Hammer combination device

A combined device and hammer technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of manpower consumption, cumbersome operation process, affecting work efficiency, etc., and achieve the effect of saving manpower and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

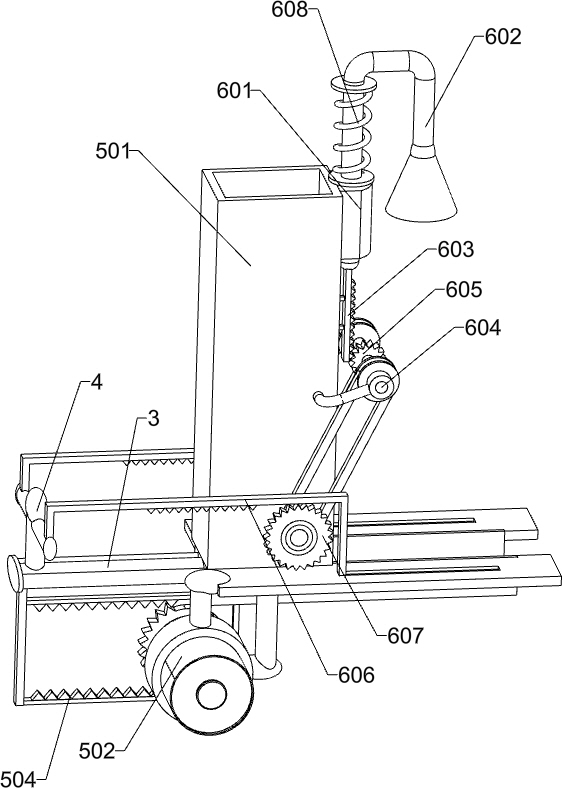

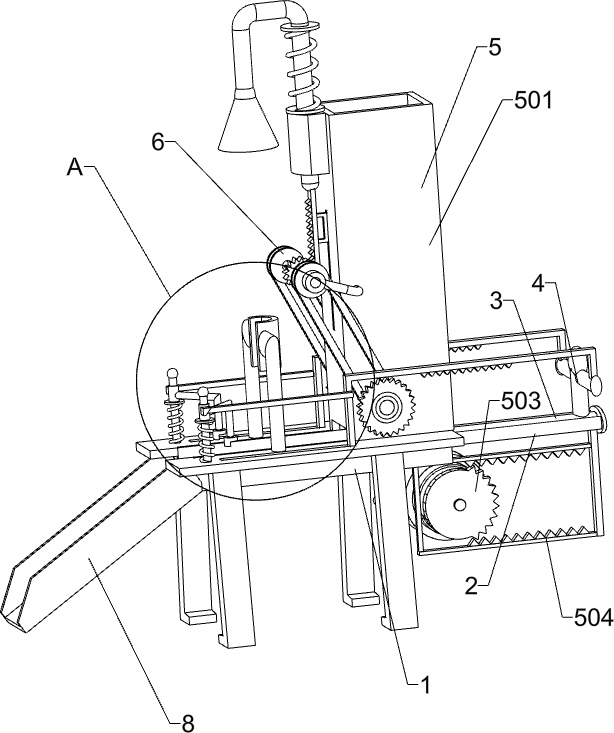

[0023] A hammer combination device such as Figure 1-2 As shown, it includes a grooved plate 1, a guide frame 2, a push rod 3 and a connecting rod 4, the right side of the groove plate 1 is connected with a guide frame 2, the guide frame 2 is slidably connected with a push rod 3, and the top of the push rod 3 Connected with connecting rod 4, also includes unloading mechanism 5 and down-pressing mechanism 6, is provided with unloading mechanism 5 between groove plate 1 and push rod 3, and unloading mechanism 5 is provided with down-pressing mechanism 6.

[0024] The blanking mechanism 5 includes a material frame 501, a reduction motor 502, a sector gear 503 and a back-shaped rack 504. The right side of the groove plate 1 top is connected with the material frame 501, and the bottom right side of the groove plate 1 is equipped with a reduction motor 502. The reduction motor The output shaft of 502 is connected with a sector gear 503 , and the bottom of the push rod 3 is connected...

Embodiment 2

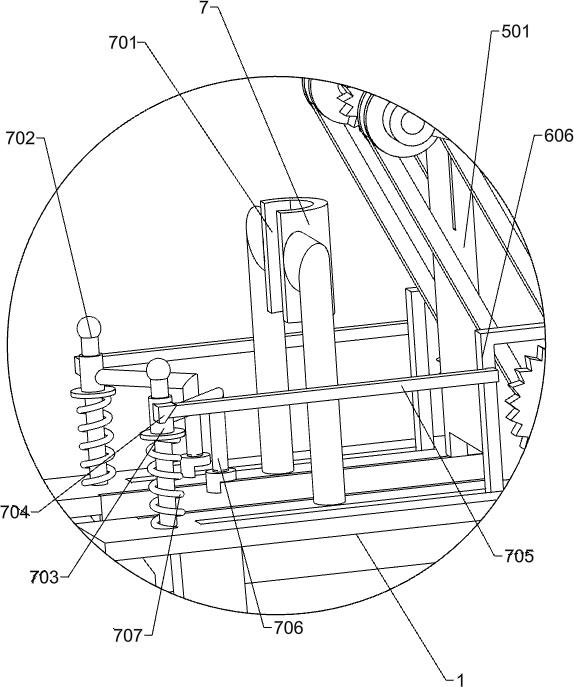

[0028] On the basis of Example 1, such as figure 1 and image 3 As shown, a stabilizing mechanism 7 is also included, and the stabilizing mechanism 7 includes an arc-shaped ferrule 701, a guide rod 702, a sleeve 703, a wedge block 704, an extruding rod 705, an L-shaped limit rod 706 and a pressure spring 707. The left side of the top of the groove plate 1 is connected with an arc-shaped ferrule 701, and the front and rear sides of the groove plate 1 on the left side of the arc-shaped ferrule 701 are connected with guide rods 702, and the guide rod 702 is slidably connected with a sleeve 703. 703 is connected with a wedge-shaped block 704, and the drive rack 606 is connected with an extruding rod 705. The extruding rod 705 cooperates with the wedge-shaped block 704. The right side of the sleeve 703 is connected with an L-shaped stop rod 706. The sleeve 703 and the groove A pressure spring 707 is connected between the plates 1 , and the pressure spring 707 is sleeved on the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com