Compressor of direct heat pump system and PTC control method

A technology of a heat pump system and control method, which is applied to heating/cooling equipment, vehicle components, transportation and packaging, etc., can solve the problems of long stability time, weak system robustness, and poor comfort of the heat pump system, and achieves good comfort, The system has fast response and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

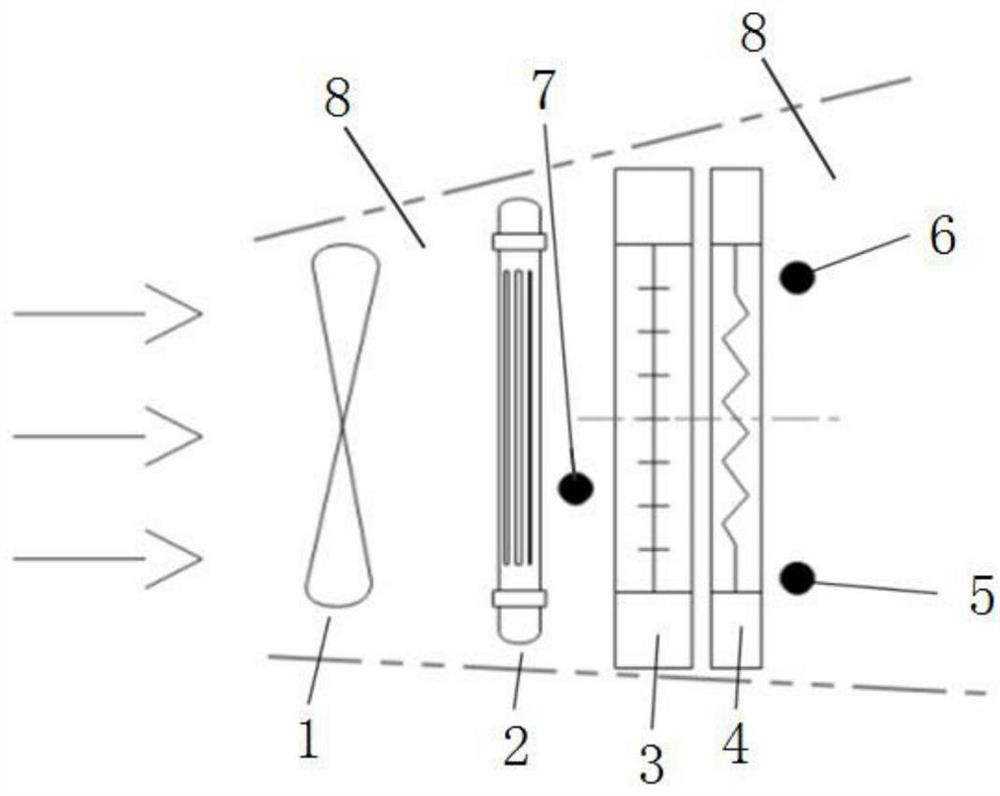

[0025] The specific configuration of the entire system figure 1 , The present invention comprises a blower 1, the evaporator core 2, the heat pump core 3, PTC heater 4, the main drive-side temperature sensor 5, the front passenger side temperature sensor 6, an evaporator temperature sensor 7, the air box 8, the compression heat pump system machine; blower 1, the evaporator core 2, the heat pump core 3, PTC heater 4 are sequentially disposed in the air conditioner casing 8 in the direction of the airflow, an evaporator temperature sensor 7 is arranged within the air box 8 and the evaporation of the core 2, the heat pump core 4 between a body; a main drive-side temperature sensors 5, 6 are front passenger side temperature sensor disposed within the air box 8 and is located in the rear end 4 of the PTC heater.

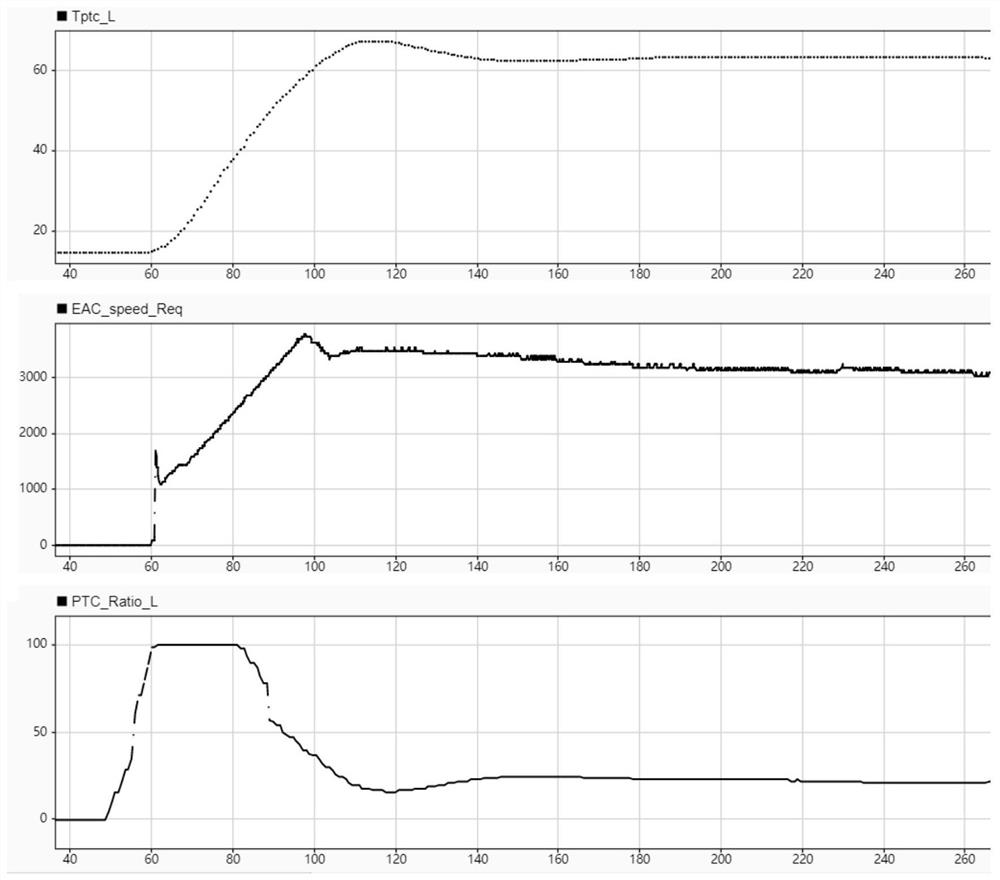

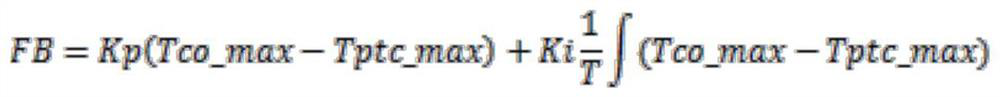

[0026] In the present embodiment, the main goal comfort fujia algorithm of the air temperature are set to 65 degrees, corresponding calculated as follows:

[0027] The heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com