Semiconductor chip module

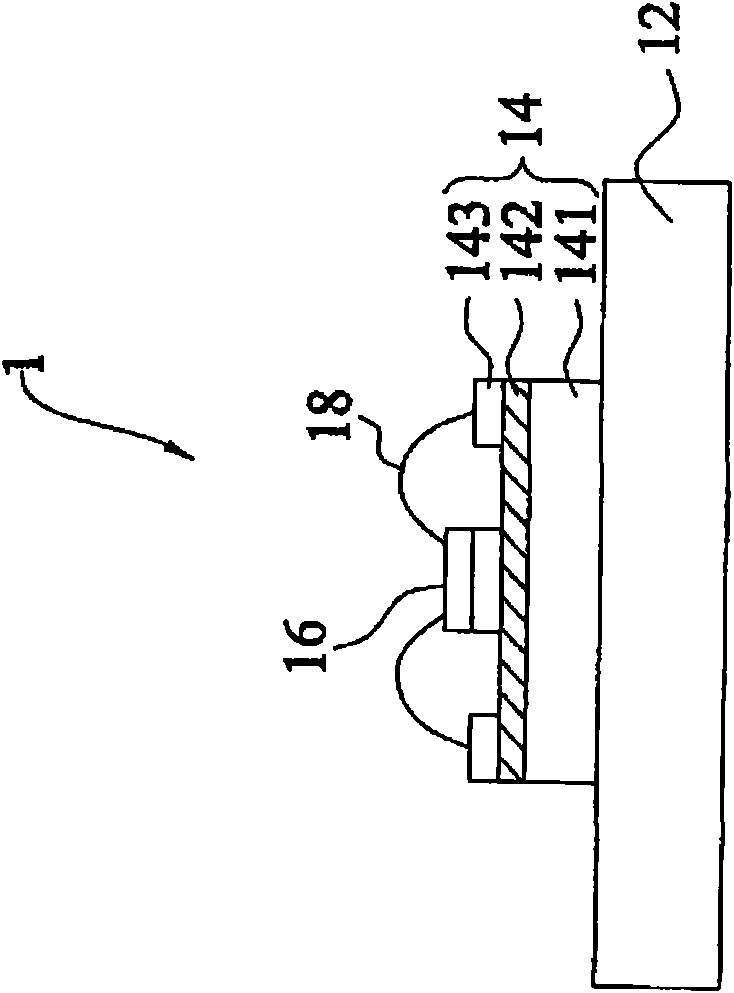

A chip module and semiconductor technology, which is applied to semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of poor heat dissipation efficiency, poor efficiency of the base 12, and high manufacturing cost of the solar chip module 1, and saves energy. The effect of manufacturing cost and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to further understand the purpose, structure, features, and functions of the present invention, the detailed description of the accompanying examples is as follows.

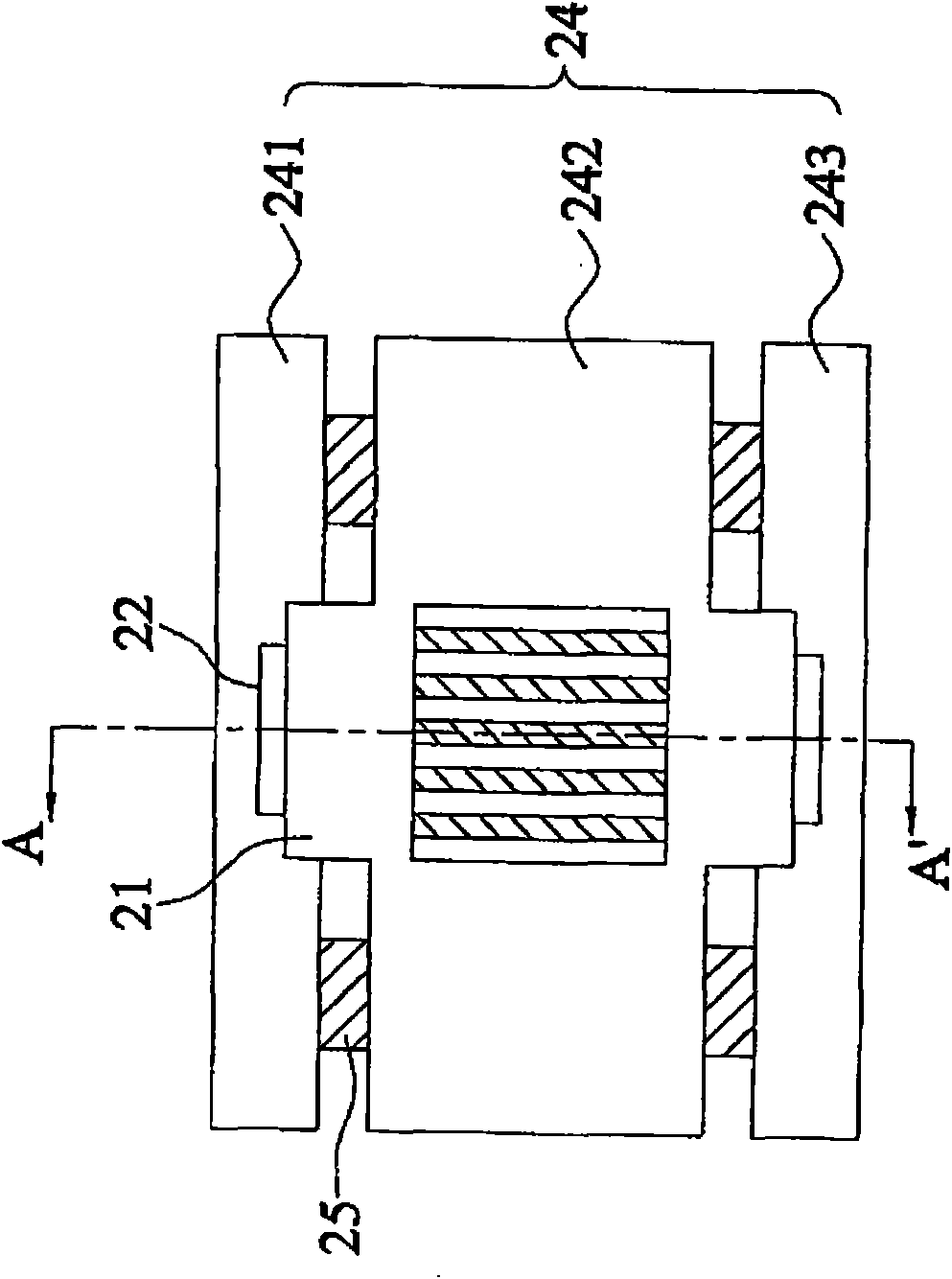

[0060] Figure 2A A top view of the semiconductor chip module 2 of the present invention is shown according to the first embodiment. Figure 2B for the semiconductor chip module 2 along the Figure 2A A cross-sectional view of the dotted line A-A'. image 3 It is an exploded view of the structure of the conductive frame 21 , the flexible cable 22 and the semiconductor chip 23 of the semiconductor chip module 2 .

[0061] As shown in the figure, the semiconductor chip module 2 includes a conductive frame 21 , a flexible cable 22 , a semiconductor chip 23 and a heat dissipation structure 24 . The semiconductor chip 23 defines a front side 23a and a back side 23b. The semiconductor chip 23 has a first electrode 231 and a second electrode 232 located on the front side 23a and the back side 23b res...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap