Preparation of a flexible patterned electrode and flexible electronic devices

An electronic equipment and patterning technology, which is applied in equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, circuits, etc., can solve problems such as limited application scope, single electrode pattern, and increased cost, and achieve expanded use. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

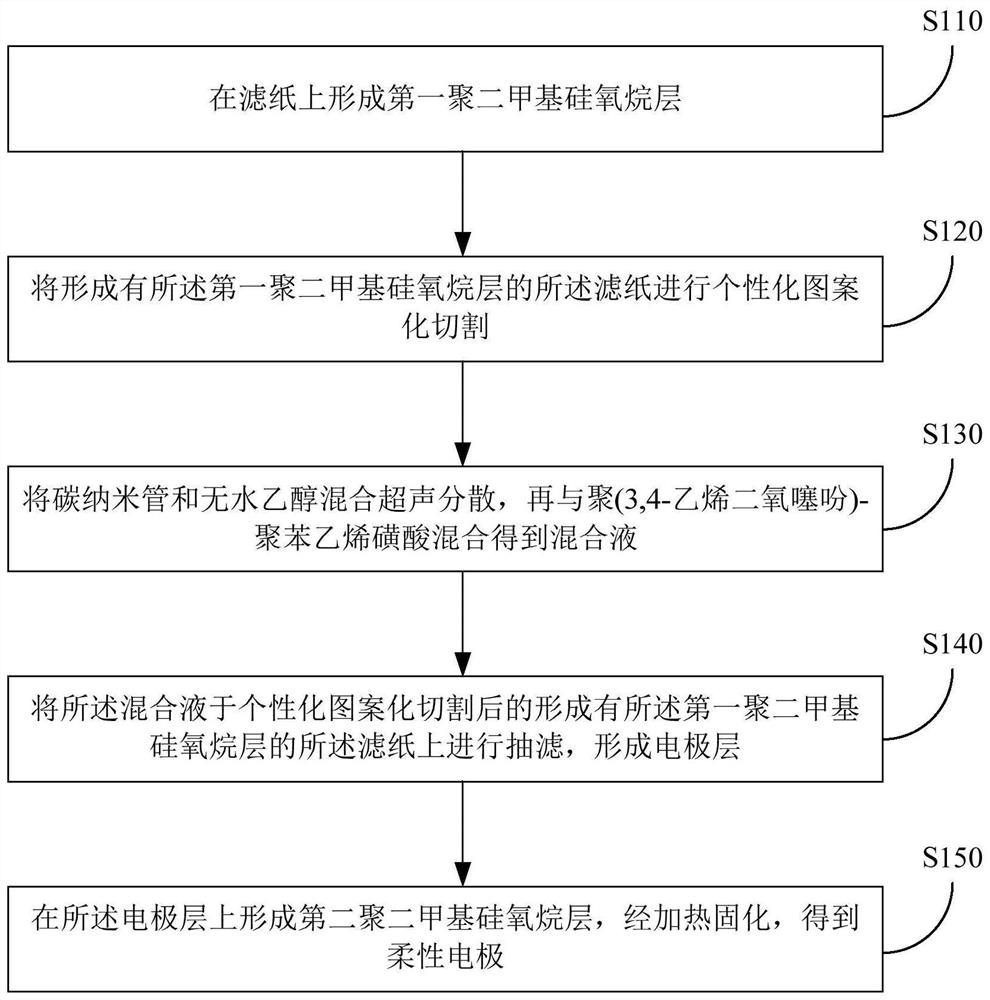

[0047] like figure 1 As shown, the preparation method of the flexible electrode provided by one embodiment of the present invention includes the following steps:

[0048] Step S110: forming a first polydimethylsiloxane layer on the filter paper.

[0049] In one embodiment, forming the first polydimethylsiloxane layer on the filter paper includes the following steps: coating a solution containing polydimethylsiloxane and a curing agent on the filter paper, drying, and forming The first polydimethylsiloxane layer.

[0050] In one of the embodiments, the method of coating the solution containing polydimethylsiloxane and curing agent on the filter paper is spin coating, the spin coating speed is 400-700rpm, and the spin coating time is 8s-15s, The thickness of the first polydimethylsiloxane layer is 50-200 microns.

