Plug-in mounting power assisting device with locking function

A technology of booster and plug-in, which is applied to fixtures, mechanical equipment, etc., can solve the problems of panel space occupation of components and affect the appearance of components, and achieve the effects of quick plug-in operation, labor-saving booster operation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

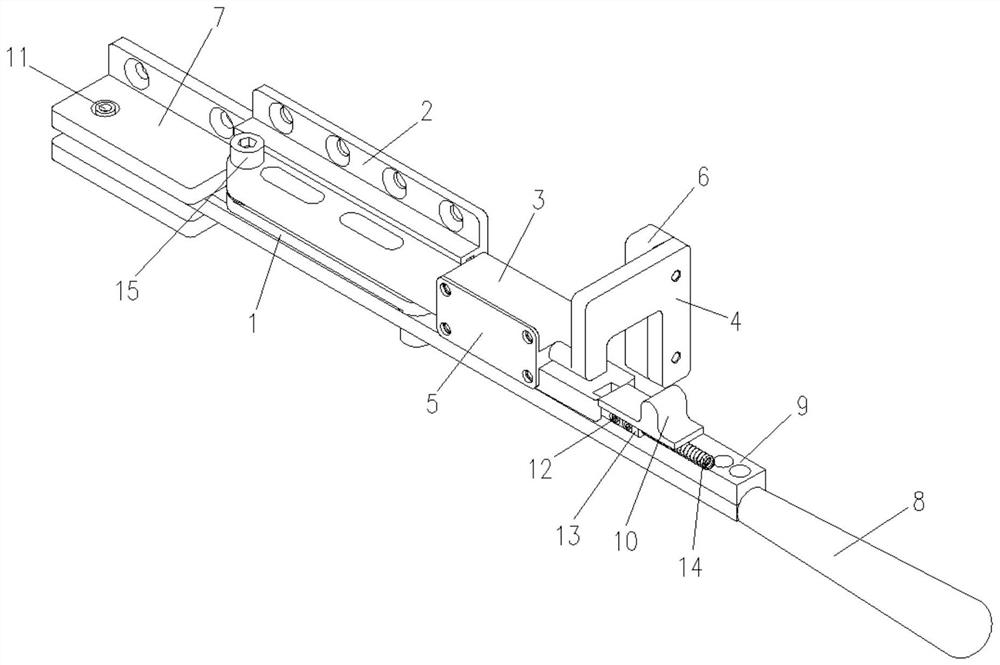

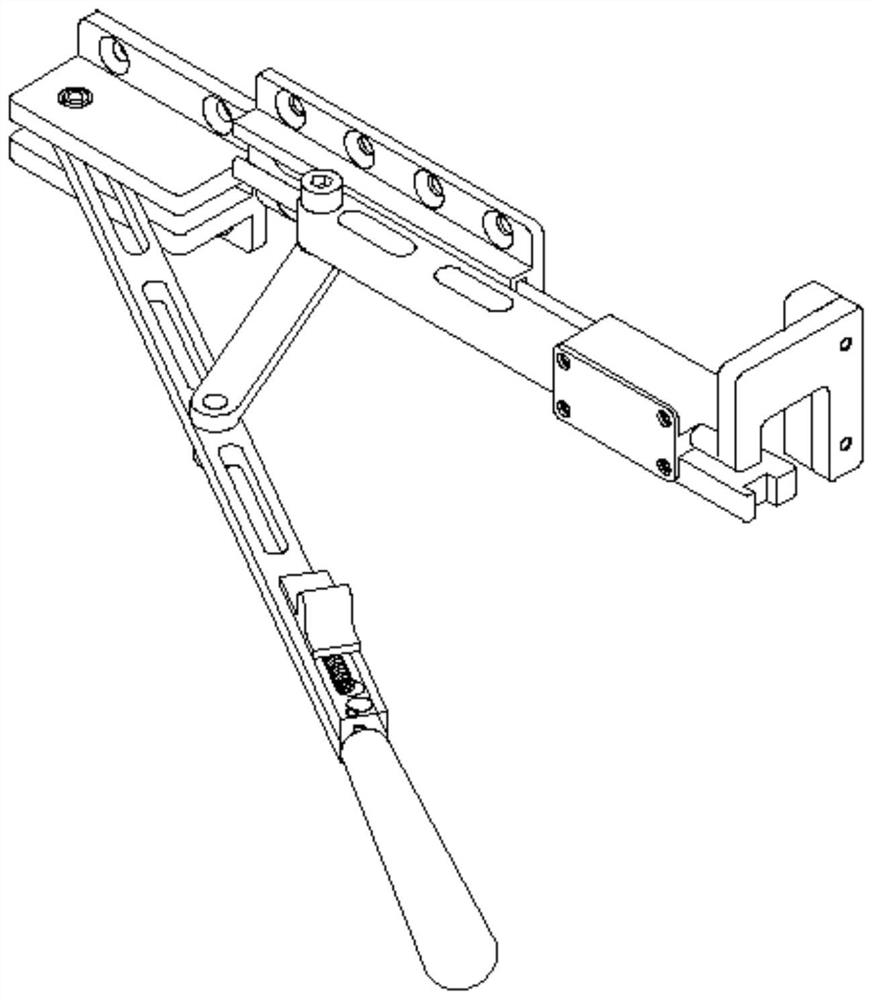

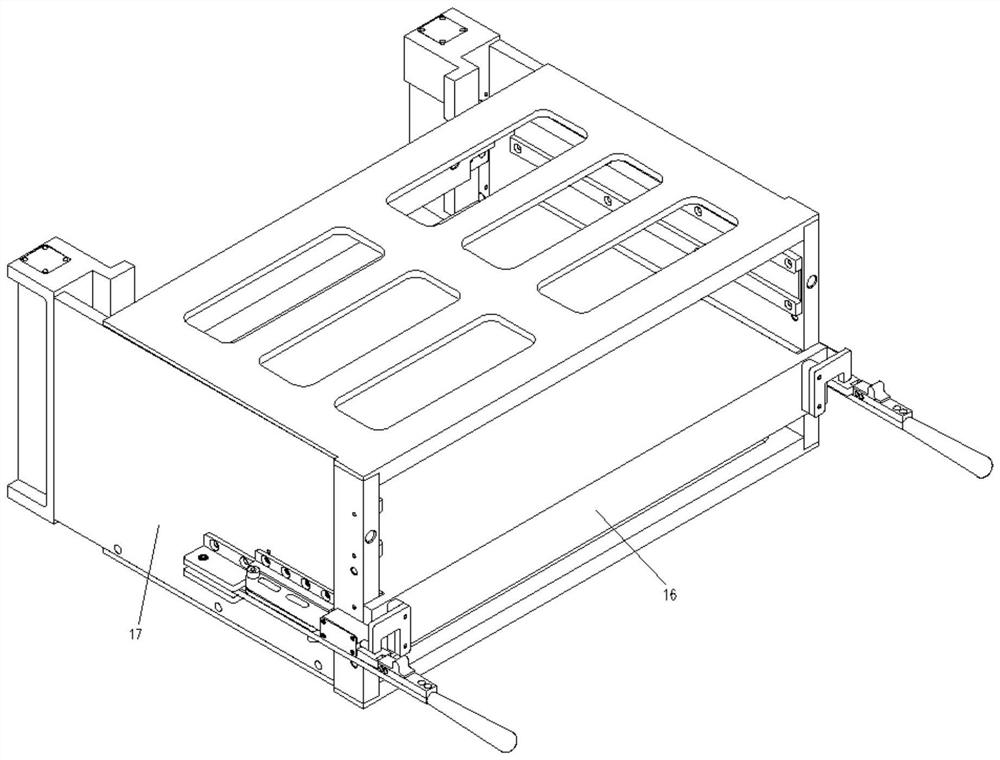

[0013] combine Figure 1-Figure 3 , a locking mechanism with a booster function, including a connecting rod 1, a guide rail 2, a slide bar 3, a handle 8 and a base 7, and the handle 8 includes a lock cap 9, a shift block 10, a latch 12, a lock hook 13 and a push spring 14. The slide bar 3 includes a pressing piece 4, a cover plate 5 and a backing plate 6. The handle 8 and the base 7 are riveted through the bolt 11 to form a rotating pair. The lock hook 13 presses the push spring 14 into the lock cap 9, pushing To a certain position, the shifting block 10 is inserted into the lock hook 13 through the waist-shaped hole on the upper end surface of the lock cap 9, riveted with the latch 12, and the push spring 14 is always kept in a compressed state, and the pressing part 4 is inserted into the semicircular guide of the slide bar 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com