Garment peaked collar separate design original number cutting method

An original number cutting method and clothing technology, applied in the field of clothing design, can solve the problems of time-consuming, poor clothing comfort, and low cutting precision, and achieve the effects of good wearing comfort, high clothing precision, and long time-consuming solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

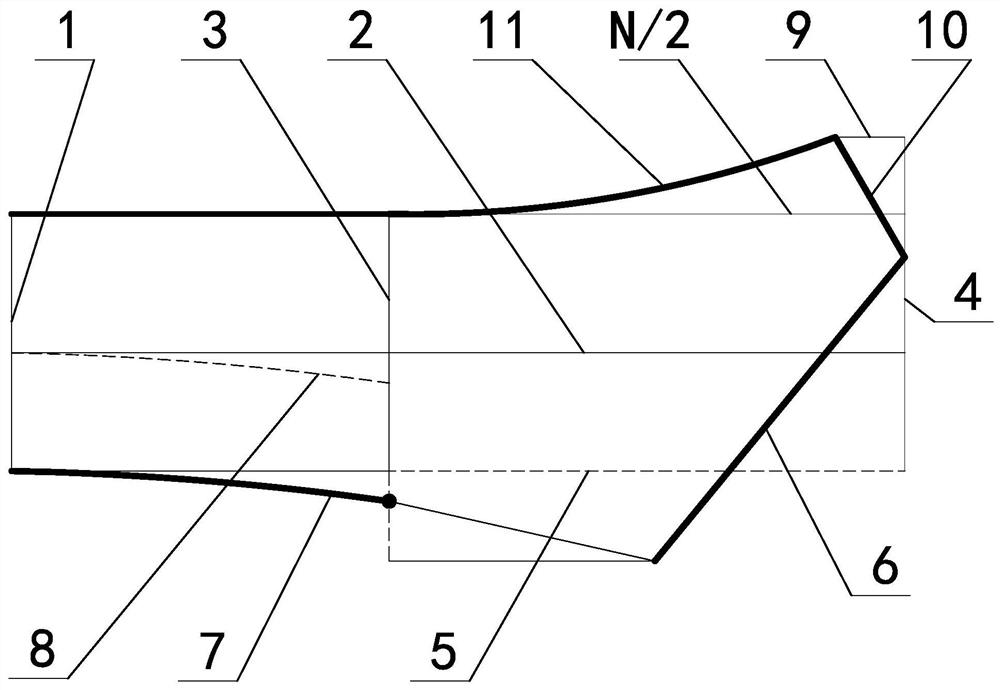

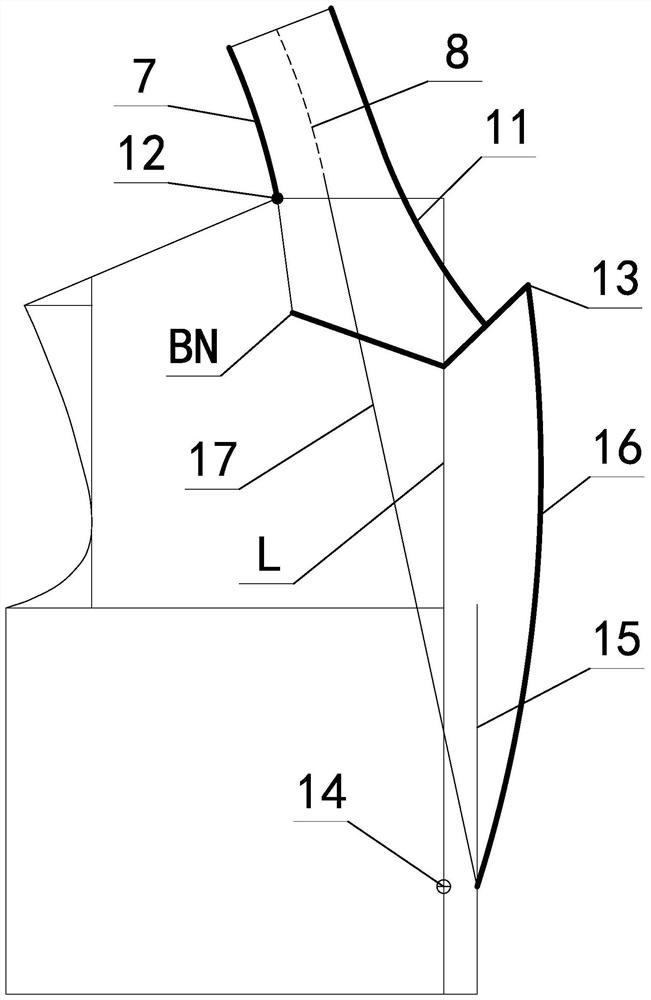

[0023] in as figure 1 , figure 2 In the illustrated embodiment 1, a method of cutting out the original number of the design of the lapel of a garment separately comprises the following steps:

