Glove gum dipping production line and control method thereof

A production line and dipping technology, which is applied to the glove dipping production line and its control field, can solve problems such as inability to meet protective gloves, and achieve the effects of strong practicability, low cost and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

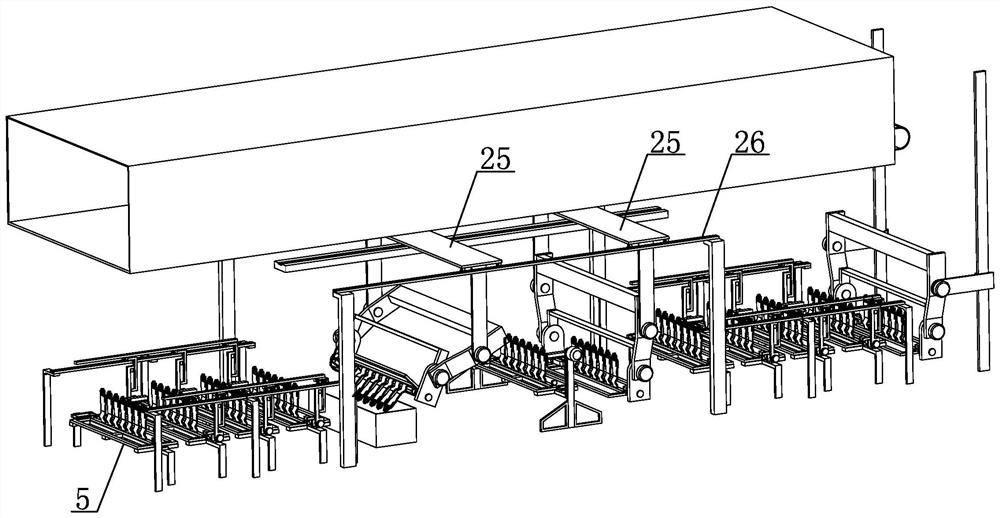

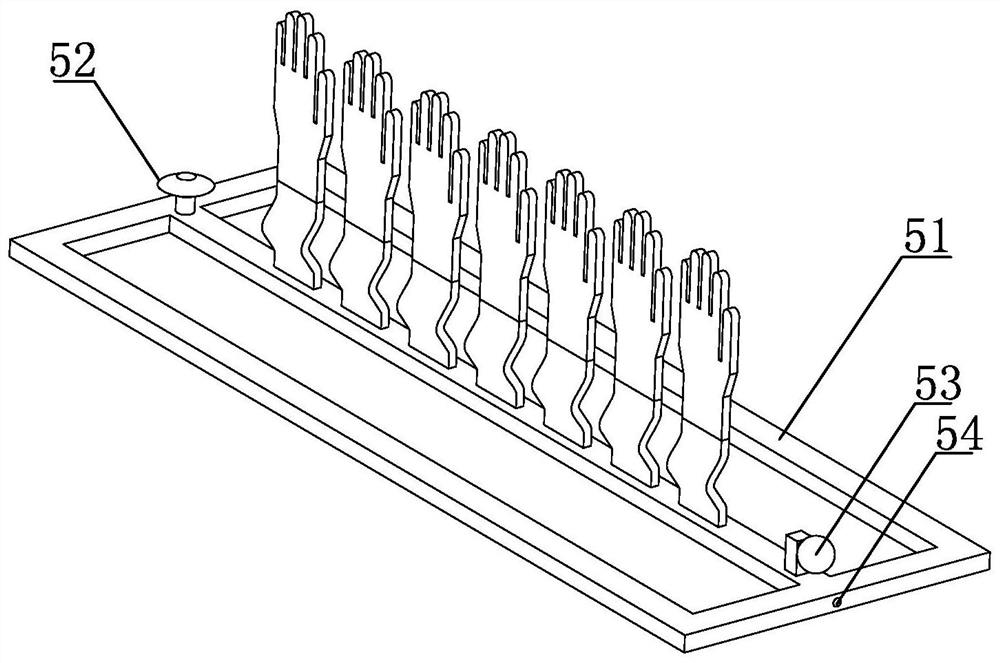

[0048] Present embodiment proposes a kind of glove dipping production line, as figure 1 As shown, the production line is used for gloves that need to be dipped once. From the starting point to the end of the production line, it includes a clamping translation device 1, a dipping device 2, a clamping translation device 1 and a lifting transfer device 3. The clamping translation device 1 and There is also a drying box 4 above the dipping device 2, and the three-dimensional design that the drying box 4 is arranged above the clamping translation device 1 and the dipping device 2 can effectively save the use area in the factory building. The drying box 4 in this embodiment is a conventional device in the field of protective gloves production, so it will not be described in detail in this application. The drying box 4 of this kind is provided with a conveyor belt 41 for transferring the hand mold frame 5 .

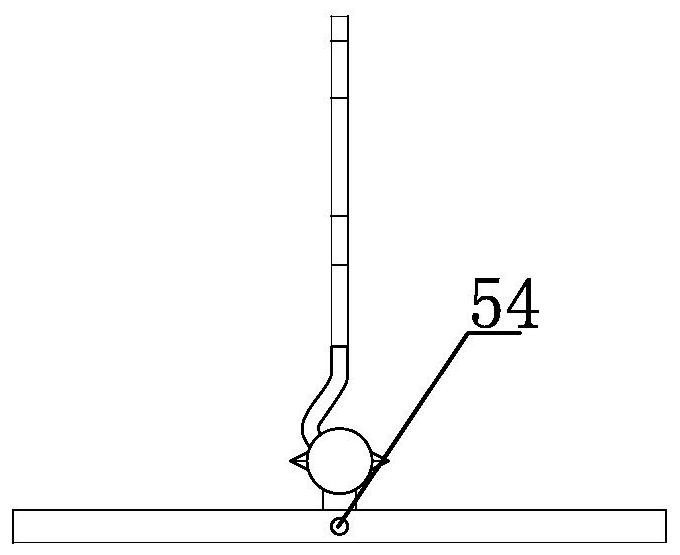

[0049] Such as Figures 2 to 4 As shown, the production line also includes...

Embodiment 2

[0064] The principle of this embodiment is the same as that of Embodiment 1. The difference is that this embodiment can be used for protective gloves that require secondary dipping. The production line of this embodiment includes clamping translation device 1, dipping device 2, Clamping translation device 1, dipping device 2, clamping translation device 1 and lifting transfer device 3. It can be seen that when N times of dipping are required, the production line needs to be equipped with N dipping devices 2 and N+1 clamping translation devices 1, which also reflects that the production line has the advantages of flexible layout and wide application range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com