Split type guide wheel, tramcar and wheel core replacement method

A guide wheel, split technology, applied in the field of rail vehicles, can solve the problems of large running noise of the guide wheel, inconvenient monitoring of wear amount, high risk of derailment, etc., to avoid derailment, improve contact reliability, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

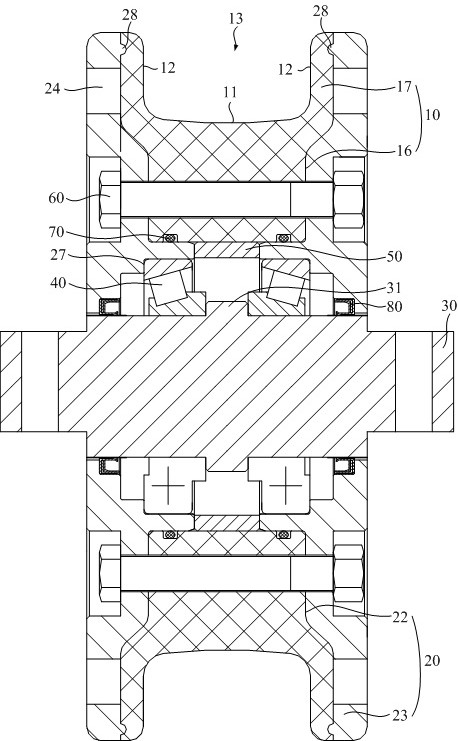

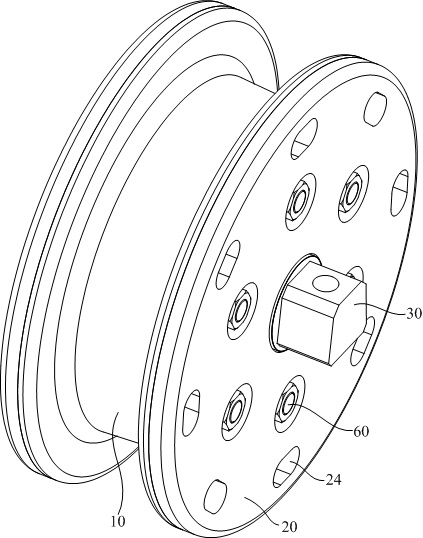

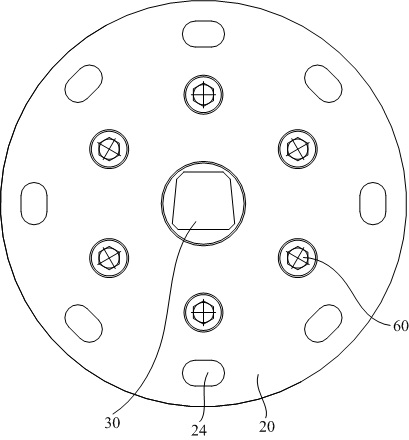

[0043] The split guide wheel in this embodiment can be applied to trams, refer to figure 1 and figure 2 , which mainly includes wheel core 10, end cover 20, wheel axle 30 and other parts.

[0044] refer to Figure 4 , the wheel core 10 is a plastic part, the wheel core 10 has a circumferential tread 11 and a disc-shaped rim 12 formed on both sides of the circumferential tread 11, the circumferential tread 11 and the two rims 12 form a groove 13, the circumferential tread 11 and the wheel The rims 12 are perpendicular to each other, and the wheel core 10 is provided with a first shaft hole 14 along its axial direction.

[0045] The end cap 20 has two, referring to Figure 5 , The end caps 20 are detachably arranged on both sides of the wheel core 10 , and the end caps 20 are provided with a second shaft hole 21 .

[0046] The wheel shaft 30 is passed through the first shaft hole 14 and the second shaft hole 21 to assemble the wheel core 10 and the two end caps 20 as a whol...

Embodiment 2

[0064] This embodiment discloses a tram, which includes the split guide wheel disclosed in Embodiment 1.

Embodiment 3

[0066] This embodiment discloses a wheel core replacement method applied to the split guide wheel of Embodiment 1, including:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com