A sensor and its sensor support

A sensor support and support technology, which is applied in the direction of instruments, measuring instrument components, connecting components, etc., can solve the time-consuming and labor-intensive problems of manpower gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

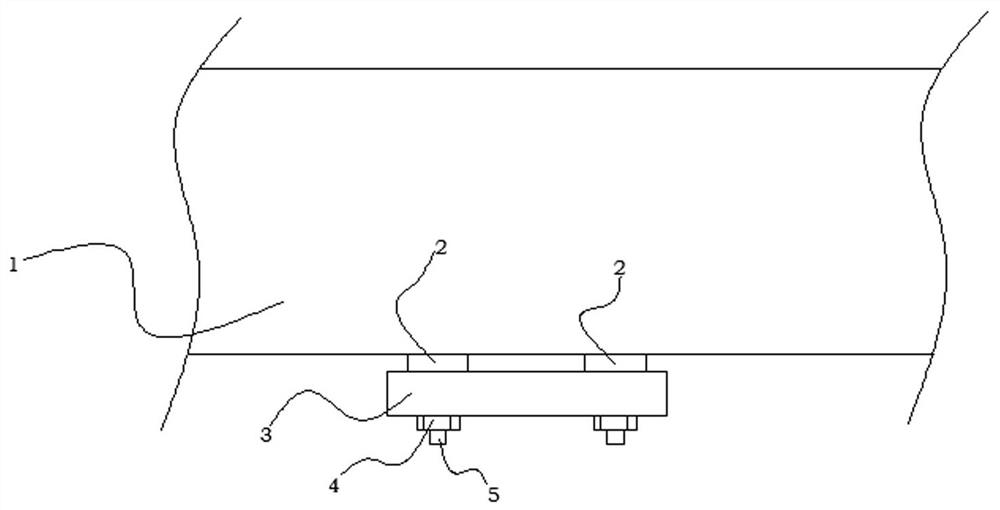

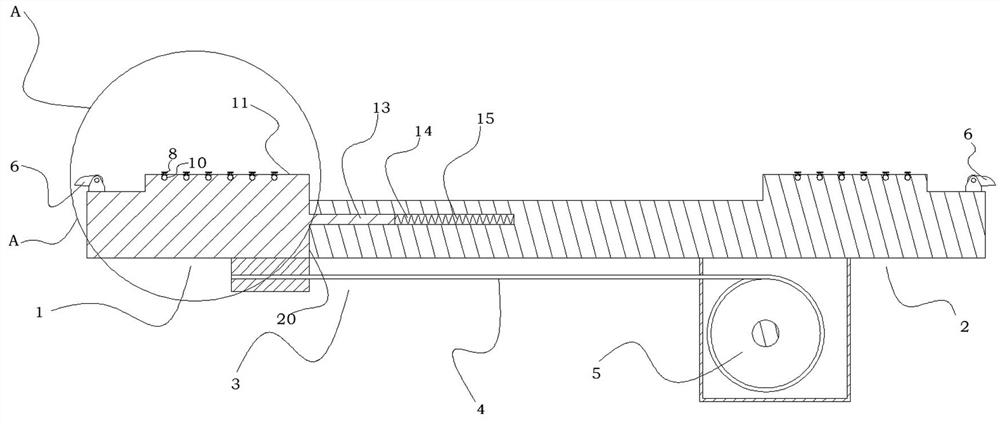

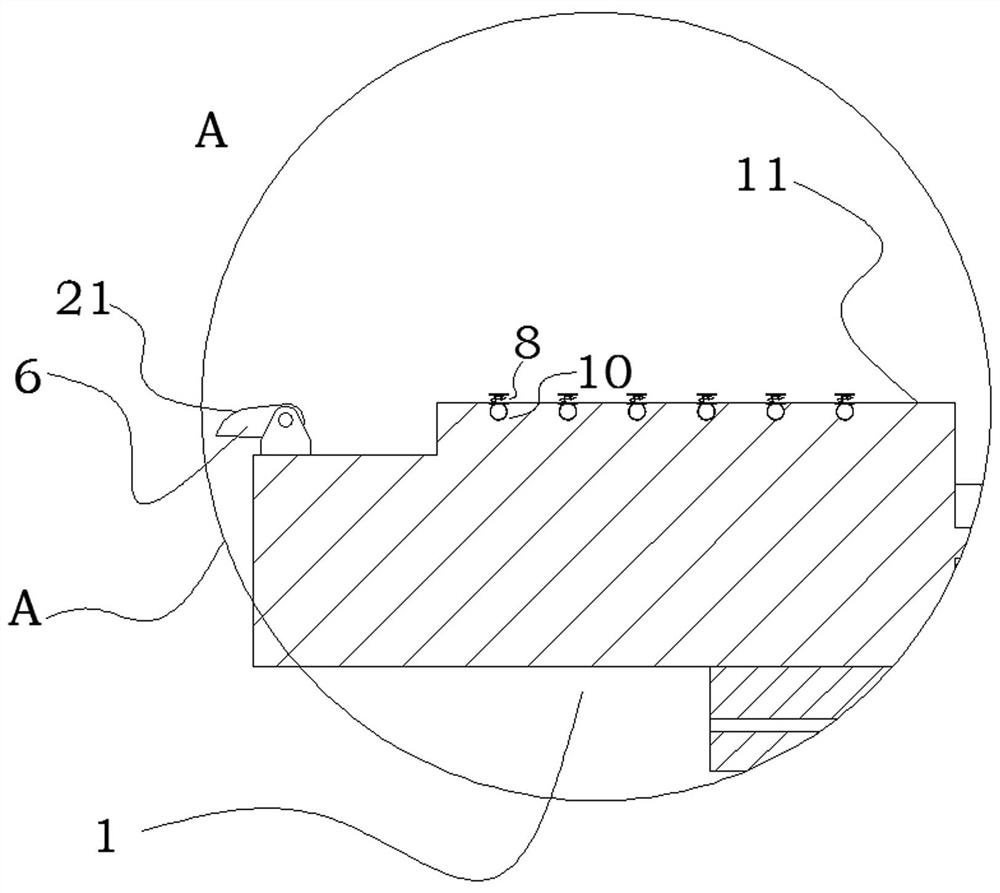

[0027] Examples of sensors are Figure 2~6 Shown:

[0028] The sensor includes a sensor support, the sensor support includes a support body, the support body includes a first leg part 1 and a second leg part 2 arranged left and right, and the first leg part 1 is aligned with the second leg part along the left and right direction. 2 Guide movement cooperation, specifically the second leg part is provided with a guide hole 14 whose guiding direction extends along the left and right directions, and the first leg part has a guide rod extending into the guide hole and slidingly matched with the guide hole 13. The right end face of the first leg part constitutes the abutting positioning surface 20 for abutting against the second leg part, and a positioning spring 15 is arranged in the guide hole, and the positioning spring 15 is an extension spring, and the right end of the positioning spring is in contact with the guide. The hole bottom of the hole is fixedly connected, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com