High-efficiency arc extinguishing relay

A relay and arc extinguishing technology, which is applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve the corrosion of the contact between the moving contact and the static contact, and the arc is easy to hit the inner wall of the insulating cover and rebound to the moving and static contacts , moving reed and other parts, distance reduction and other problems, to achieve the effect of good arc extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

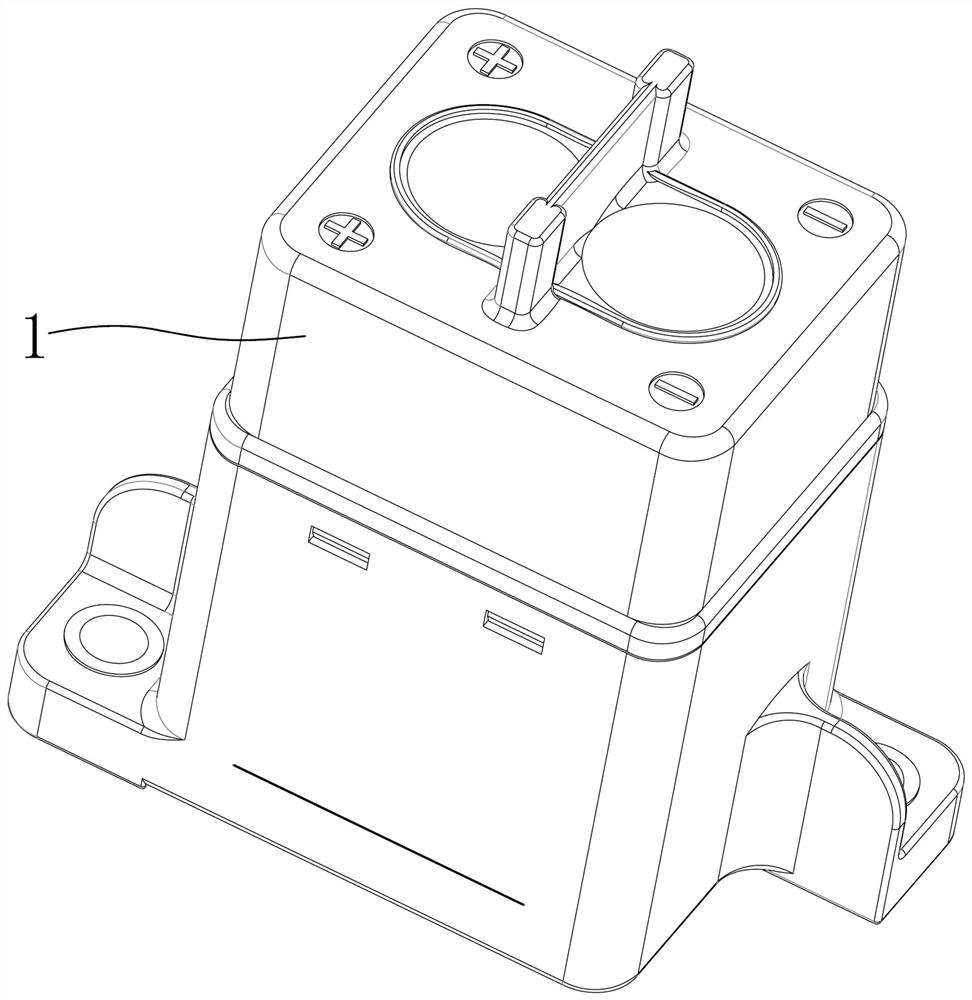

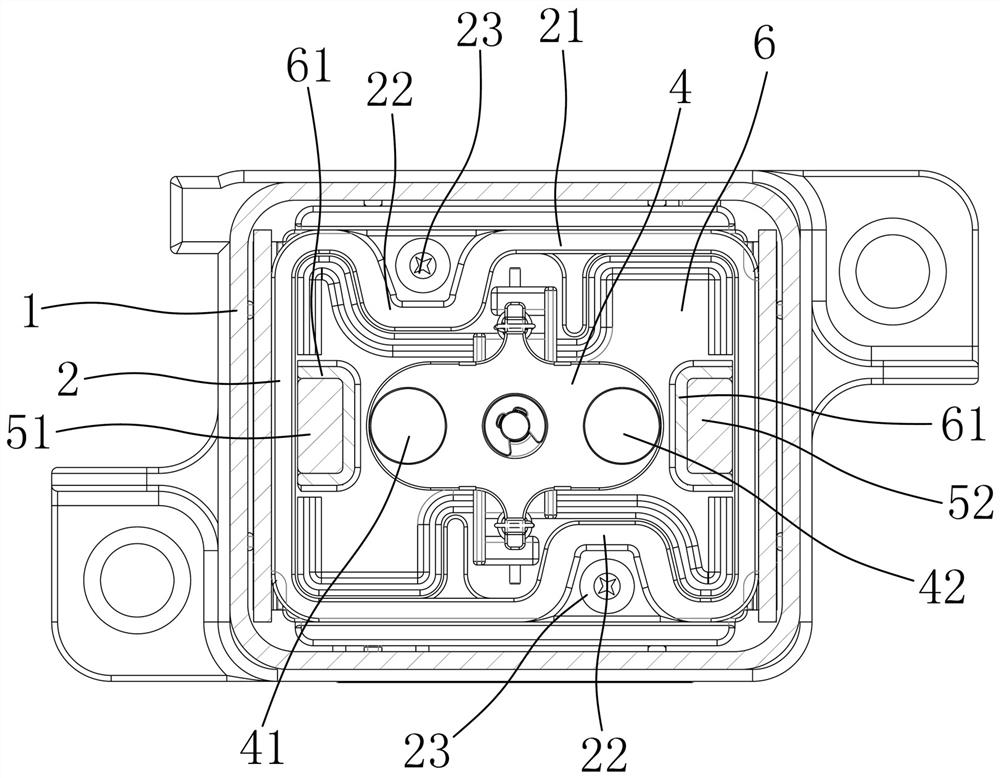

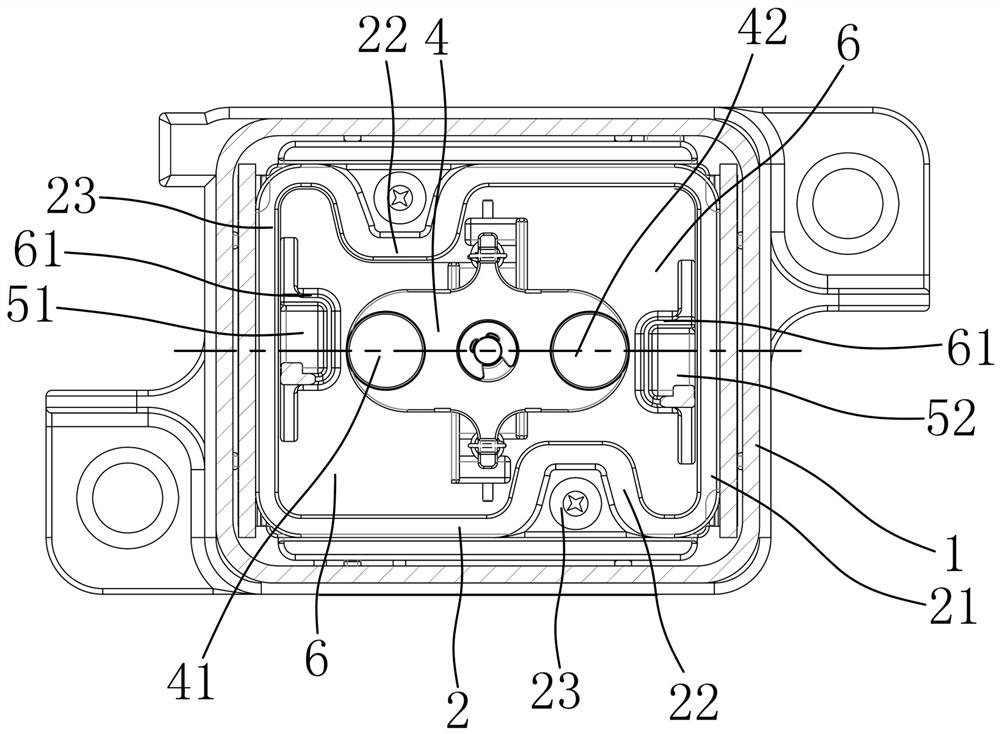

[0028] Depend on figure 1 , figure 2 As shown, a high-efficiency arc-extinguishing relay of the present invention includes an outer shell 1, and an insulating cover 2 and a yoke iron plate are arranged inside the outer shell 1, and the insulating cover 2 and the yoke iron plate 3 are formed to accommodate moving contacts and static contacts. point chamber, the movable contact includes a left movable contact 41 and a right movable contact 42 fixed on the left and right ends of the movable reed 4, and the static contact includes a left static contact corresponding to the left movable contact 41 and a right movable contact. Point 42 corresponds to the right static contact. The magnets used to blow the arc generated by the breaking of the dynamic and static contacts are all arranged in the chamber, the magnets include a first magnet 51 and a second magnet 52, and the first magnet 51 and the second magnet 52 are respectively located in Moving reed 4 left and right sides.

[002...

Embodiment 2

[0033] Depend on figure 1 , image 3 As shown, the difference between this embodiment and the first embodiment is that the axis of the first magnet 51 along the left-right direction and the axis of the second magnet 52 along the left-right direction deviate from the axis of the moving reed 4 along the left-right direction. Wherein, one inner protrusion 22 is located at the left rear of the insulating cover, and the other inner protrusion 22 is located at the right front of the insulating cover, and the first magnetic steel 51 moves to the left inner protrusion to deviate from the axis of the moving reed 4 along the left-right direction. , the second magnetic steel 52 protrudes inwardly and moves to the right to deviate from the axis of the moving reed 4 along the left-right direction.

[0034] In this embodiment, the moving track of the arc close to the inner convex side is longer, so as to improve the arc extinguishing effect.

Embodiment 3

[0036] Depend on figure 1 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the magnets also include a third magnet 53 and a fourth magnet 54, and the third magnet 53 and the fourth magnet 54 are respectively located at the front and rear sides of the moving reed 4 One side of it; the cross-sectional shape of the inner protrusion 22 in embodiment 3 is L-shaped, and the two inner protrusions 22 are located at the opposite corners of the square insulating cover 2 .

[0037] In this embodiment, the insulating cover can be made larger as much as possible while keeping the shape and size of the outer casing of the relay unchanged, so that the distance between the circumferential inner wall of the insulating cover and the dynamic and static contacts is longer, so that the arc will pass through a longer distance. Only when moving can hit the circumferential inner wall of the insulating cover, so as to eliminate the energy of the arc as much as possi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com