A construction method for the steel-concrete transition section of a separated railway bridge

A construction method and separate technology, applied in bridges, bridge construction, bridge materials, etc., can solve the problems of heavy weight and inability to meet the use requirements, and achieve the effect of fast hoisting and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

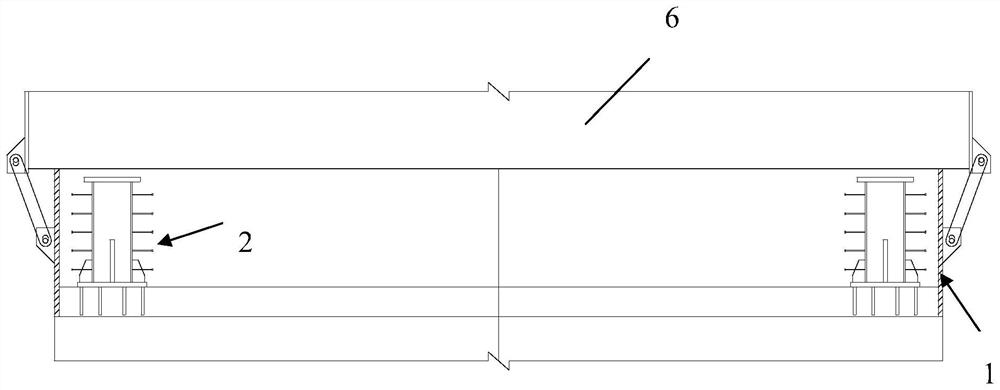

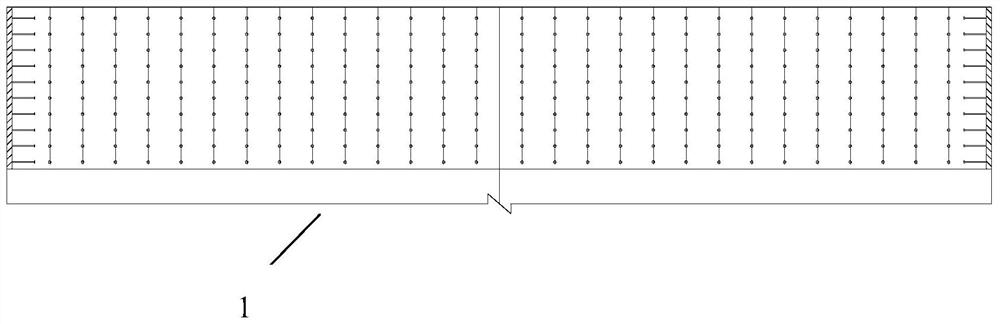

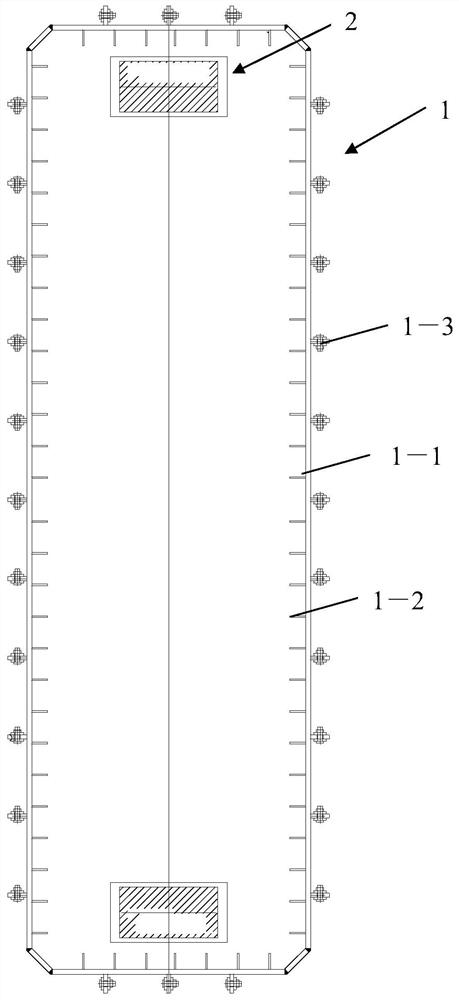

[0024] like Figure 1-Figure 5 As shown, the separation type railway bridge steel-concrete transition section structure construction method provided by the invention comprises the following steps carried out in order:

[0025] 1) According to the design requirements, the outsourcing steel plate 1 and the temporary steel backing stone 2 are produced by factory method, and then transported to the construction site; the outsourcing steel plate 1 includes the steel box 1-1, the shear plate 1-2 and the connecting piece 1- 3. The steel casing 1-1 is a cuboid box structure with open upper and lower ends. The middle and upper parts of the inner surface protrude outwards to form a plurality of vertically arranged shear plates 1-2. The middle part of the outer surface is separated by a distance of There is a circle of connectors 1-3; the temporary ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com