Parallel prestressed steel wire winding technology

A technology of prestressed steel wire and winding process, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., to achieve the effect of shortening the winding cycle and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

[0017] A kind of side-by-side prestressed steel wire winding process provided by the present invention, the steps are as follows:

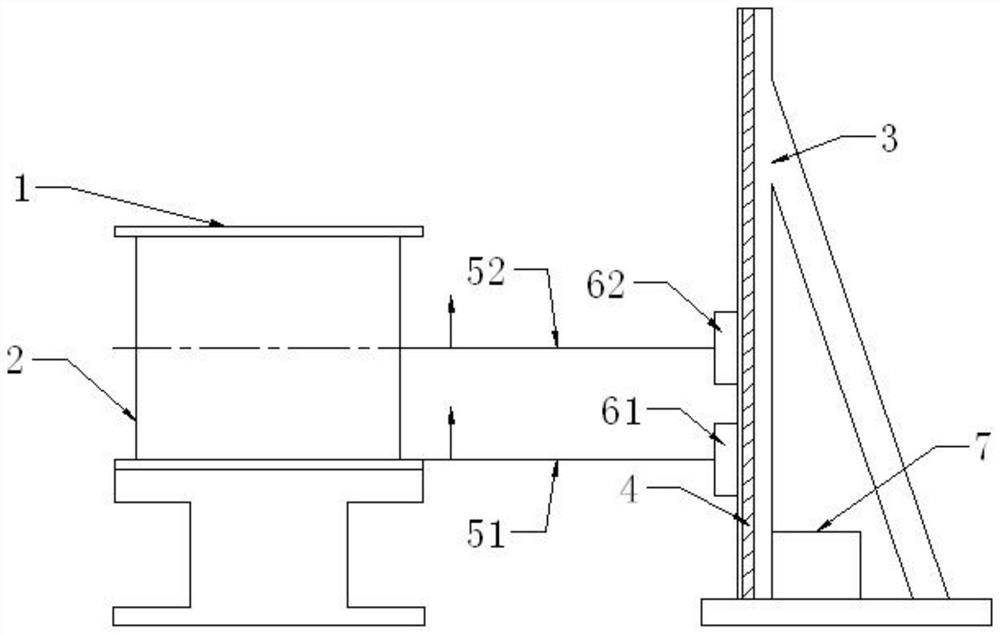

[0018] S1. Divide the steel wire trough 2 vertically and equally according to the number of pay-offs, and the bottom line position of each part is the starting position of each steel wire;

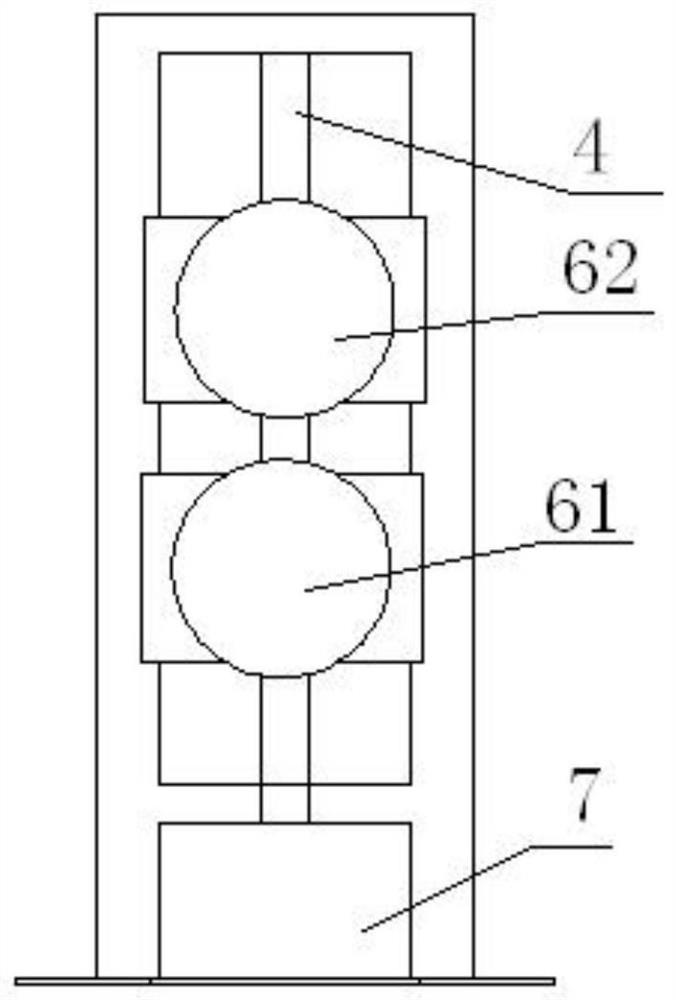

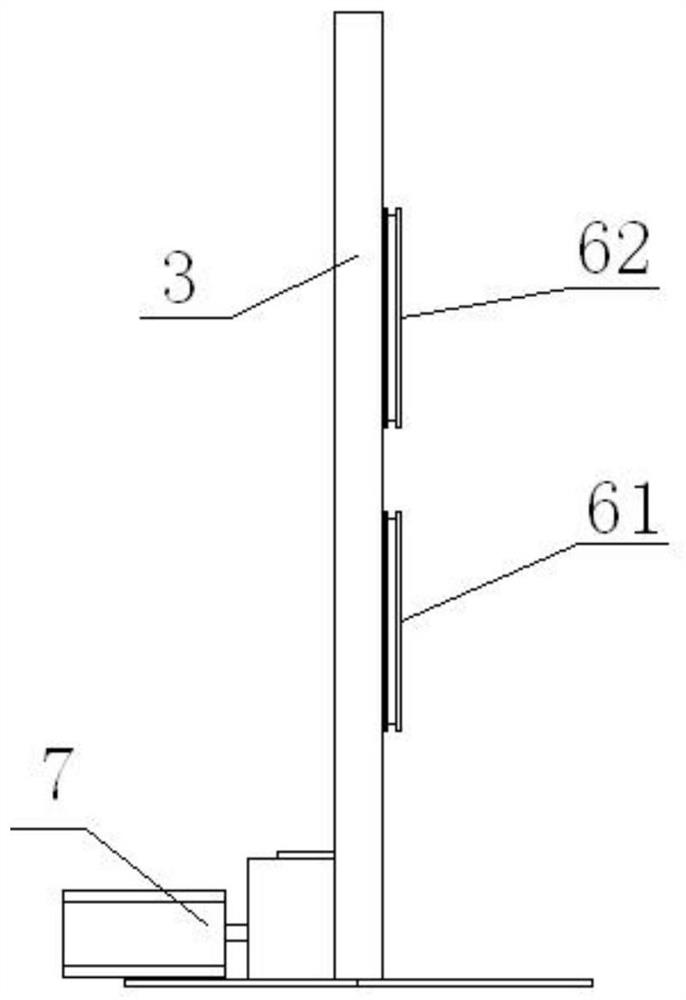

[0019] S2. Each steel wire is connected with a pay-off device. The pay-off device is installed on the same lead screw 4. The drive motor 7 runs in forward rotation and drives the lead screw 4 to rotate. wiring;

[0020] S3, when the steel wire positioned below reaches the bottom line position of the steel wire above, the driving motor 7 is changed from forward rotation to reverse rotation, and reverse wiring is carried ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap