Fool-proof control system and method for server production labeling

A control system and control method technology, applied in labeling machines, labels, packaging, etc., can solve problems such as error-prone and low label sticking efficiency, and achieve the effects of avoiding label leakage, reliable design principles, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

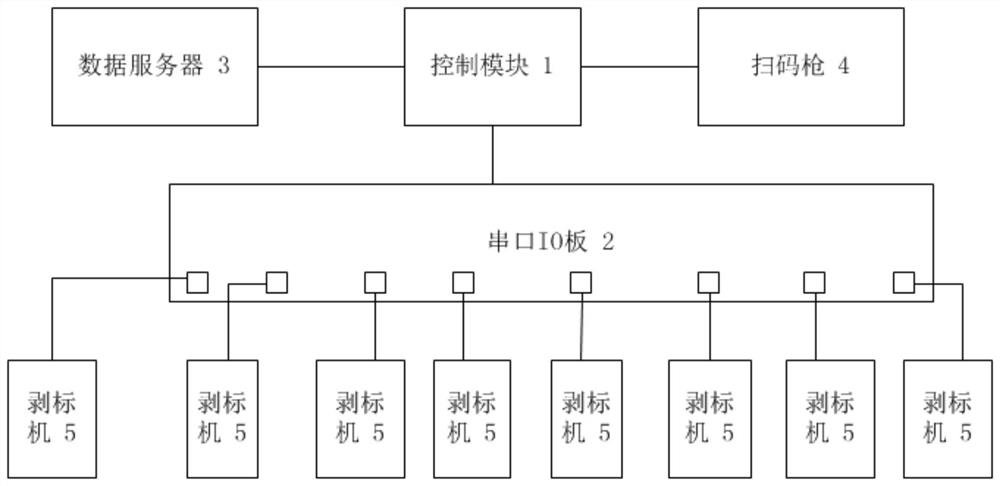

[0060] Such as figure 1 As shown, the present invention provides a server production and labeling fool-proof control system, including a control module 1;

[0061] The control module 1 is connected with a serial port IO board 2, a data server 3 and a code scanning gun 4;

[0062] The serial port IO board 2 is connected with several label stripping machines 5;

[0063] The control module 1 controls the code scanning gun 4 to obtain the SN code of the positioning server, and then obtains the label information corresponding to the SN code of the positioning server from the data server 3, and generates a BOM table; the label information includes the label PN code and label description information;

[0064] According to the PN codes of each label in the BOM table, the control module 1 sequentially selects the label stripping machine 5 with the same label PN code setting to produce the label, and detects whether the label that has been produced has been taken away.

[0065] In some ...

Embodiment 2

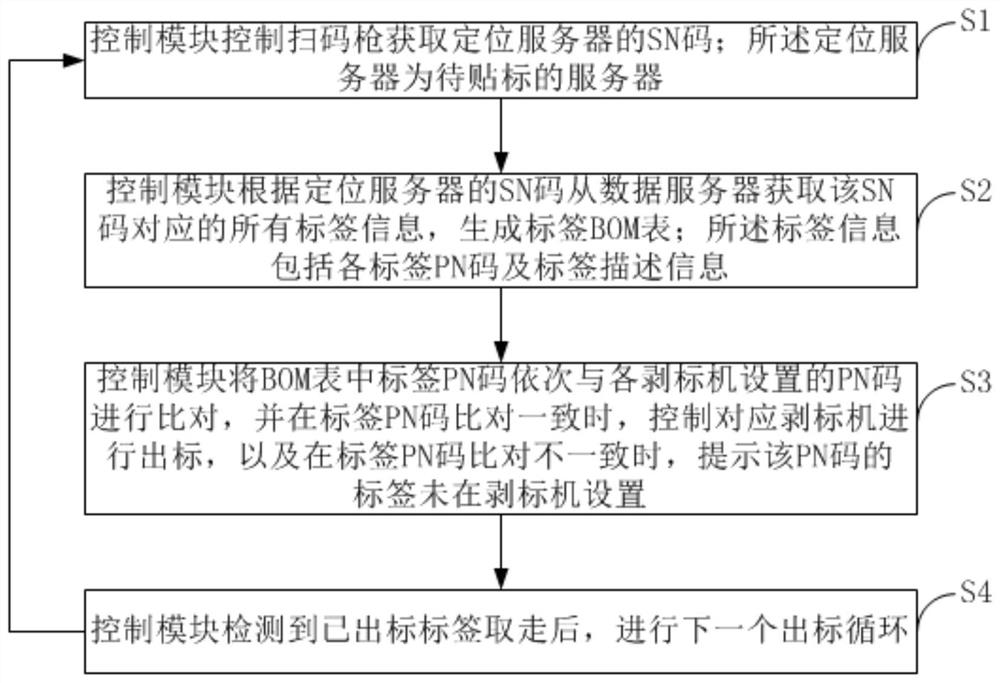

[0071] Such as figure 2 As shown, the present invention provides a server production and labeling fool-proof control method, including the following steps:

