Air sterilizer, air sterilizing method, device, system and storage medium

An air sterilizer and air disinfection technology, which is applied in air-conditioning systems, air quality improvement, disinfection, etc., can solve problems that affect user experience and reduce the life of the body, and achieve the effects of improving user experience, increasing service life, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

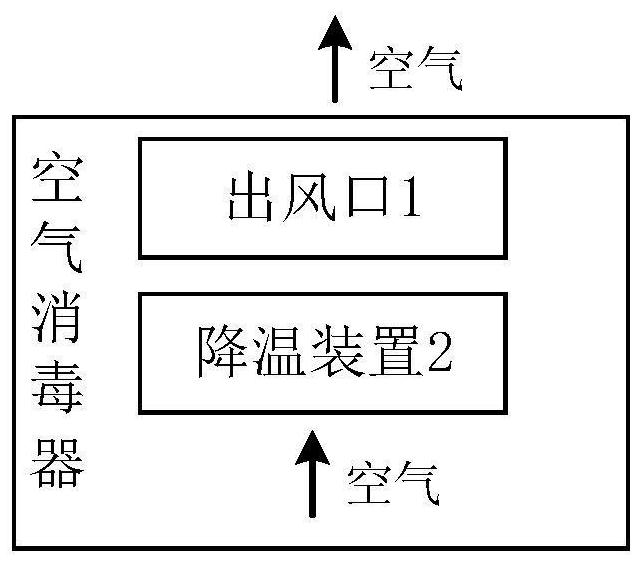

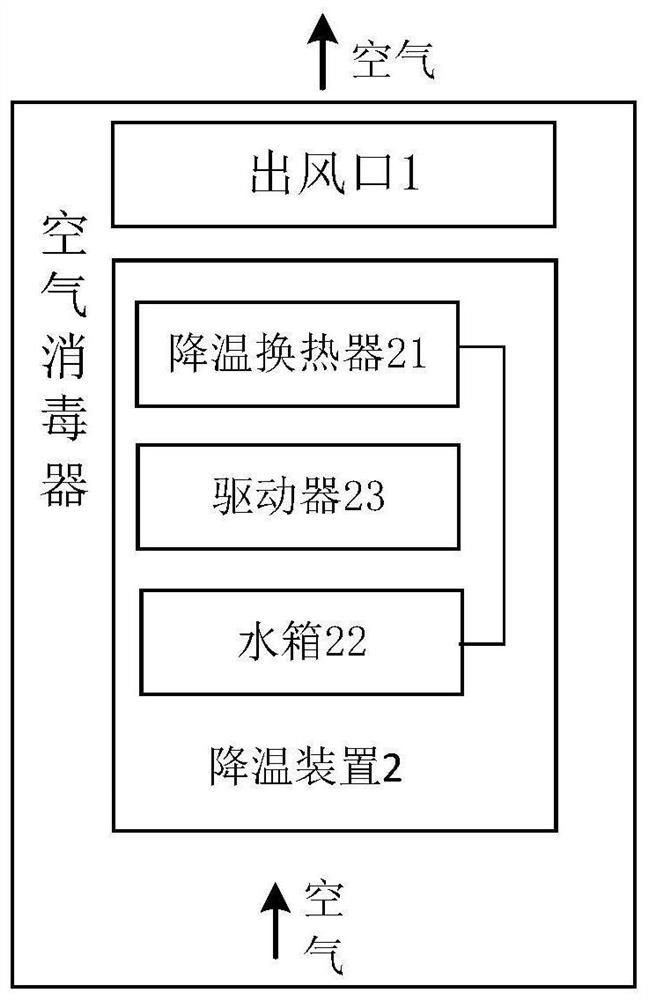

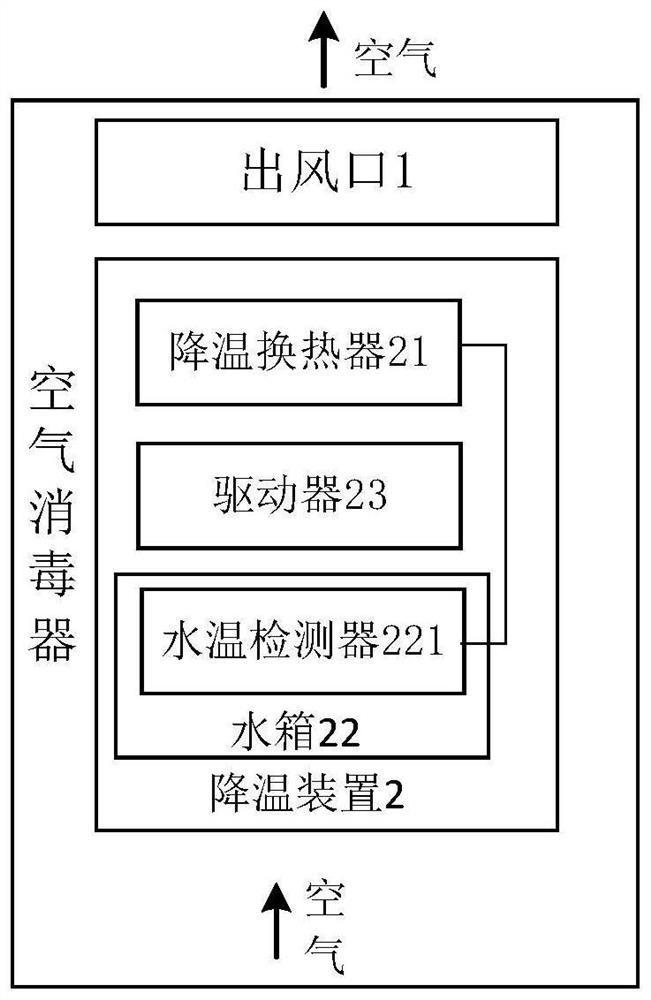

[0039] This embodiment provides an air sterilizer, which can be used for daily disinfection at home, to sterilize and disinfect the air, and realize air purification, such as figure 1 As shown, the air sterilizer includes an air outlet 1 and a cooling device 2 , wherein the cooling device 2 is arranged at the front end of the air outlet 1 .

[0040] Exemplarily, the cooling device 2 is arranged at the front end of the air outlet 1, and is used to reduce the temperature of the high-temperature air generated by the air sterilizer during the sterilization process, so that the temperature of the purified air discharged from the air sterilizer is suitable.

[0041]The air sterilizer provided in this embodiment reduces the outlet air temperature of the air sterilizer by arranging a cooling device at the front end of the air outlet. By reducing the outlet air temperature, it is avoided that the high-temperature air continuously discharged by the air sterilizer during the sterilizatio...

Embodiment 2

[0060] This embodiment provides a kind of air disinfection method, is used for the air sterilizer described in above-mentioned embodiment, carries out sterilization and disinfection to indoor air, purifies air, as Figure 7 Shown, this air disinfection method comprises the steps:

[0061] S21. Obtain the outlet air temperature.

[0062] Exemplarily, the outlet air temperature is the temperature of the purified air discharged after being sterilized by the air sterilizer. The outlet air temperature can be obtained according to the outlet air temperature detector, wherein the outlet air temperature detector can be a temperature sensor or an infrared thermometer. This application does not limit the way of obtaining the outlet air temperature. Those skilled in the art can Determine according to actual needs.

[0063] S22. Determine whether the outlet air temperature exceeds a preset first temperature threshold.

[0064] Exemplarily, the preset first temperature threshold may be ...

Embodiment 3

[0084] This embodiment provides an air disinfection device, which is applied to the air sterilizer described in the above embodiment, and a cooling device is provided at the front end of the air outlet of the air sterilizer, such as Figure 9 shown, including:

[0085] An acquisition module 31, configured to acquire the outlet air temperature. For details, refer to the relevant description of step S21 in the foregoing embodiment, and details are not repeated here.

[0086] A judging module 32, configured to judge whether the outlet air temperature exceeds a preset first temperature threshold. For details, refer to the relevant description of step S22 in the foregoing embodiment, and details are not repeated here.

[0087] The adjustment module 33 is configured to use a cooling device to cool down the temperature of the outlet air when the temperature of the outlet air is greater than the first temperature threshold. For details, refer to the relevant description of step S23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com