Structure for increasing one-way gain through angular side pumping and implementation method

A one-way gain and side pumping technology, which is applied in the application of laser technology and the field of solid-state lasers, can solve the problems that the laser system cannot be guaranteed to be small in size and light in weight, affects the quality of the laser output beam, and the uneven distribution of pump light, etc., and achieves one-way Gain boost, increase one-way gain, and increase the effect of absorbing pump power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

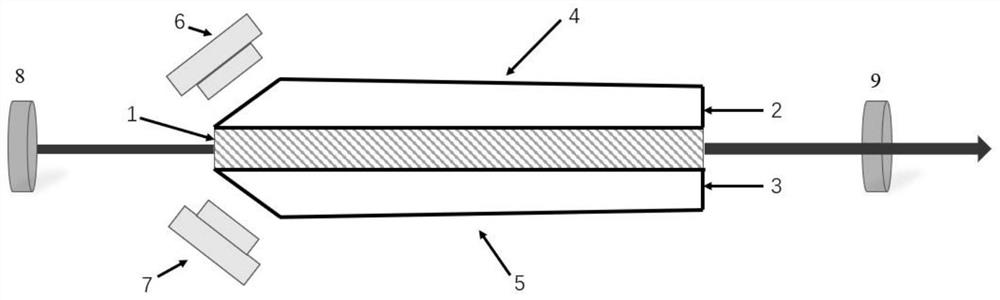

[0024] The structure of this embodiment is figure 1 Shown, where: 1. gain medium; 2. non-absorptive cladding; 4, 5. cladding coating reflective surface with cut corners; 6, 7. pump module; 8. total-reflecting cavity mirror; 9. Output cavity mirror. The pump light generated by the pump modules 6 and 7 is incident perpendicular to the angled pump surface, and is injected obliquely into the gain medium 1, and when it is transmitted to the non-absorbing cladding layers 2 and 3, there are many angled coating reflection surfaces on the back side. Times reflection. The pump light passes through the gain medium 1 many times to increase the absorption length and realize the improvement of the single-pass gain of the laser.

[0025] The preparation process of the structure of this embodiment is as follows:

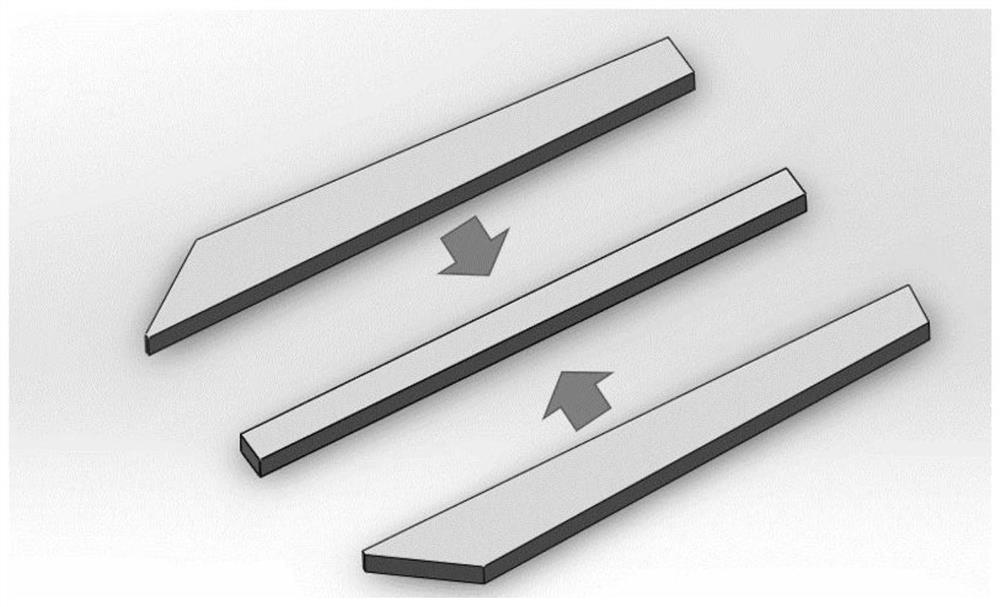

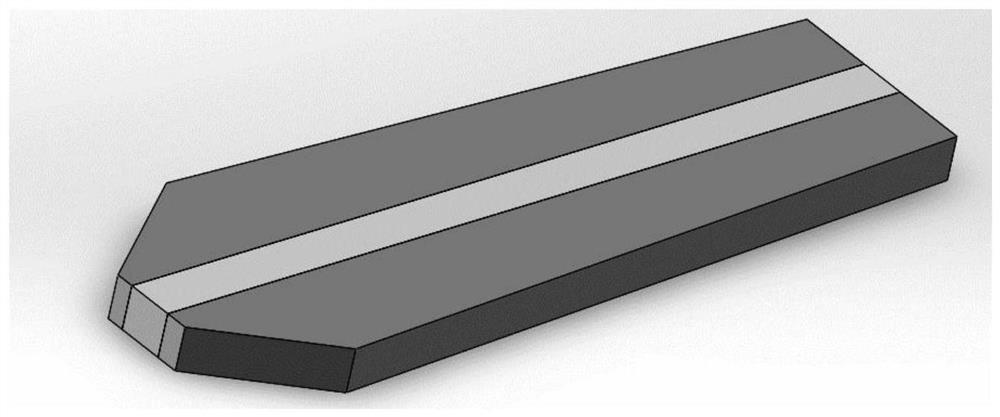

[0026] According to the designed size, wire-cut the blanks of the laser gain medium, absorbing material and cladding material to obtain the gain medium of the required size, and then g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com