Method for direct forming tool die by multiple etchig and apparatus thereof

A forming knife and etching technology, applied in the field of over-etching direct forming knife mold, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

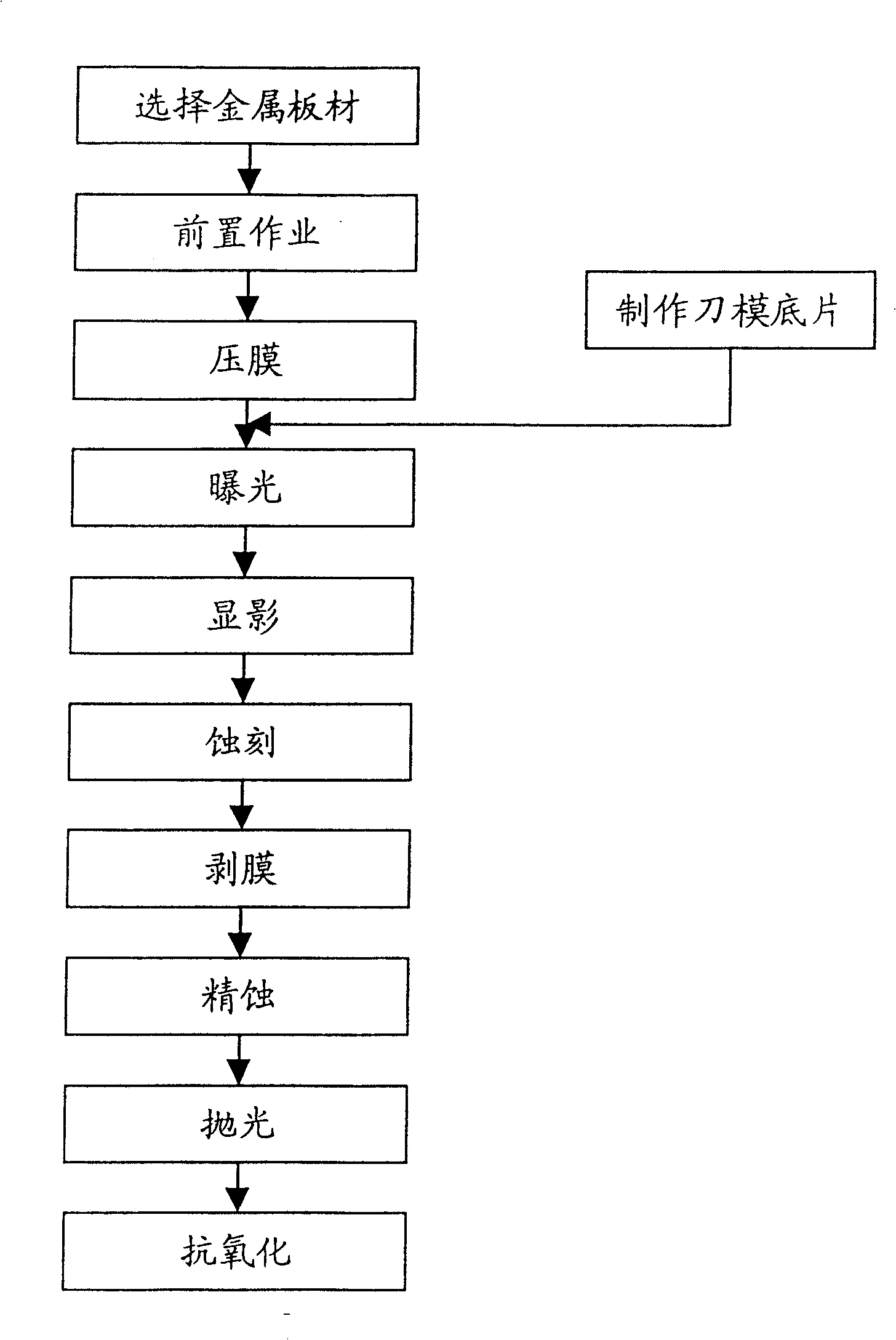

[0030] Such as figure 1 Shown, the method for multiple etching of the present invention direct forming knife mold comprises the following steps:

[0031] Select Sheet Metal Steps

[0032] Select sheet metal, such as heat-treated high-carbon steel, and cut it to size.

[0033] Prerequisite steps

[0034] Degrease and clean steel plates of appropriate dimensions.

[0035] Lamination step

[0036] After degreasing and cleaning the steel plates that have been cut into applicable sizes, the front and back of the steel plates are pressed with a film layer after degreasing and cleaning.

[0037] The backside film layer is any acid-resistant film, not specifically a photoresist film, to prevent etching.

[0038] The front film layer is a thin film such as a photoresist film that can be transferred to the negative of the cutting image and can produce chemical changes after exposure and development to block the effect of etching.

[0039] Make Die-Die Negatives

[0040]Make die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com