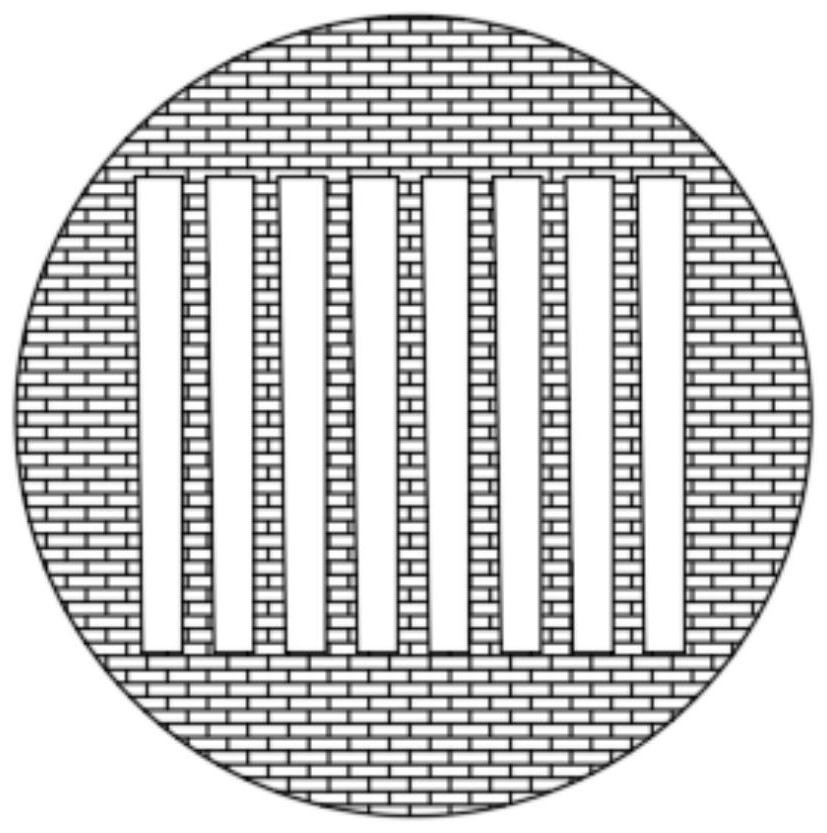

[0051] Step S120: Carry out personalized pattern cutting on the filter paper formed with the first polydimethylsiloxane layer.

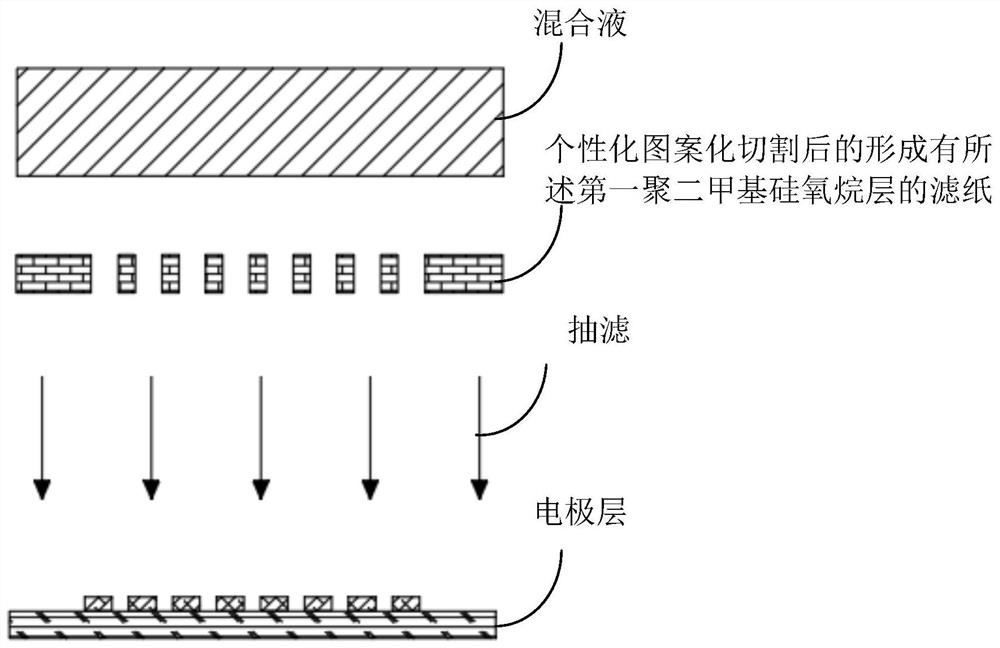

[0052] Specifically, the cutting ...

Embodiment 1

[0070] The preparation process of the tactile sensor of this implementation is as follows:

[0071] (1) The solution containing polydimethylsiloxane and curing agent was spin-coated on filter paper at 400 rpm, and dried to form the first polydimethylsiloxane layer.

[0072] (2) Carry out personalized pattern cutting on the filter paper formed with the first polydimethylsiloxane layer.

[0073] (3) In an ice bath environment, the carbon nanotubes and the absolute ethanol are mixed at a solid-to-liquid ratio of 0.004g: 80ml, and the carbon nanotubes are mixed with the absolute ethanol at 0°C Ultrasonic dispersion to obtain a mixture, the mixture was centrifuged, and the supernatant was taken to obtain a dispersion of the carbon nanotubes, and the poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid was mixed with the The volume ratio of the dispersion of the carbon nanotubes is 5ml and mixed, and then ultrasonically dispersed to obtain the mixed solution;

[0074] (4) Las...

Embodiment 2

[0077] The preparation process of the flexible electrode of this embodiment is roughly the same as that of Embodiment 1, except that the carbon nanotubes in step (2) of this embodiment are multi-walled carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap