Cylindrical workpiece polishing machine

A circular workpiece and cylindrical technology is applied in the field of cylindrical workpiece polishing machines, which can solve the problems of increasing labor intensity of workers, high labor intensity, and inability to guarantee accuracy, etc., so as to reduce labor intensity of workers, increase polishing range, and improve polishing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

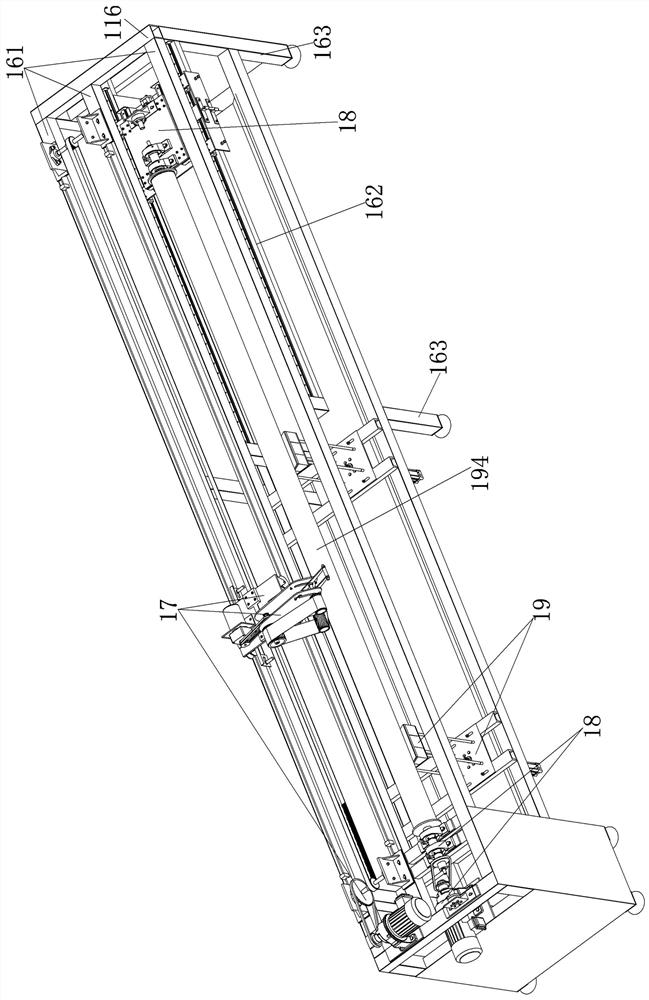

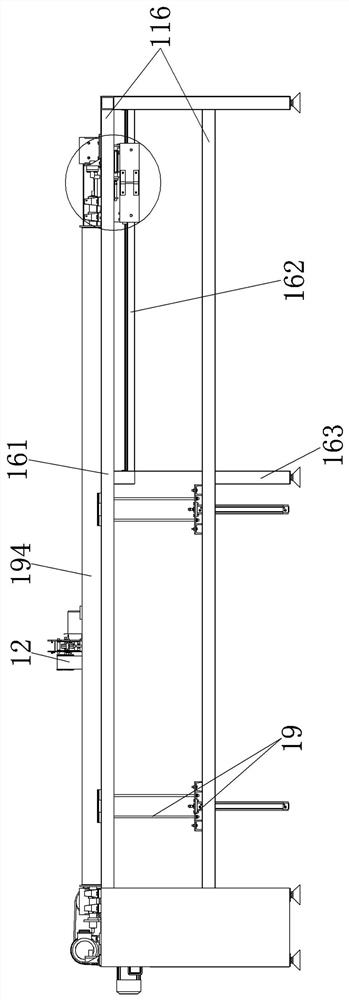

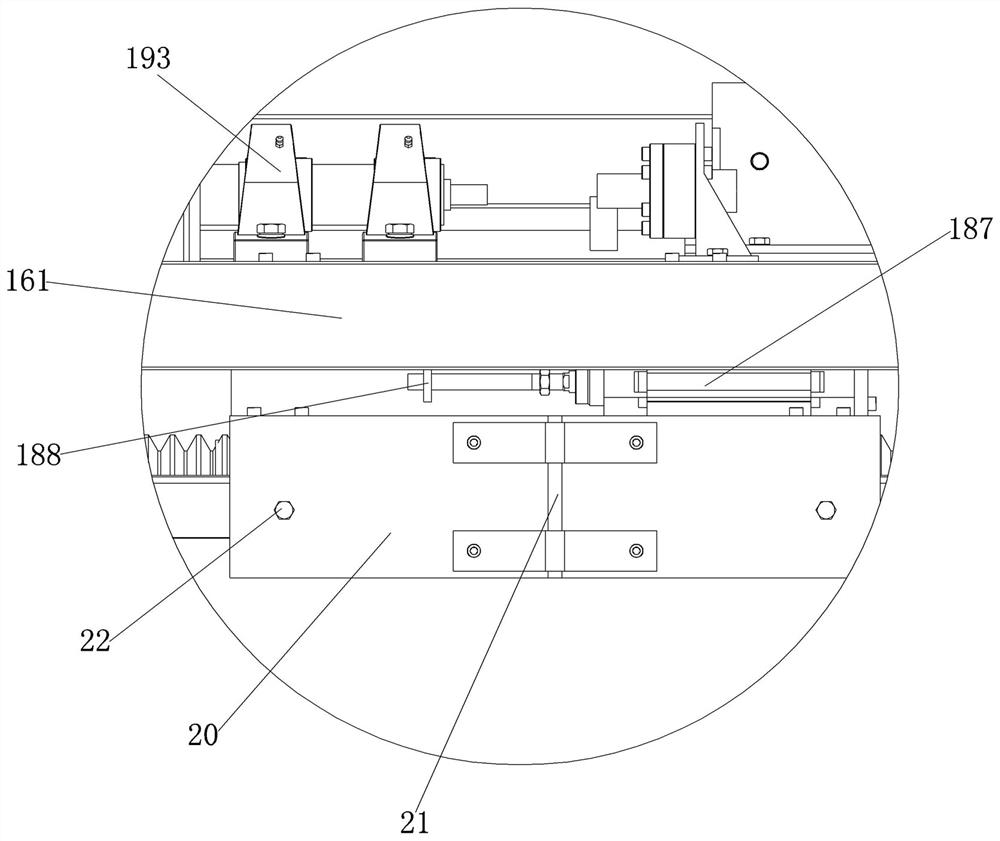

[0047] Embodiment 1, referring to the accompanying drawings (1-22) of the specification, a cylindrical workpiece polishing machine includes a bracket, a reciprocating polishing device, and a cylindrical workpiece driving device; the bracket is a cuboid bracket welded by several square steel pipes, The upper end of the bracket is connected by three upper beams, and the lower end of the two upper beams on the outer side is provided with two identical slide rail support beams, and the bracket is provided with several outriggers downward;

[0048] The reciprocating polishing device is installed on the inner side of the bracket. A reciprocating polishing device for circular workpieces includes a mobile platform, a polishing belt tensioning device, a track, and a reciprocating drive device. The track is two corners arranged side by side. Iron, the reciprocating driving device is located at both ends of the track, the reciprocating driving device includes a bearing seat, a driving bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com