A kind of hammer combination device

A combined device and hammer technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of labor-intensive, cumbersome operation process, easy displacement of hammer handle and hammer head, etc., and achieve labor-saving and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

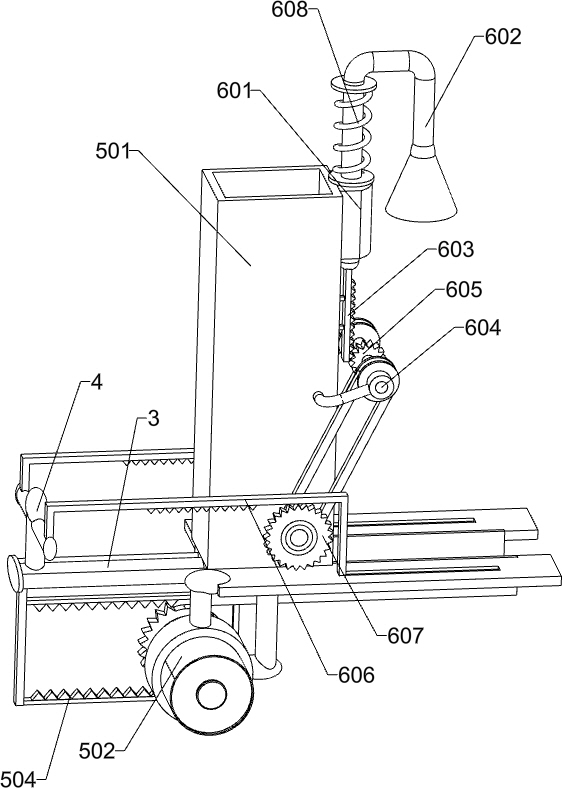

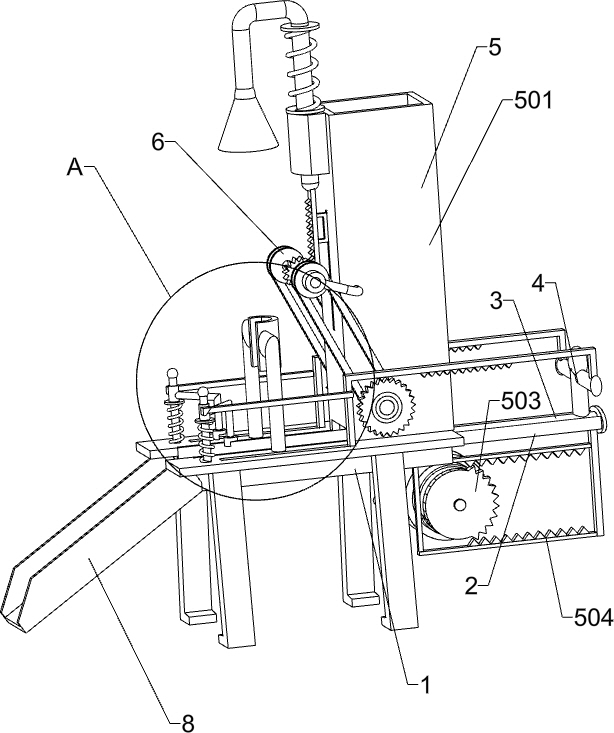

[0023] A hammer combination device such as Figure 1-2 As shown, it includes a groove plate 1, a guide frame 2, a push rod 3 and a connecting rod 4. The right side of the groove plate 1 is connected with a guide frame 2, and a push rod 3 is slidably connected to the guide frame 2. The top of the push rod 3 A connecting rod 4 is connected, and also includes a feeding mechanism 5 and a pressing mechanism 6 , a feeding mechanism 5 is arranged between the groove plate 1 and the push rod 3 , and a pressing mechanism 6 is arranged on the feeding mechanism 5 .

[0024] The unloading mechanism 5 includes a material frame 501, a deceleration motor 502, a sector gear 503 and a back-shaped rack 504. A material frame 501 is connected to the top right side of the groove plate 1, and a deceleration motor 502 is installed on the right side of the bottom of the groove plate 1. The deceleration motor A sector gear 503 is connected to the output shaft of 502 , and a return gear rack 504 is conn...

Embodiment 2

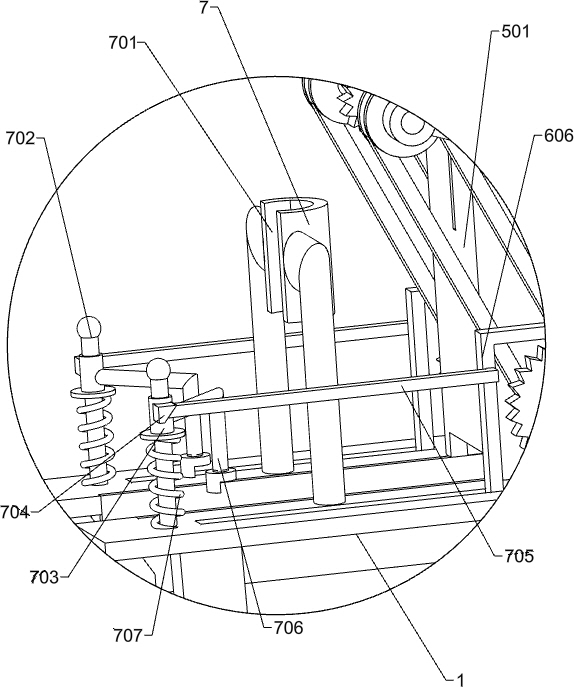

[0028] On the basis of Example 1, as figure 1 and image 3 As shown, it also includes a stabilizing mechanism 7. The stabilizing mechanism 7 includes an arc-shaped ferrule 701, a guide rod 702, a sleeve 703, a wedge-shaped block 704, a squeeze rod 705, an L-shaped limit rod 706 and a pressure spring 707. The concave The top left side of the groove plate 1 is connected with an arc-shaped ferrule 701, and the front and rear sides of the groove plate 1 on the left side of the arc-shaped ferrule 701 are connected with guide rods 702. The guide rod 702 is slidably connected with a sleeve 703. A wedge-shaped block 704 is connected to the 703, a squeeze rod 705 is connected to the transmission rack 606, the squeeze rod 705 cooperates with the wedge-shaped block 704, an L-shaped limit rod 706 is connected to the right side of the sleeve 703, and the sleeve 703 is connected to the groove A pressure spring 707 is connected between the plates 1 , and the pressure spring 707 is sleeved o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com