[0024] a. Determine the collar length N, upper collar middle width, lower collar middle width, collar width, stack door width and the original number of relevant basic clothing according to the clothing style; the original number of clothing here refers to the specifications of the clothing determined before the clothing design Numerical values are conventional clothing parameters, such as the raw data of clothing length, bust circumference, waist circumference, and shoulder width.

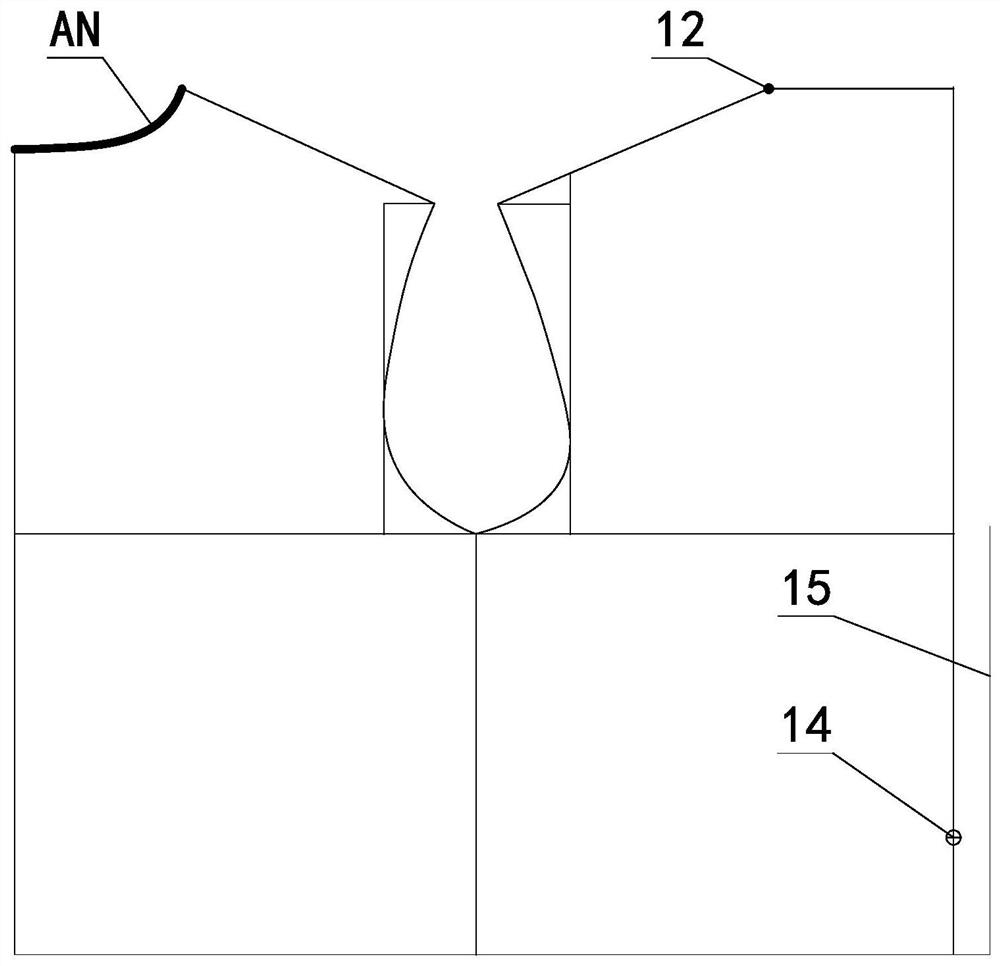

[0025] b. After the design of the front and rear parts is completed, measure the length AN of the half-back collar line on the rear part; (see image 3 , the left side of the figure is the half back piece of the garment, the right side is the front piece of the garment, and the length AN of the half ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com