A method for measuring the transition process characteristics of aircraft boundary layer in hypersonic flight test

A flight test, hypersonic technology, applied in the testing of machine/structural components, measurement devices, aerodynamic tests, etc., can solve the problems of transition information of a single boundary layer, obtain a small amount of information, etc., to improve the level of understanding and measure the area Reasonable, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

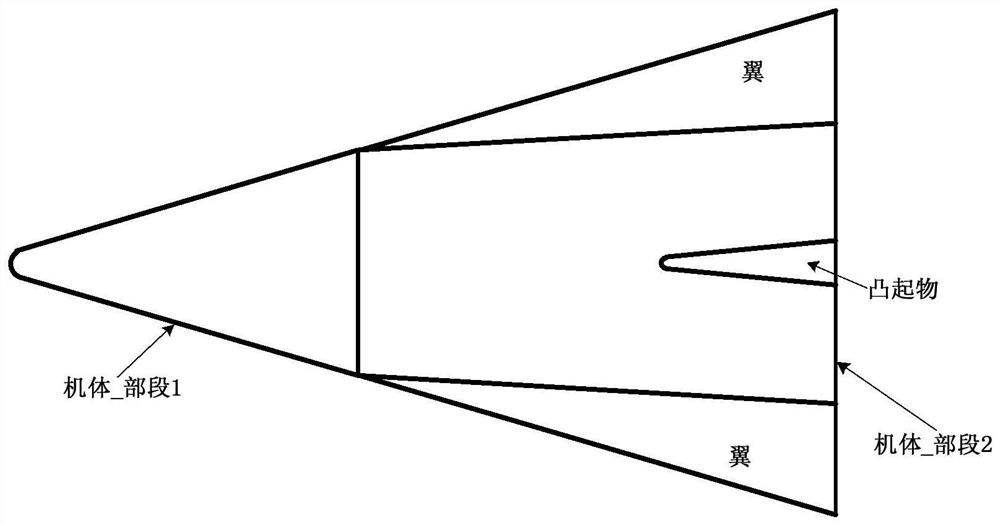

[0035] Taking the measurement of the transition process of the boundary layer on the windward side of an aircraft with a typical shape as an example, the specific implementation of the present invention is described. figure 1 It is a schematic diagram of the shape of the aircraft. The aircraft is a typical "body + wing" configuration. The body is composed of two sections, section 1 and section 2. The profiles of the sections are not consistent and the protrusions (eg control rudders) are on section 2. The implementation steps of the hypersonic flight test vehicle boundary layer transition process information measurement method provided by the present invention are as follows:

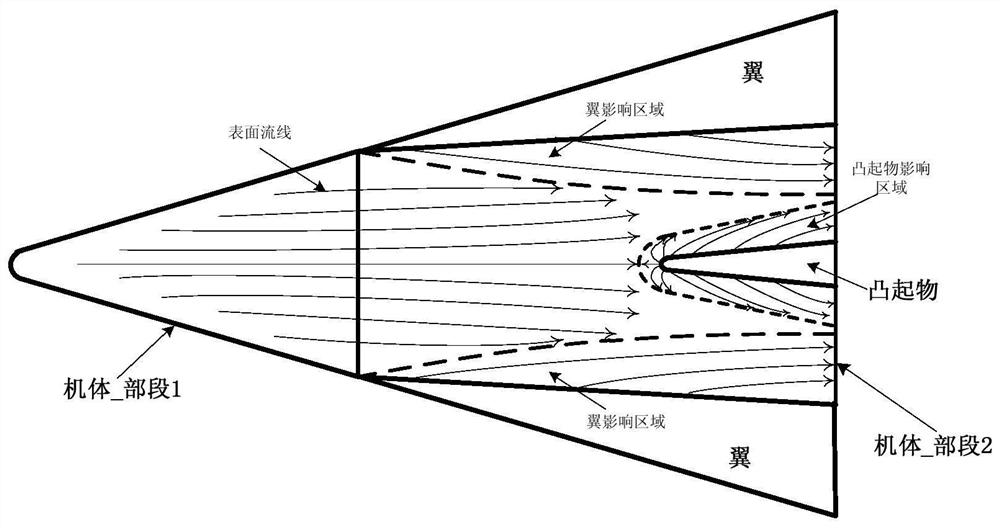

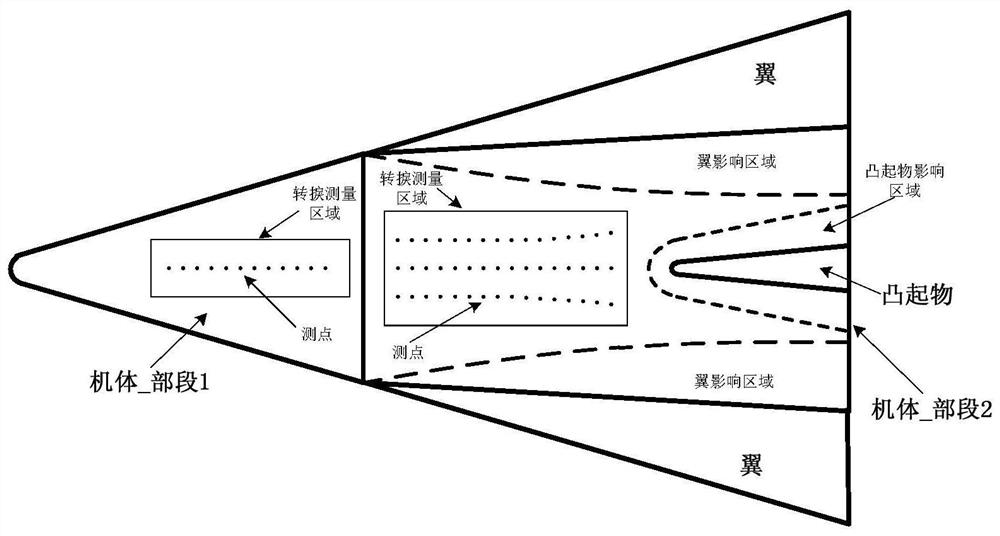

[0036] 1) First utilize CFD numerical method (known technology in the art) to carry out the simulation calculation of the flow field around the aircraft, by fl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap