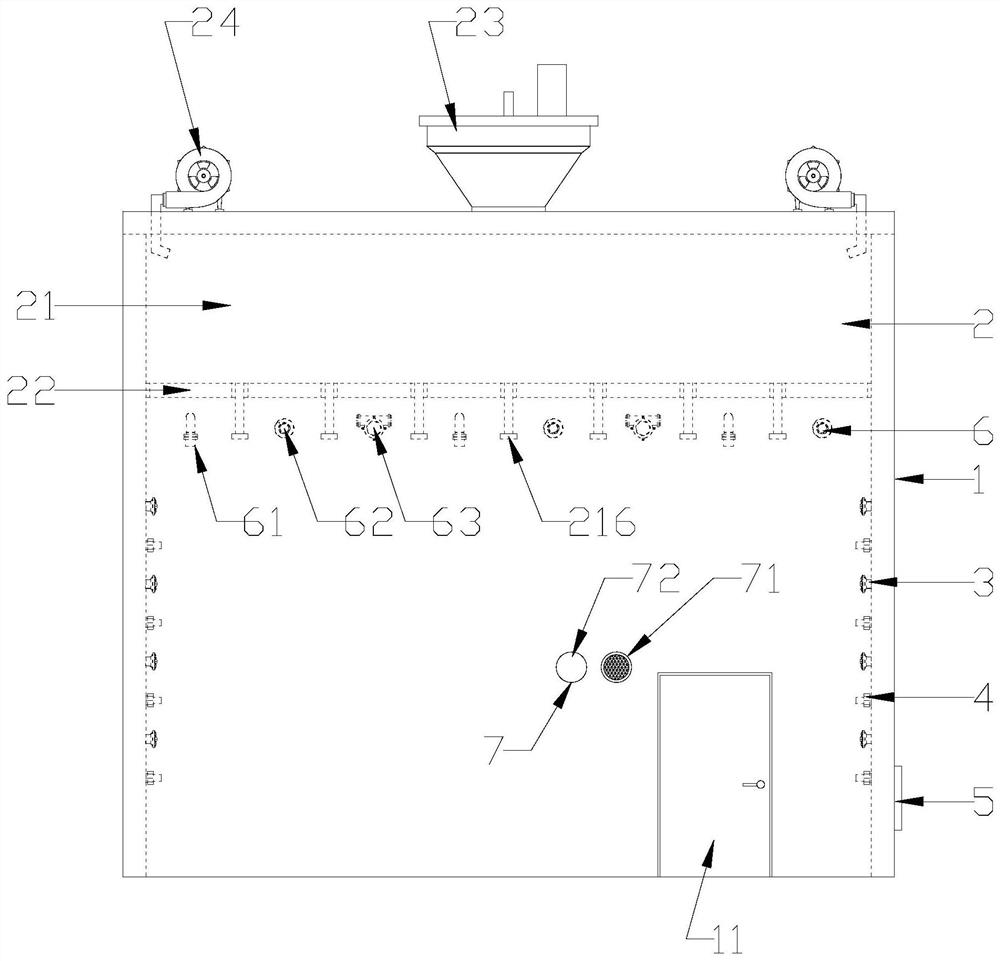

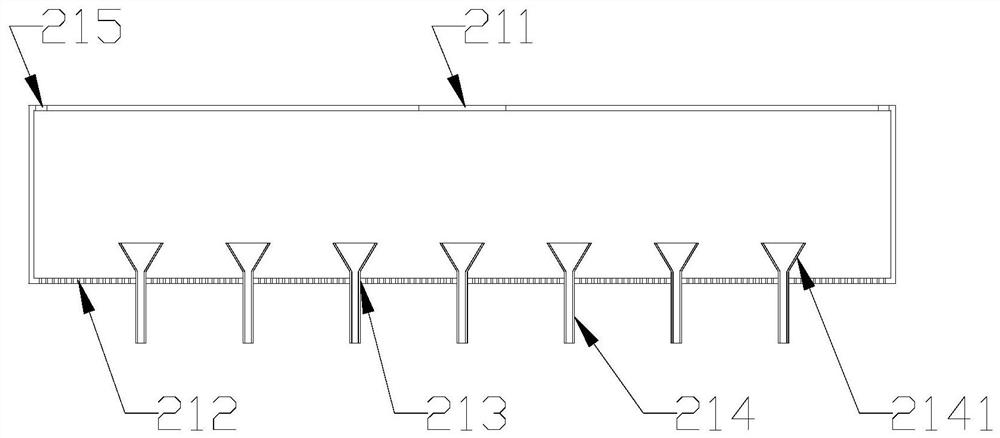

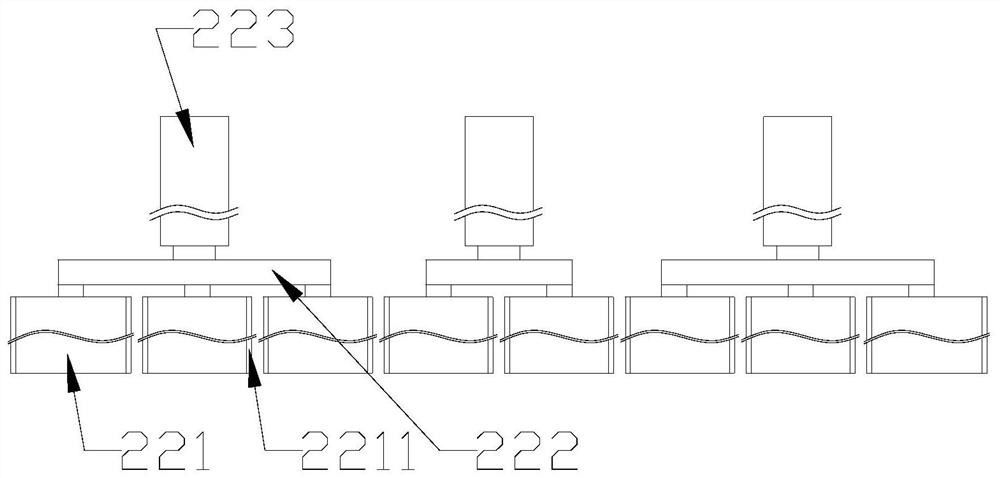

[0019] refer to figure 1 , figure 2 and image 3 , an automatically repairable dangerous goods chemical warehouse in the present invention includes a warehouse body 1, a fire-fighting sandbox 2, a controller 5 and a detector assembly 6, and the fire-fighting sandbox 2 includes a box body 21, a baffle assembly 22 and a Sand bucket 23, the box body 21 is fixed on the inner top of the warehouse body 1, and the center of the top surface of the box body 21 is provided with a sand inlet 211, and the sand inlet bucket 23 is fixed on the center of the outer top surface of the warehouse body 1 And the discharge pipe passes through the sand inlet 211 and extends into the inner cavity of the box body 21. The bottom surface of the box body 21 is provided with a sand leakage port 212 and several long sand leakage grooves 213 arranged at intervals. The sand guide flat pipe 214 is fixed on the sand length groove 213, and the baffle assembly 22 includes a plate body 221, a bracket 222 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com