[0072] S1. The control module controls the code scanning gun to obtain the SN code of the positioning server; the positioning server is a server to be labeled;

[0073] S2. The control module obtains all label information corresponding to the SN code from the data server according to the SN code of the positioning server, and generates a label BOM table; the label information includes each label PN code and label description information;

[0074] S3. The control module compares the label PN code in the BOM table with the PN code set by each label stripping machine in turn, and when the label PN code is consistent, controls the corresponding label stripping machine to output the label, and compares the label PN code When it is inconsistent, it will prompt that the label of the PN code is not set in the label stripping ma...

Embodiment 3

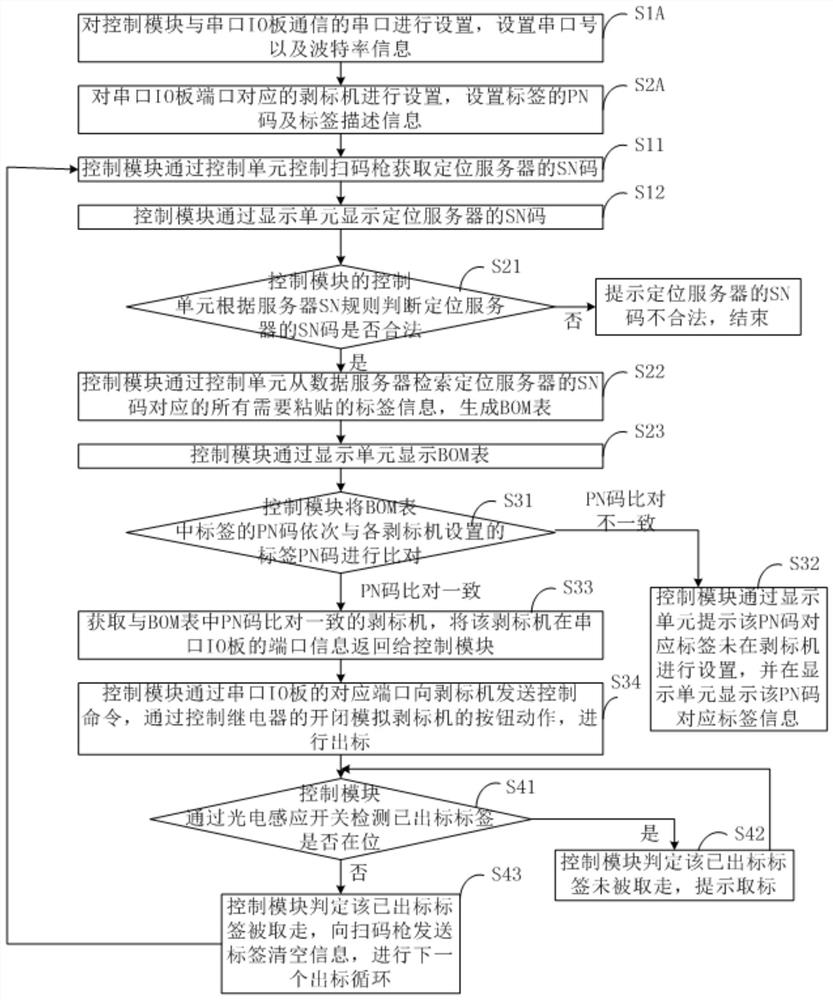

[0077] Such as image 3 As shown, the present invention provides a server production and labeling fool-proof control method, including the following steps:

[0078] S1A. Set the serial port for communication between the control module and the serial port IO board, set the serial port number and baud rate information;

[0079] S2A. Set the label stripping machine corresponding to the port of the serial port IO board, and set the PN code and label description information of the label;

[0080] S1. The control module controls the code scanning gun to obtain the SN code of the positioning server; the positioning server is a server to be labeled; the specific steps are as follows:

[0081] S11. The control module controls the code scanning gun to obtain the SN code of the positioning server through the control unit;

[0082] S12. The control module displays the SN code of the positioning server through the display unit;

[0083] S2. The control module obtains all label informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com