A steel structure house and its installation method

A technology for steel structures and houses, applied in building construction, construction, building maintenance, etc., can solve problems such as affecting building safety, inability to achieve secondary adjustment, and prone to aging and deformation, reducing looseness or damage, accurate measurement. and adjustment, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, will not be described in detail here.

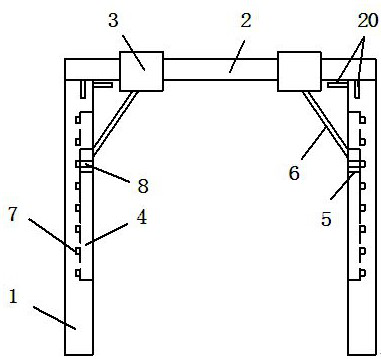

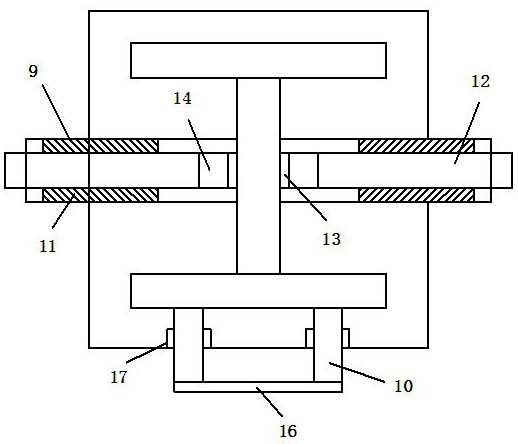

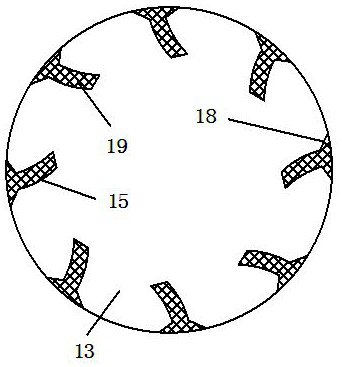

[0025] refer to Figure 1-3 , a specific embodiment of the present invention includes a side wall bracket 1 and several I-shaped steel beams 2 fixed on the top of the side wall bracket 1, and a support sleeve 3 is respectively installed on the two ends of the I-shaped steel beam 2, and the side wall bracket 1 is provided with a chute 4, and a support block 5 corresponding to the support sleeve 3 is slidably arranged in the chute 4, and a connecting rod 6 is axially connected between the support sleeve 3 and the corresponding support block 5, and the longitudinal direction in the chute 4 A number of threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com